Winch support

A winch support and mobile support technology, applied in ships, cargo handling equipment, passenger handling equipment, etc., can solve problems such as poor adaptability of the winch support, and achieve the effect of improving applicability, increasing distance, and reducing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] An embodiment of the present invention provides a winch support, which is used for installing and supporting a winch drum.

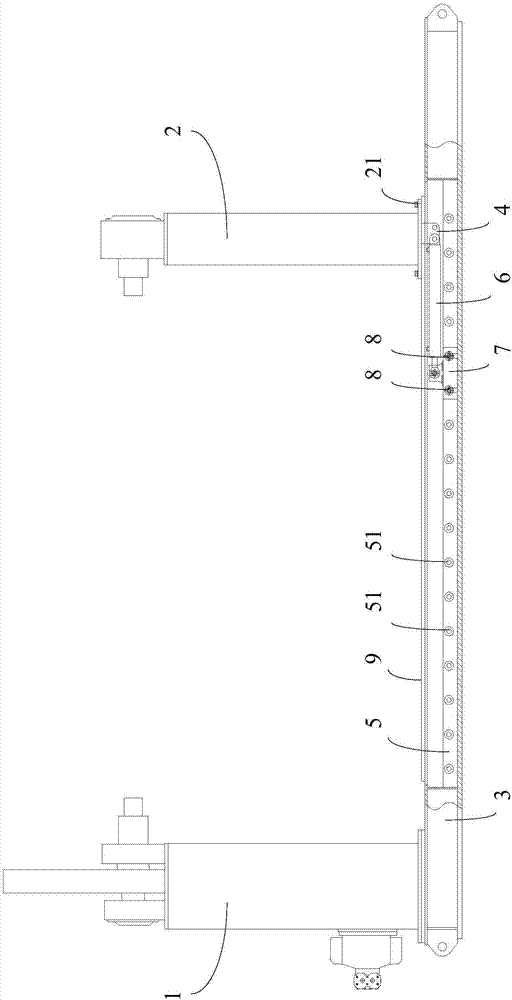

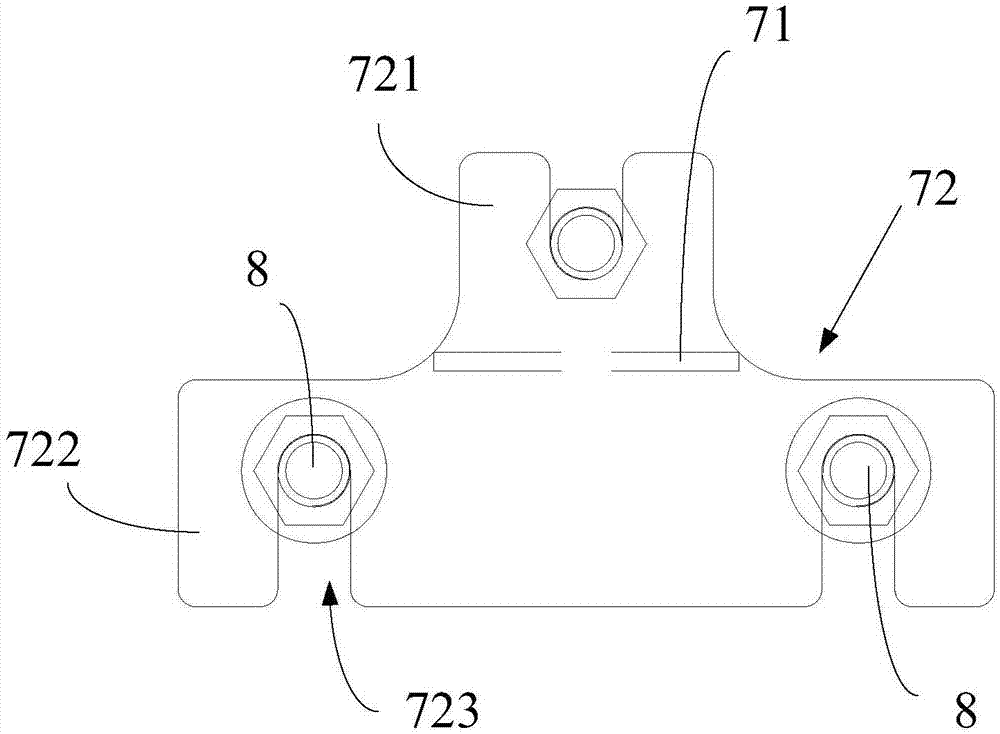

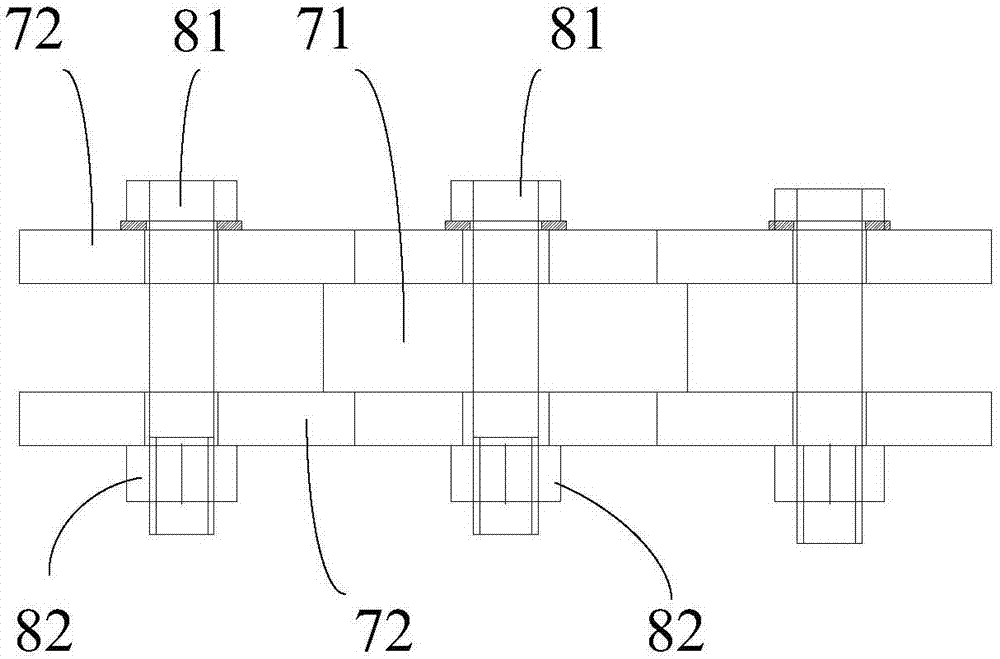

[0029] figure 1 Schematic diagram of the structure of the winch support, such as figure 1 As shown, the winch support includes a fixed support 1, a mobile support 2 and a base 3, the fixed support 1 is fixed on the base 3, and the top of the base 3 is provided with a through groove extending from the mobile support 2 towards the fixed support 1, and the mobile support 2 The bottom is provided with a slider 4, and the slider 4 is slidably inserted into the through groove. There is a track part 5 extending along the length direction of the through groove in the base 3, and the track part 5 is arranged opposite to the through groove. The longitudinal direction of the component 5 is equidistantly provided with a plurality of installation holes 51, and the oil cylinder 6 is installed on the slider 4, and the expansion and contraction direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com