Unbleached full-bamboo paste food packaging body paper and production process

A technology of food packaging and bamboo pulp, which is applied in the field of pulp and paper making, can solve the problems of organic chloride wastewater, antibacterial agents, human health hazards, etc., and achieve the effects of reducing pollution, good water and oil resistance, and reducing the use of antibacterial agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

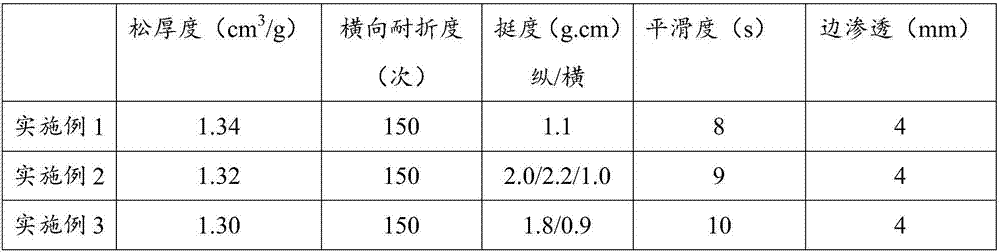

Examples

Embodiment 1

[0029] Unbleached whole bamboo pulp food packaging base paper, the food packaging base paper is made of bamboo pulp and chemical auxiliary materials, and the chemical auxiliary materials include the following components in parts by weight: 0.008 parts of aluminum sulfate, 0.018 parts of rosin gum, talcum powder 0.03 parts, retention aid 0.0003 parts, organic particles 0.0002 parts, silica sol 0.002 parts, defoamer 0.0003 parts.

[0030] Preferably, the retention aid is polyacrylamide.

[0031] Preferably, the food packaging base paper is used for packaging food.

[0032] The manufacturing process based on unbleached full bamboo pulp food packaging base paper comprises the following steps:

[0033] a. Pulp preparation: send the natural color pulp of the whole bamboo pulp to the storage tank, and then undergo beating respectively to obtain refined bamboo pulp with a pulp concentration of 4.0% and a beating degree of 40-55°SR;

[0034] b. 0.008 part of aluminum sulfate, 0.0018 ...

Embodiment 2

[0044] Unbleached whole bamboo pulp food packaging base paper, the food packaging base paper is made of bamboo pulp and chemical auxiliary materials, and the chemical auxiliary materials include the following components in parts by weight: 0.01 part of aluminum sulfate, 0.018 part of rosin gum, talcum powder 0.04 parts, retention aid 0.0005 parts, organic particles 0.0003 parts, silica sol 0.003 parts, defoamer 0.0004 parts.

[0045] Preferably, the retention aid is polyacrylamide.

[0046]Preferably, the food packaging base paper is used for packaging food.

[0047] The manufacturing process based on unbleached full bamboo pulp food packaging base paper comprises the following steps:

[0048] a. Pulp preparation: send the natural color pulp of the whole bamboo pulp to the storage tank, and then undergo beating respectively to obtain refined bamboo pulp with a pulp concentration of 4.0% and a beating degree of 40-55°SR;

[0049] b. 0.01 part of aluminum sulfate, 0.018 part o...

Embodiment 3

[0059] Unbleached whole bamboo pulp food packaging base paper, the food packaging base paper includes bamboo pulp and chemical auxiliary materials, and the chemical auxiliary materials include the following components in parts by weight: 0.02 parts of aluminum sulfate, 0.028 parts of rosin gum, talcum powder 0.07 parts, retention aid 0.0006 parts, organic particles 0.0005 parts, silica sol 0.004 parts, defoamer 0.0005 parts.

[0060] Preferably, the retention aid is polyacrylamide.

[0061] Preferably, the food packaging base paper is used to prepare food packaging base paper.

[0062] The manufacturing process based on unbleached full bamboo pulp food packaging base paper comprises the following steps:

[0063] a. Pulp preparation: send the natural color pulp of the whole bamboo pulp to the storage tank, and then undergo beating respectively to obtain refined bamboo pulp with a pulp concentration of 4.0% and a beating degree of 40-55°SR;

[0064] b. 0.02 part of aluminum su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com