Flexible assembling type freezer

An assembled and freezer technology, which is applied in the direction of coolers, refrigerated rooms, and isolation of refrigeration devices, etc., can solve the problems of waste of freezer space, achieve the effects of reducing laying, compact design, and avoiding waste of storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

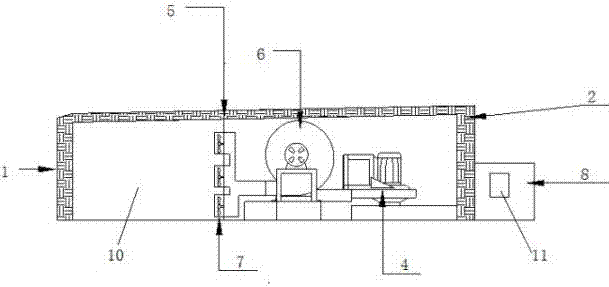

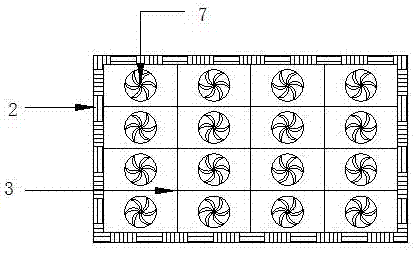

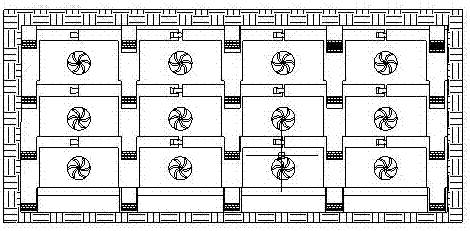

[0017] Embodiment 1: see Figure 1-Figure 4 , a flexible assembled freezer, the flexible assembled freezer includes a freezer, a storage body assembly, a refrigeration assembly, a barrier module, and a computer control room; the refrigeration assembly is located in the storage body assembly; the computer control room is located in The periphery of the storage body assembly; the storage body assembly includes a glass fiber reinforced plastic outer wall 1, a cold storage insulation layer 2 and a barrier module alignment track 3; the glass fiber reinforced plastic outer wall is located at the outer periphery of the cold storage insulation layer; the barrier module is arranged in the freezer. The design structure is simple and clear, the components are closely connected and do not affect each other, the required parts are easy to replace, and it is easy to maintain the product during use in the future; the refrigeration component includes a refrigerator 4, a thermal insulation part...

Embodiment 2

[0018] Example 2: see Figure 1-Figure 4 , as an improvement of the present invention, the computer 11 in the computer control room 8 controls the operation of the refrigerator and the high-efficiency blower. The computer control room is located beside the glass exterior wall; the computer control room controls the operation of the refrigerator and the high-efficiency fan. The computer controls the operation of the refrigerator and the high-efficiency fan, which can accurately control the temperature in the freezer, which is conducive to maintaining a constant temperature in the freezer for a long time. Improve the refrigeration effect and storage time of items.

Embodiment 3

[0019] Embodiment 3: see image 3 , Figure 4 , as an improvement of the present invention, the barrier module 9 includes an aluminum shell 91, a hard foam polyurethane insulation layer 92 and a slider 93; the aluminum shell is covered outside the hard foam polyurethane insulation layer; the slider is fixed at the bottom of the barrier module. The design of the barrier modules and the selected materials provide long-lasting insulation, robustness and durability. Therefore, this product is more suitable for small and medium-sized cold storage enterprises to produce and sell. The design of the barrier module alignment track can quickly align the required joints when two barrier modules are spliced together, speeding up the installation speed and improving production efficiency. Barrier slides are mounted in the barrier module alignment rails and have the same cross-sectional size as the slides contained in the barrier module. The design of the slider can reduce friction wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com