Single air gun salute and tandem body of single air gun salute

A technology of serial body and salute, applied in the field of salute, can solve the problems of environmental pollution, danger, open flames, etc., and achieve the effect of simple overall structure and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

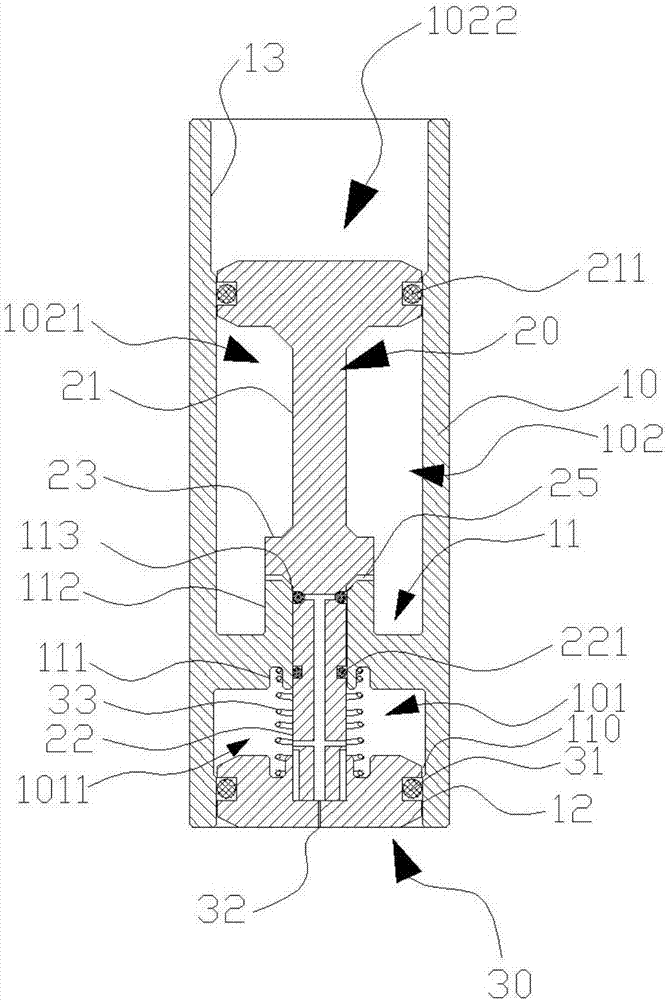

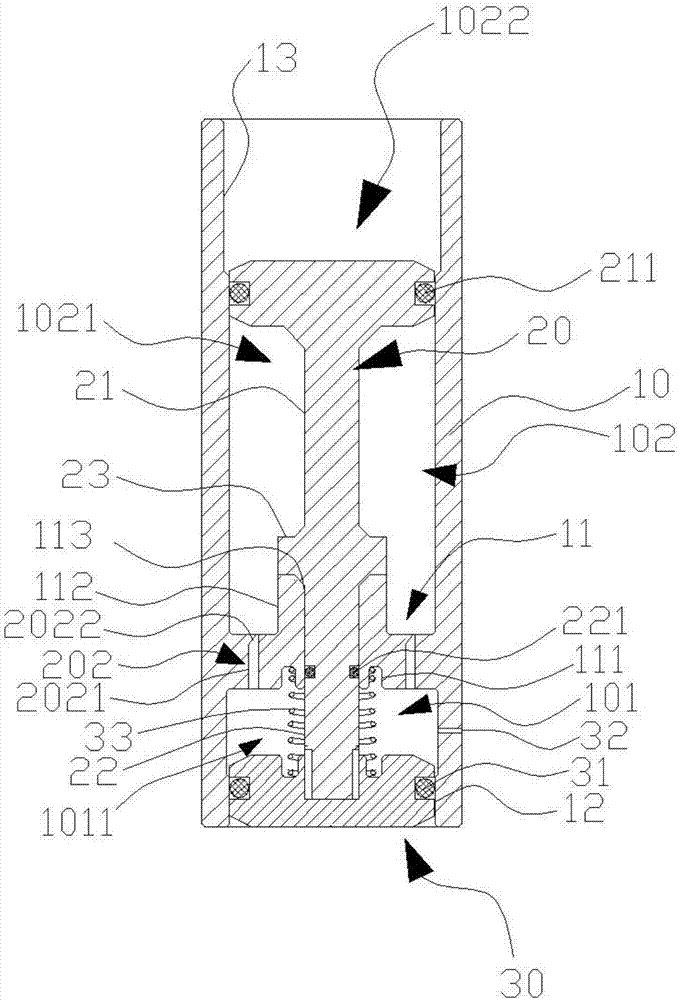

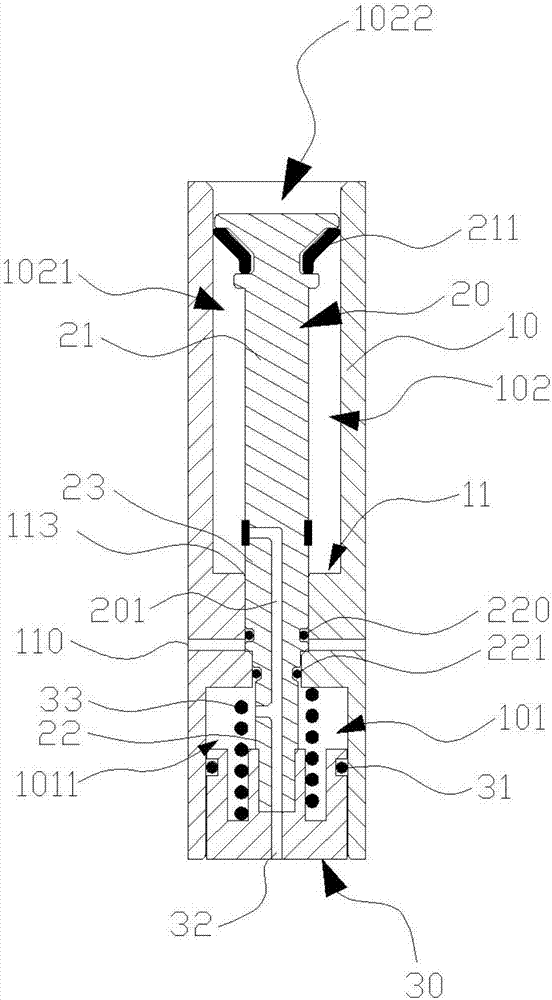

[0025] See figure 1 In this embodiment, the air salute unit includes a gun body 10, a sliding shaft 20 and a gun cover 30. Combined reference Figure 4 The gun body 10 has a hollow structure with open ends. A partition wall 11 is formed in the inner cavity of the gun body 10 near the bottom end to divide the gun body 10 into a first inner cavity section 101 at the bottom end and a first inner cavity section 101 at the top end. The second inner cavity section 102; the center of the partition wall 11 forms an annular groove 111 on the side adjacent to the first inner cavity section 101, the center of the partition wall 11 forms a bearing boss 112 on the side adjacent to the second inner cavity section 102, bearing The center of the boss 112 is formed with an axis hole 113 that penetrates the partition wall 11, and the axis hole 113 communicates with the first inner cavity section 101 and the second cavity section 102; or the center of the partition wall 11 does not need to form th...

Embodiment 2

[0035] See Figure 7 , The air salute series body of the present invention includes an air pump 2001, an air storage device 2002, an overflow valve 2003, a number of one-way valves 2004, a number of solenoid valves 2005, and a number of the air salute units 2006, each air salute unit 2006 Correspondingly connect a one-way valve 2004 and a solenoid valve 2005. In this embodiment, the air pump 2001 can also directly inflate the air salute without using the air storage device 2002, but using the air storage device 2002 can stabilize the air pressure when the air salute unit 2006 is continuously sounding.

[0036] When working, start the air pump 2001 to inflate the gas storage device 2002. The gas storage device 2002 plays a role of storing gas and buffering. The gas storage device 2002 and the overflow valve 2003 are connected through the gas pipe. The overflow valve 2003 plays a safety protection role, and the overflow valve 2003 There is a pressure gauge, which can read the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com