Device and method for testing radial deformation of rubber compression test-piece

A technology of radial deformation and testing device, applied in the direction of measuring device, instrument, etc., can solve the problems of no radial deformation testing device, inconvenient testing, etc., and achieve the effects of simple structure, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

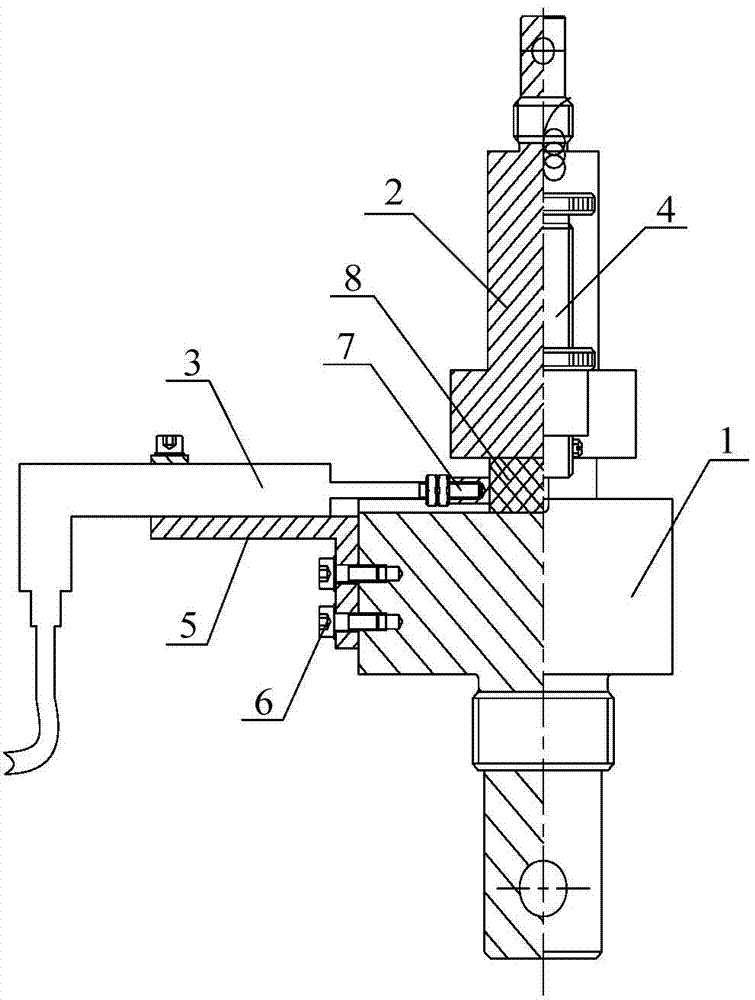

[0028] Such as figure 1 As shown, the rubber compression test piece radial deformation testing device of the present invention mainly consists of a base 1 . In order to facilitate the testing of the radial deformation of the rubber test piece 8 , a radial displacement sensor 3 is also provided on the base 1 . At the same time, the radial displacement sensor 3 is also provided with a contact 7 that is in contact with the rubber test piece 8 during testing. The contact 7 is arranged on the end probe of the radial displacement sensor 3 and is fixed on the radial direction. On the displacement sensor 3 , the contact 7 in this embodiment is fixed on the probe of the radial displacement sensor 3 through screw connection. The installation of the contact 7 can expand the contact range with the radially protruding point of the test piece, that is, when the test piece is axially compressed and radially expanded, the position of the highest point of radial expansion is constantly changi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com