Preparation method of regenerated cellulose fiber with high orientation, high strength and high toughness and regenerated cellulose fiber with high orientation, high strength and high toughness

A technology of regenerated cellulose and high orientation, applied in the fiber field, can solve the problems of environmental pollution, expensive solvents, harsh preparation conditions, etc., and achieve the effect of low raw material, high orientation degree and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] According to one aspect of the present invention, the present invention provides a kind of preparation method of highly oriented high tenacity regenerated cellulose fiber, comprises the steps:

[0043] (a) mixing the regenerated cellulose solution with a crosslinking agent to obtain a mixed solution of regenerated cellulose and a crosslinking agent;

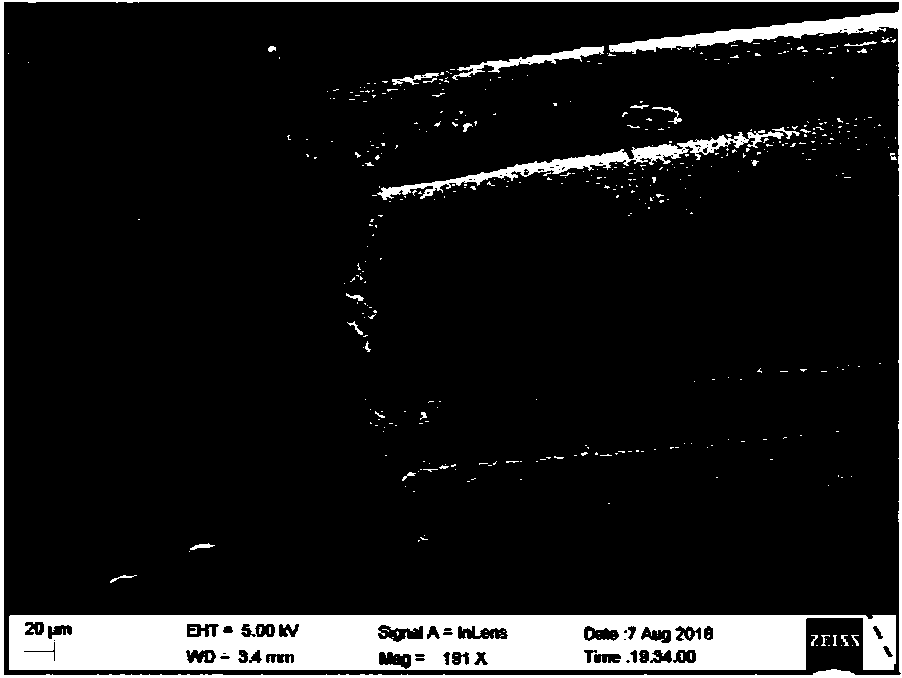

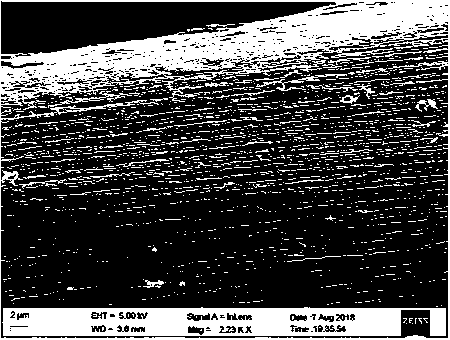

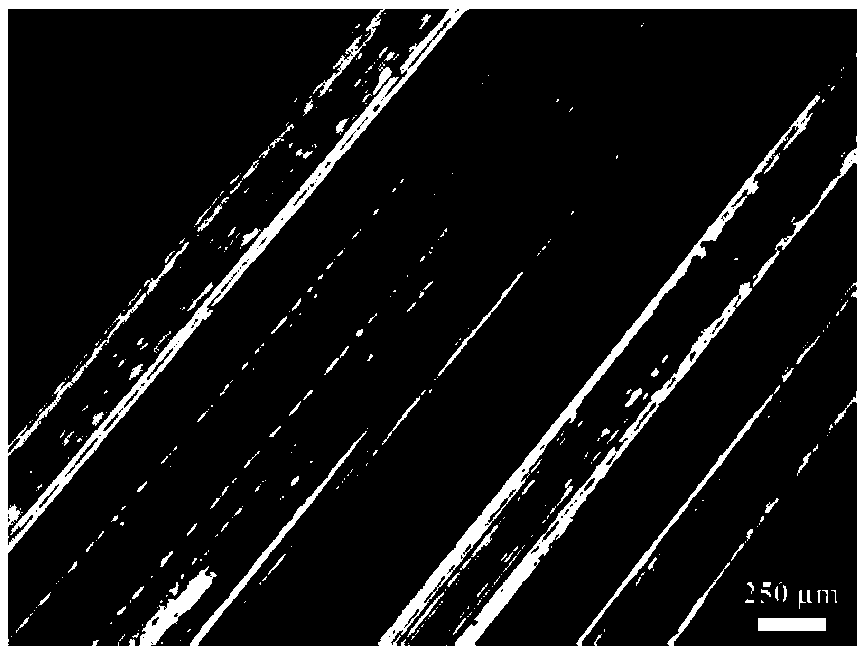

[0044] (b) spinning the mixed solution of regenerated cellulose and crosslinking agent, and solidifying it through a coagulation bath to obtain wet regenerated cellulose fibers;

[0045] (c) confinement drying of wet regenerated cellulose fibers to obtain regenerated cellulose fibers with high orientation and high tenacity.

[0046] In step (a), the crosslinking reaction is carried out at the regenerated viscose temperature.

[0047] The method for preparing regenerated cellulose fibers with high orientation and high strength and toughness provided by the present invention first cross-links the regenerated cellulose solut...

Embodiment 1

[0071] This embodiment provides a kind of regenerated cellulose fiber, which is prepared according to the following steps:

[0072] (1) Add 30mL of epichlorohydrin (mass concentration: 99%) to 1000mL of 5wt% regenerated cellulose (number average molecular weight: 100,000) solution at 0°C, stir evenly, and centrifuge to defoam to obtain a mixed solution;

[0073] (2) Put the mixed solution in the barrel of the wet spinning machine, apply a pressure of 0.8 MPa to the barrel, make the mixed solution pass through the spinning nozzle with a diameter of 120 μm, and enter the coagulation bath of a sulfuric acid solution with a concentration of 0.2 mol / L to stop quickly Chemical cross-linking reaction and curing to obtain wet regenerated cellulose fibers;

[0074] (3) After the wet regenerated cellulose fiber is washed with water, the two ends of the wet fiber are fixed after being wound on the upper filament tube, and the regenerated cellulose fiber is obtained by confinement drying ...

Embodiment 2

[0076] This embodiment provides a kind of regenerated cellulose fiber, which is prepared according to the following steps:

[0077] (1) Add 10 mL of epichlorohydrin (mass concentration: 99%) to 1000 mL of 6 wt % regenerated cellulose (number average molecular weight: 100,000) solution at 5° C., stir evenly, and centrifuge to defoam to obtain a mixed solution;

[0078] (2) Put the mixed solution in the barrel of the wet spinning machine, apply a pressure of 0.4 MPa to the barrel, make the mixed solution pass through the spinning nozzle with a diameter of 160 μm, and enter the coagulation bath of the phytic acid solution with a concentration of 0.5 mol / L to rapidly Terminate the chemical crosslinking reaction and solidify to obtain wet regenerated cellulose fibers;

[0079] (3) After the wet regenerated cellulose fiber is washed with water, the two ends of the wet fiber are fixed after being wound on the upper filament tube, and the regenerated cellulose fiber is obtained by con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com