Vegetable oil-based polyols type biodegradable UV-curing adhesive and preparation method

A vegetable oil-based, polyol-based technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of curing materials that cannot be biodegraded, biodegradable performance, environmental hazards, etc., and achieve excellent reliability Biodegradability, solution to environmental pollution problems, effect of relieving pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

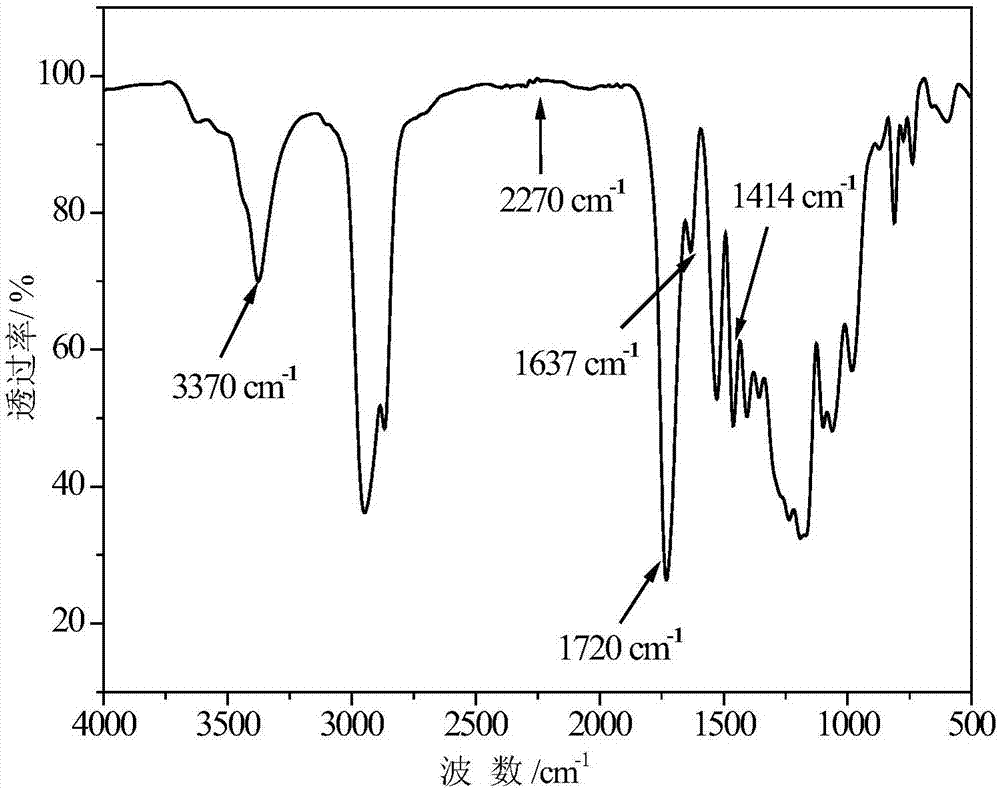

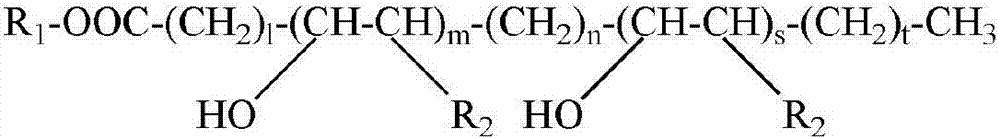

Method used

Image

Examples

Embodiment 1

[0065] (1) Synthesis of vegetable oil-based PU prepolymer: Add 1 mol of vegetable oil-based polyol in sequence to the reaction kettle, stir and heat up to 115°C, dehydrate under reduced pressure for 2 hours and then cool down to 65°C, then add 1mol of hexamethylene Dibutyltin dilaurate and 0.01mol catalyzer dibutyltin dilaurate, pay attention to controlling the rate of addition, and preferably drop it in 2 hours. After 2 hours of reaction, take a sample to measure the -NCO group content until the theoretical value is reached, and the first step of reaction ends;

[0066] (2) Synthesis of UV-curable vegetable oil-based PUA prepolymer: the intermediate product obtained in step (1) is cooled to 55°C, and a mixture of 1mol hydroxyethyl acrylate and 0.02mol inhibitor p-hydroxyanisole is added under stirring , react for 3 hours, track the content of -NCO group, when the free -NCO content is lower than 0.1%, stop the reaction, steam the solvent and cool down the material, and obtain t...

Embodiment 2

[0071] (1) Synthesis of vegetable oil-based PU prepolymer: Add 1 mol of vegetable oil-based polyols into the reactor in sequence, stir and heat up to 125°C, dehydrate under reduced pressure for 3 hours, then cool down to 75°C, then add 1.2mol of toluene di The mixture of isocyanate and 0.03mol catalyst dibutyltin dilaurate, pay attention to control its drop rate, preferably drop it in 3h, after reacting for 4h, take a sample to measure the content of -NCO group until it reaches the theoretical value, and the first step reaction ends;

[0072] (2) Synthesis of UV-curable vegetable oil-based PUA prepolymer: the intermediate product obtained in step (1) is cooled to 45°C, and a mixture of 1.1mol hydroxypropyl acrylate and 0.01mol inhibitor p-hydroxyanisole is added under stirring. The mixture was reacted for 3 hours, and the content of the -NCO group was tracked. When the free -NCO content was lower than 0.1%, the reaction was stopped, the solvent was evaporated, the solvent was c...

Embodiment 3

[0076] (1) Synthesis of vegetable oil-based PU prepolymer: Add 1 mol of vegetable oil-based polyols into the reaction kettle sequentially, stir and heat up to 120°C, dehydrate under reduced pressure for 2.5 hours and cool down to 70°C, then add 1.05mol of The mixture of phenylene diisocyanate and 0.01mol catalyst dibutyltin dilaurate, pay attention to control the dropping rate, preferably drop it in 2.5h, after the reaction for 3h, take a sample to measure the -NCO group content until it reaches the theoretical value, and the first step reaction ends;

[0077] (2) Synthesis of UV-curable vegetable oil-based PUA prepolymer: the intermediate product obtained in step (1) is cooled to 45°C, and a mixture of 1mol hydroxybutyl acrylate and 0.01mol inhibitor p-hydroxyanisole is added under stirring , react for 2 hours, track the content of -NCO group, when the free -NCO content is lower than 0.1%, stop the reaction, steam the solvent and cool down the material, and obtain the vegetabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com