Two-way manual input structure for electric cylinder

A manual input, electric cylinder technology, applied in the field of transmission system, can solve the problem of difficult to realize continuous manual input, and achieve the effect of fast manual drive function, small structure space and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to make the purpose, content and advantages of the present invention clearer, the specific embodiments of the present invention are further described in detail.

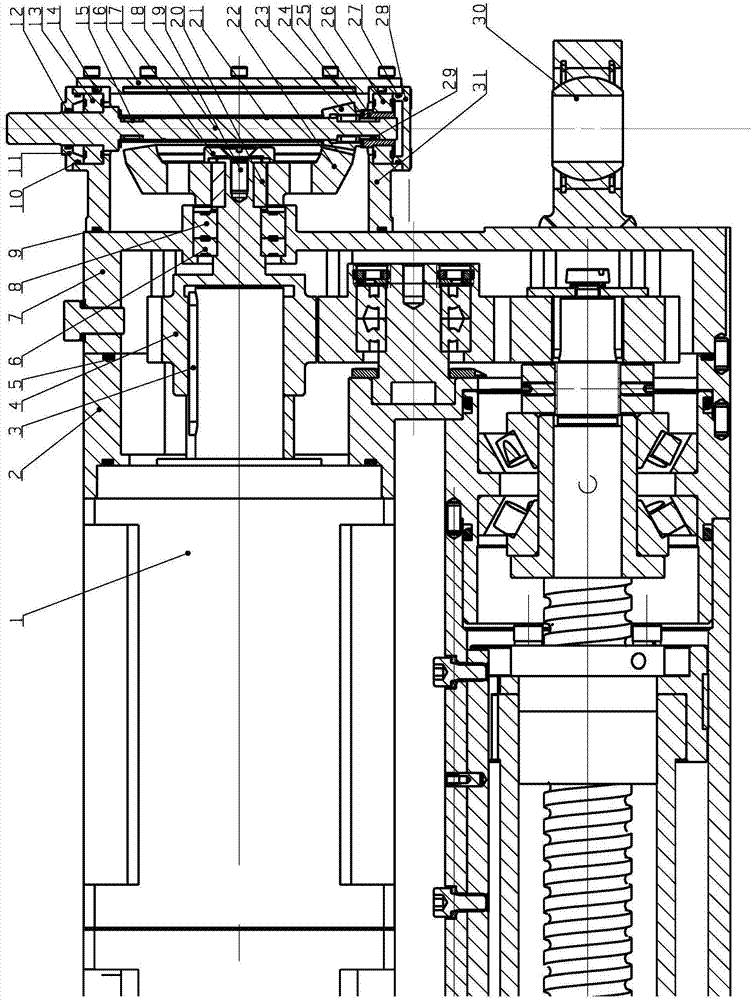

[0009] The present invention provides a bidirectional manual input structure for an electric cylinder, comprising an adapter plate 2, keys 3, 15, 20, 29, gears 4, sealing rings 5, 9, 12, 14, 27, deep groove ball bearings 6, gears Box 7, angular contact bearing 8, O-ring 10, upper bearing pressure plate 11, lower bearing pressure plate 28, upper bearing 13, lower bearing 26, cover plate 16, pressure plate 17, manual input shaft 18, screw 19, sleeve 21, Large bevel gear 22, small bevel gear 23, adjusting washer 24, bearing sleeve 25, electric cylinder rear axle hole 30, manual housing 31;

[0010] The rear end of the reducer (or motor) 1 is connected to the adapter plate 2 by screws, and the rear end of the adapter plate 2 is connected to the gearbox 7 by screws, and is sealed by the sealing ring 5; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com