Paper forming mechanism for guiding pulp

A technology of forming mechanism and paper, applied in paper machine, wet end of paper machine, paper making and other directions, can solve the problems of low evenness and affect the quality of paper, and achieve the effect of uniformity, good paper forming effect and good forming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

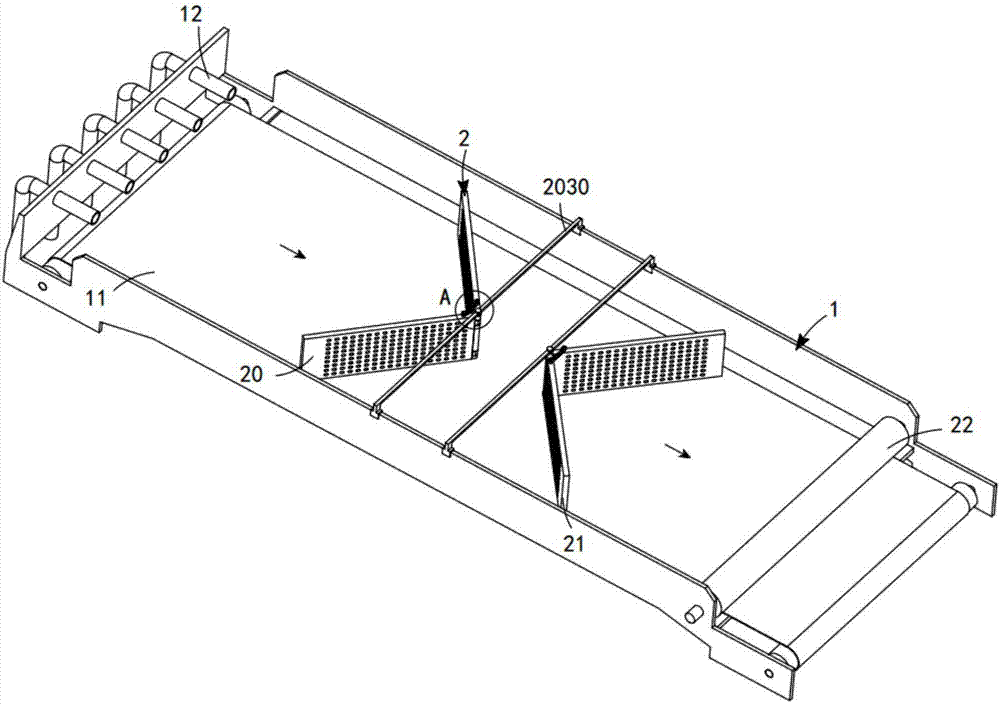

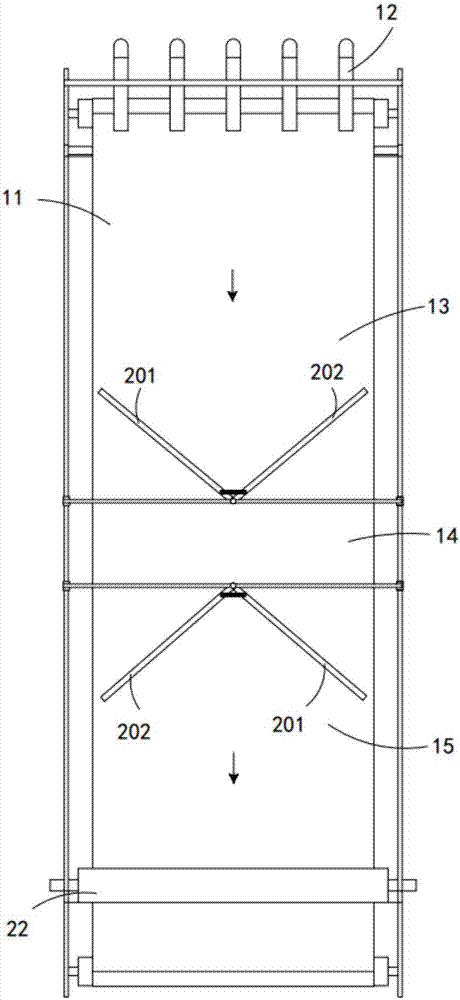

[0035] like figure 1 and figure 2 As shown, a paper forming mechanism for diverting slurry includes a feeding channel 1, and a forming net 11 is rotated inside the feeding channel 1, and the feeding ends of the feeding channel 1 are equidistantly arranged along the width direction thereof. There are several feed pipes 12, and the feed pipes 12 are all located above the forming net 11, and also include:

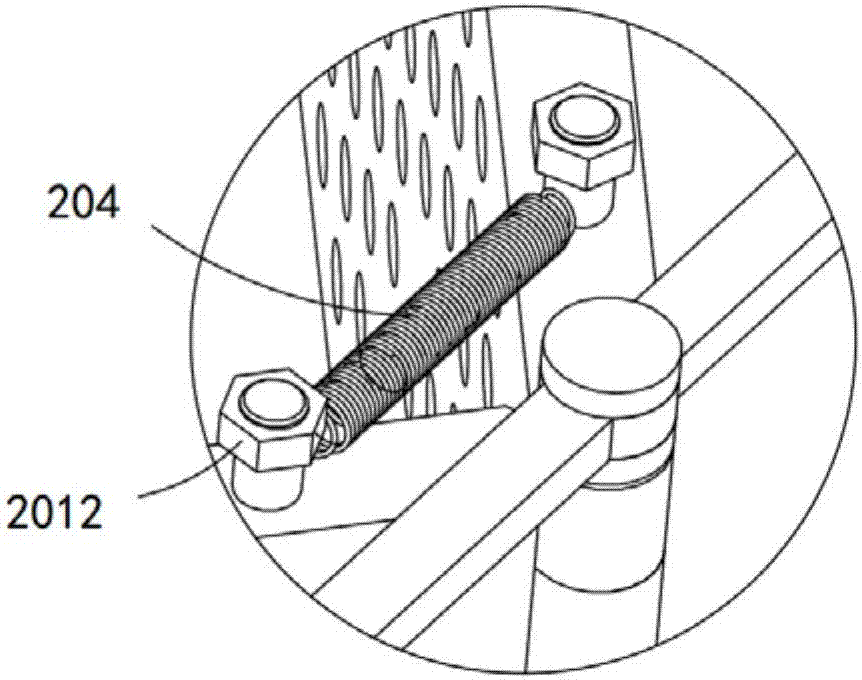

[0036] The flow guide forming assembly 2, the flow guide forming assembly 2 is arranged in the material delivery channel 1, and is arranged above the forming net 11, the flow guide forming assembly 2 includes a first flow guide 20, a second guide flow member 21 and pressure roller 22, the first flow guide member 20 and the second flow guide member 21 guide the slurry, and divide the conveying channel 1 into front and rear 1 along the conveying direction The first zone 13 , the second zone 14 and the third zone 15 ; the pressing roller 22 is arranged at the output end of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com