Water lubricating stern bearing adhesion-sliding phenomenon testing system

A test system and tail bearing technology, which is applied in mechanical bearing testing, mechanical component testing, machine/structural component testing, etc., can solve problems such as visual display of non-friction surfaces, and achieve the effect of continuous observation of long strokes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

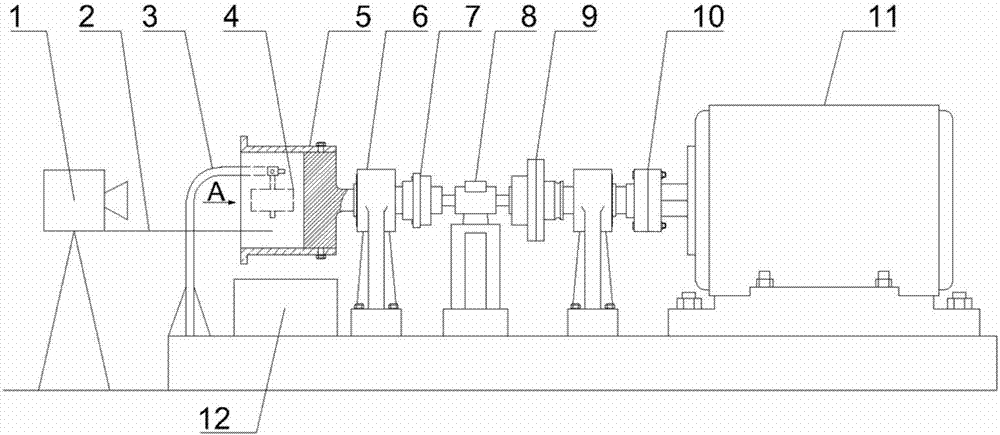

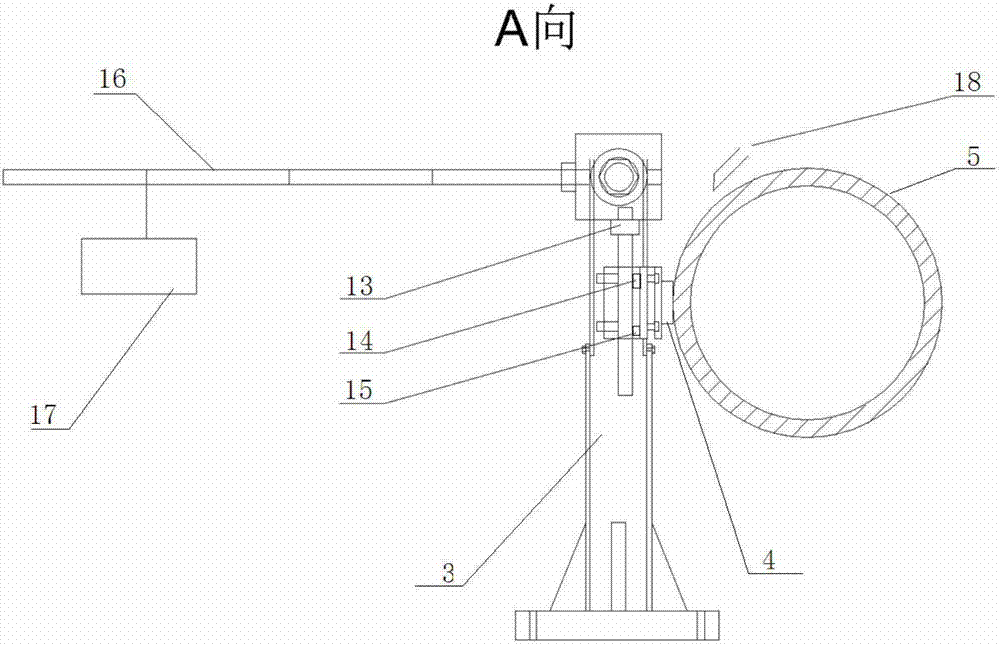

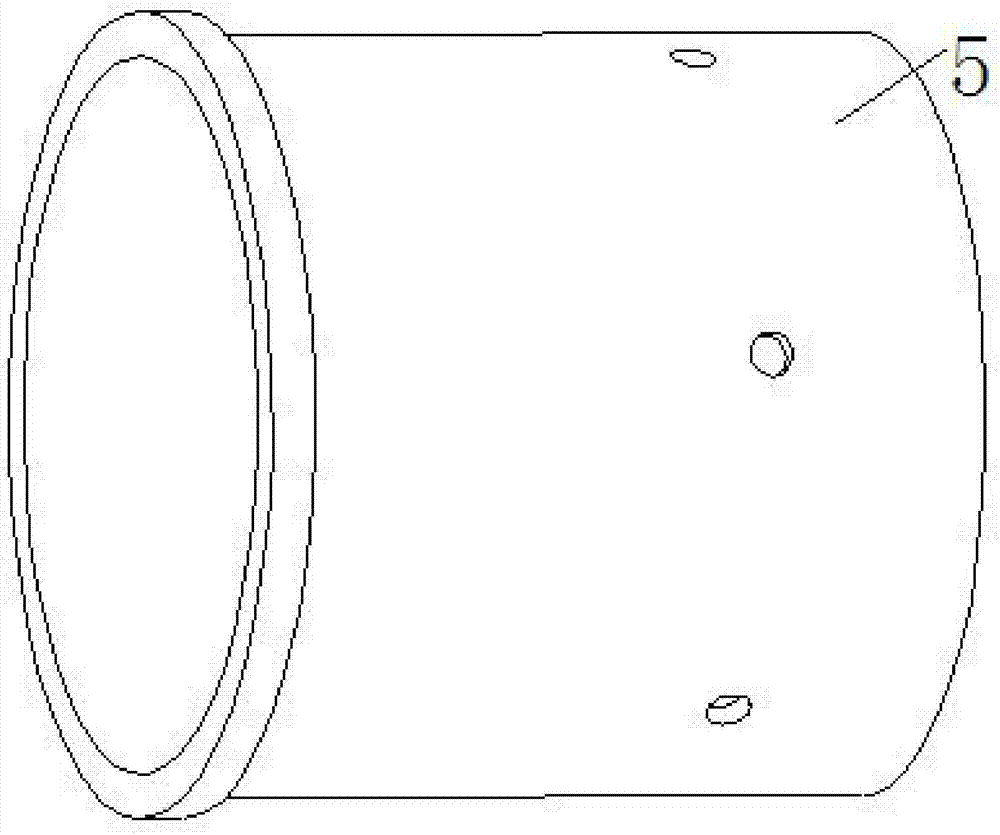

[0039] like figure 1 and figure 2 As shown, a water-lubricated stern bearing stick-slip test system includes a driving unit, a loading unit, a water adding unit, a measuring unit and an image unit. The driving unit includes a motor 11, a coaxial transmission assembly and a glass sleeve 5 connected in sequence, The loading unit includes a bracket 3, a balance lever 16 installed on the bracket 3, and weights 17 and bearing test blocks 4 respectively arranged on both sides of the installation point of the balance lever 16. The outer surface of the glass sleeve 5 contacts the working surface of the bearing test block 4 to form a The friction pair and the water adding unit include a water tank 12 connected in sequence (the water tank 12 is located under the friction pair and can hold lubricating water to complete the cycle), a pump and a water spray pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com