Technique for manufacturing high-performance printing paper

A technology of printing paper and production process, which is applied in papermaking, paper coating, papermaking machines, etc. It can solve the problems of strength, paper formation and bulk thickness, which are difficult to balance and balance, and achieve full and bright colors and printing ink. Uniform, simple and clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

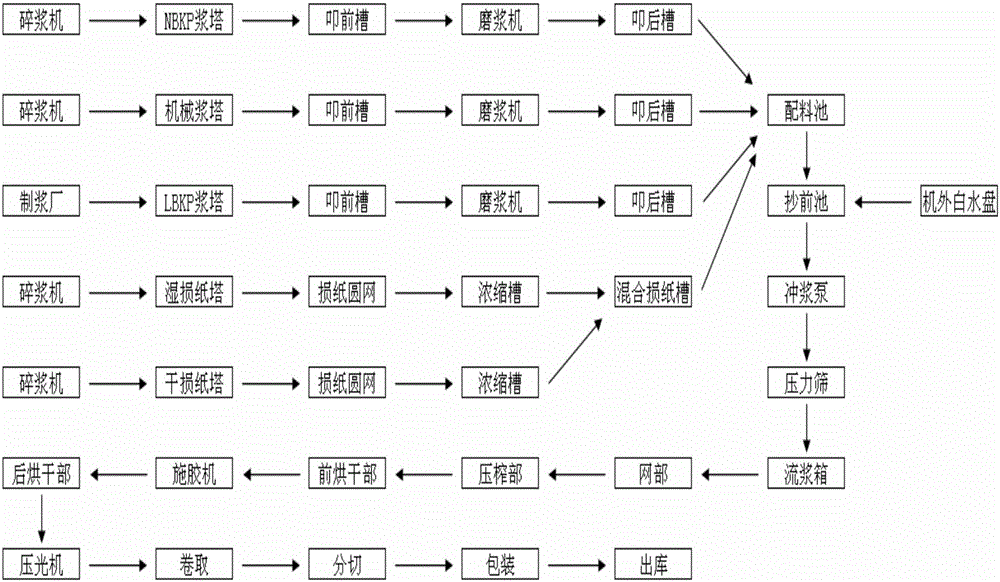

[0021] Such as figure 1 An embodiment of the production process of high-performance printing paper of the present invention is shown, comprising the following steps:

[0022] (1) Disintegrate the bleached kraft softwood pulp board into the NBKP pulp tower after being disintegrated by the pulper, and then enter the refiner through the pre-knocking tank for refining, and then send it to the back-knocking tank for storage for later use. The freeness of pulp is 330-360CSF, and the refining concentration is 3.9-4.5%;

[0023] (2) The bleached kraft hardwood pulp from the pulp mill or the bleached kraft hardwood pulp board is sent to the LBKP pulp tower after being disintegrated by the pulper, and then enters the refiner for refining through the front groove , and then sent to the knocking tank for storage for subsequent use, wherein the freeness of the ground pulp is 340-360CSF, and the refining concentration is 4.8-5.2%;

[0024] (3) Send the mechanical pulp from the pulp mill i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| opacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com