A variable resolution non-scanning streak tube laser imaging system with large field of view and large depth of field

A laser imaging and streak tube technology, which is used in radio wave measurement systems, electromagnetic wave re-radiation, instruments, etc., can solve the problems of reducing the imaging depth of field, reducing the energy of laser echoes, and reducing the detection distance of the lidar system. Increase the vertical range, solve the effect of high spatial resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

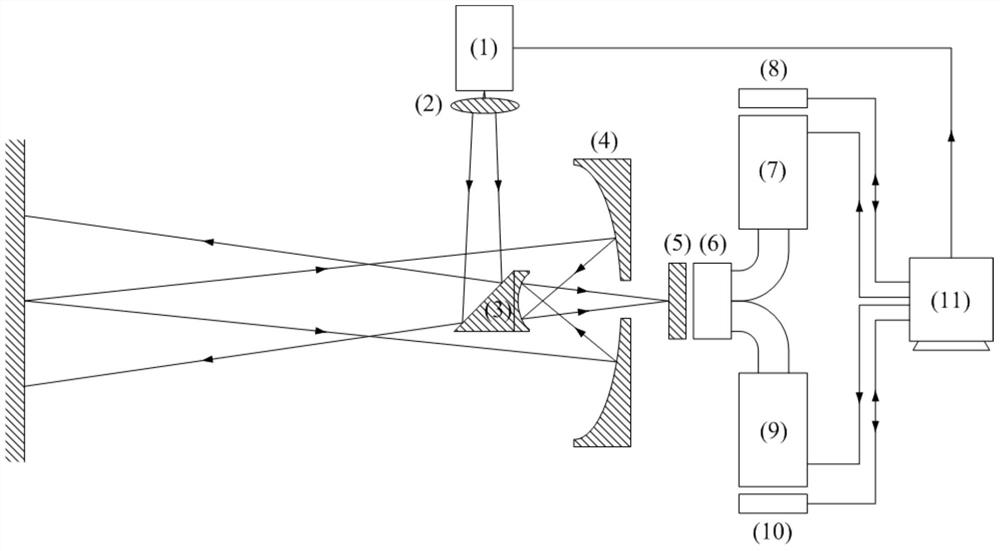

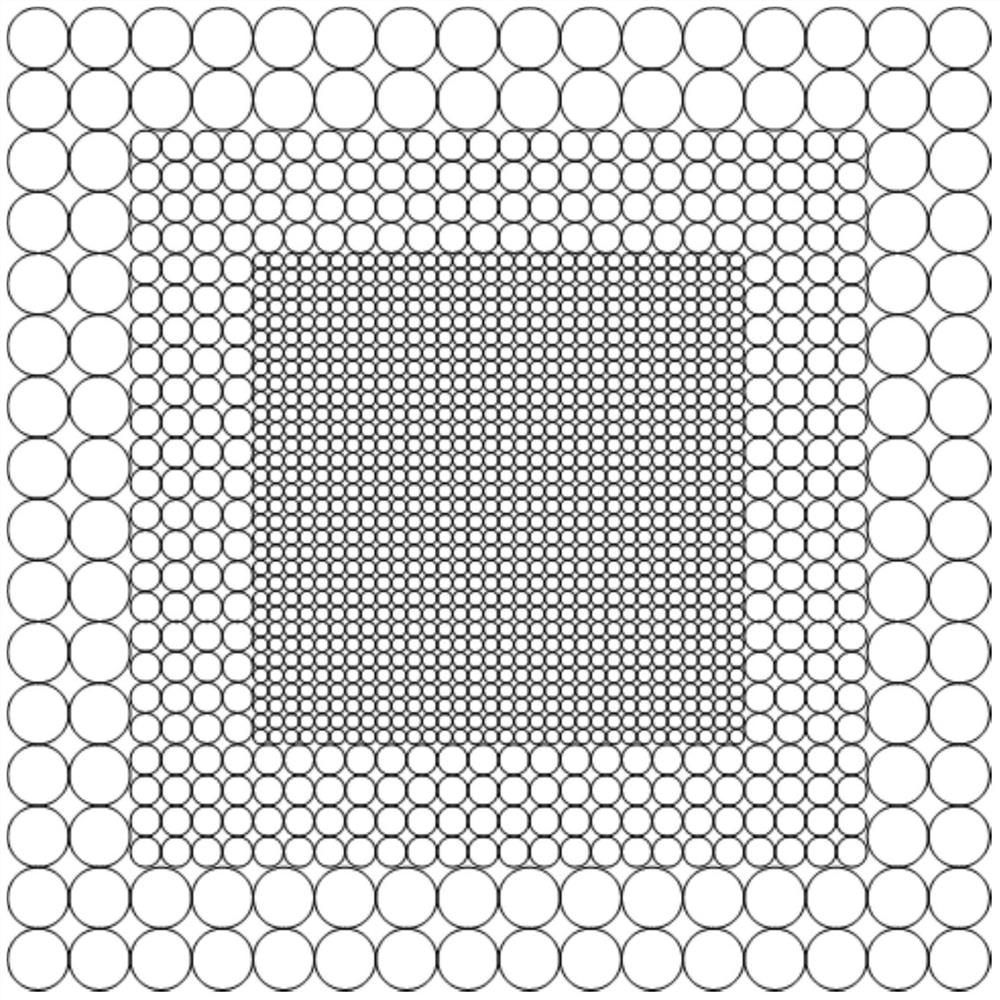

[0024] A variable resolution non-scanning streak tube laser imaging system with large field of view and large depth of field. like figure 1 As shown, the device includes a pulsed laser 1, a beam expanding and shaping optical system 2, a flat mirror 3, a receiving optical system 4, a microlens array 5, an optical fiber image beam 6, a streak tube I7, a CCD camera I8, a streak tube II9, CCD camera II10, control and processing system 11;

[0025] The pulse laser 1 can emit a laser pulse beam with a wavelength of 1064 nm, a pulse width of 5 ns, a repetition frequency of 50 Hz and a small divergence angle after receiving the pulse trigger signal. The laser needs to have good monochromaticity and strong stability. And the characteristics of good heat dissipation performance;

[0026] The beam expanding and shaping optical system 2 has multiple lenses, and the surfaces of the lenses are all coated with an anti-reflection film in the 1064 nm band. The transmitting optical system has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com