High-strength and high-toughness cellulose hydrogel with force-induced optical anisotropic structure and preparation method of high-strength and high-toughness cellulose hydrogel

A technology of cellulose hydrogel and cellulose gel, applied in polymer functional materials, chemical and chemical fields, can solve the problems of long time, increase the difficulty of industrial application, reduce the efficiency of material preparation, etc., and achieve the effect of obvious optical anisotropy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Preparation of regenerated cellulose:

[0029] For the preparation method of cellulose solution, see Macromolecules 2008. 23, 9345-9351. The cellulose solvent is placed in a refrigerator for pre-cooling, the cellulose is put into the pre-cooled solvent, and the cellulose solution is obtained after vigorous stirring. The obtained cellulose solution is centrifuged under temperature control and high speed rotation to remove bubbles and undissolved impurities, and finally a transparent cellulose solution is obtained.

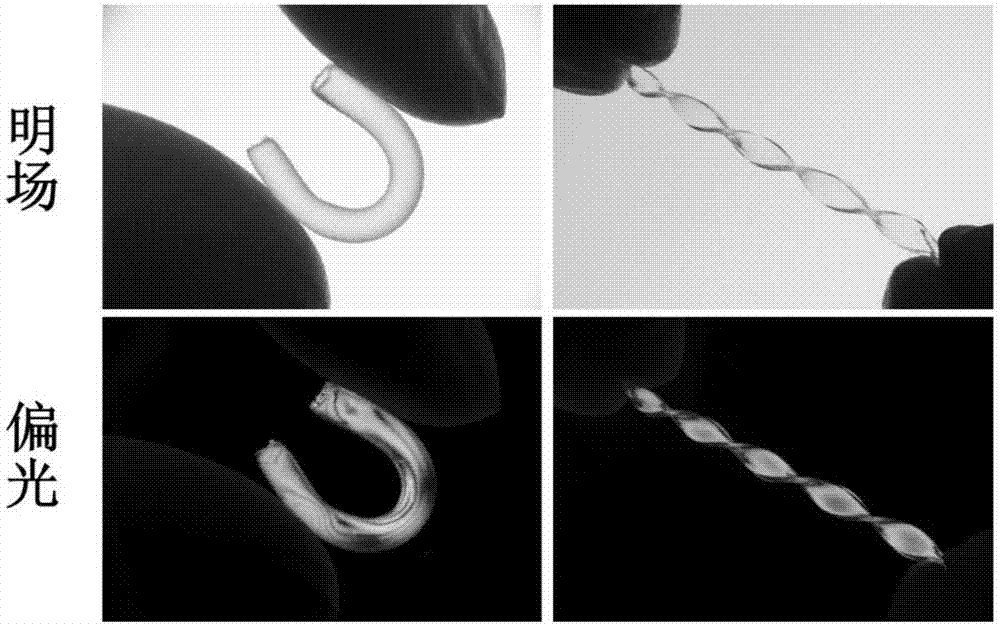

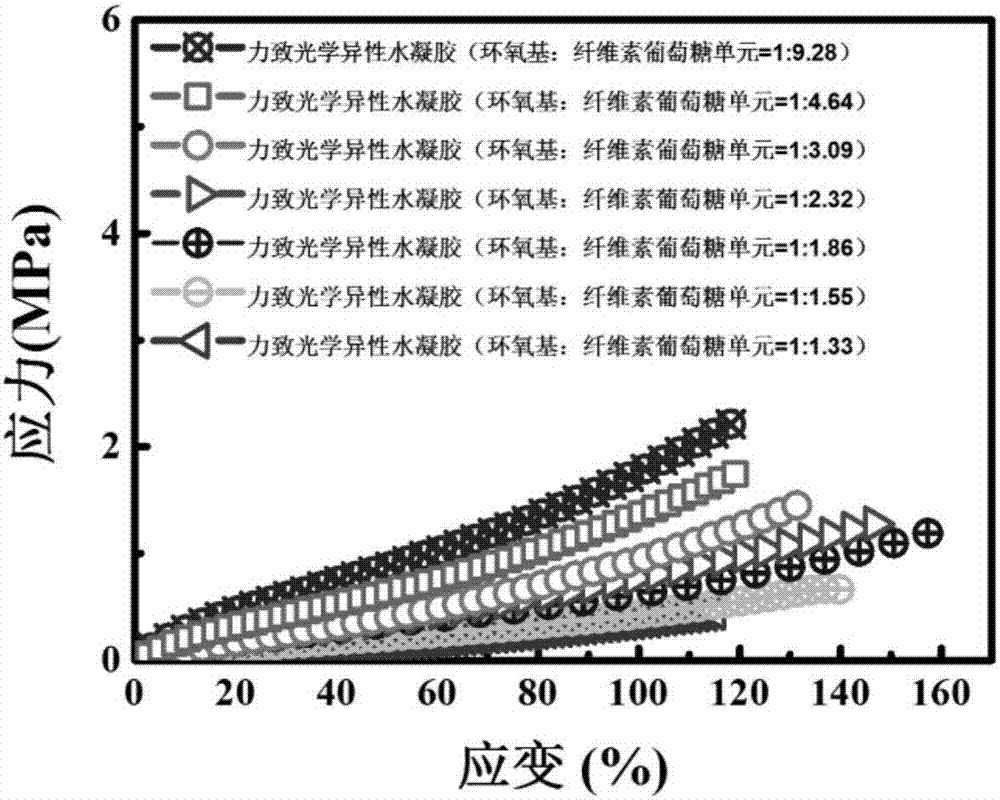

Embodiment 1

[0031] A regenerated cellulose solution with a concentration of 5 wt% was prepared. Add epichlorohydrin (molar ratio of epichlorohydrin active functional groups to cellulose glucose unit = 1:2.32) at 10°C, stir evenly, centrifuge and degas, then transfer to the mold, and place it at room temperature for 8 hours to obtain partial chemically cross-linked fibers Then put the gel in a 2 mol / L sulfuric acid solution for 0.1 min to quickly terminate the chemical cross-linking reaction and introduce a physical cross-linking network, and finally wash to neutral to obtain a hydrogel with high light transmittance, high toughness and obvious The force causes the optical heterosexual behavior, that is, the forced state hydrogel produces obvious rainbow-colored polarized light behavior under polarized light.

Embodiment 2

[0033] A regenerated cellulose solution with a concentration of 5 wt% was prepared. Add epichlorohydrin (molar ratio of epichlorohydrin active functional groups to cellulose glucose unit = 1:2.32) at 10°C, stir evenly, centrifuge and degas, then transfer to the mold, and place it at room temperature for 8 hours to obtain partial chemically cross-linked fibers Then put the gel in a 2 mol / L sulfuric acid solution for 5 minutes to quickly terminate the chemical cross-linking reaction and introduce a physical cross-linking network, and finally wash to neutrality to obtain a hydrogel with high light permeability, high toughness and obvious Forced to optically heterosexual behavior, that is, the forced state hydrogel produces obvious rainbow-colored polarized light behavior under polarized light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com