Automatic sample injecting device for neutron activation

An automatic sampling and sample technology, applied in the direction of radiation measurement, instruments, etc., can solve the problems of high vibration and noise hazards, low automation, high labor intensity, etc., to reduce labor intensity, improve automation, and reduce on-site Hazardous Effects of Operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

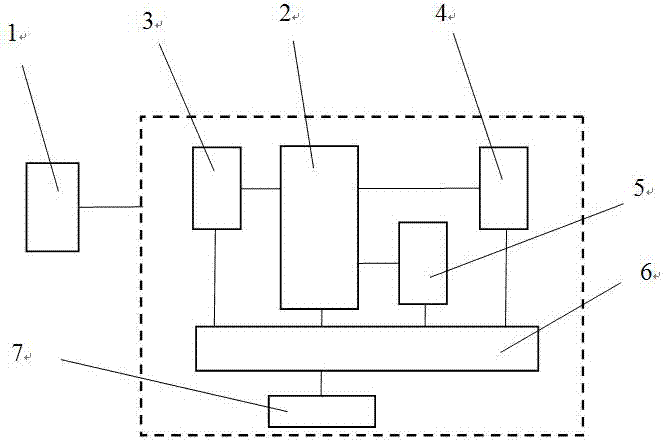

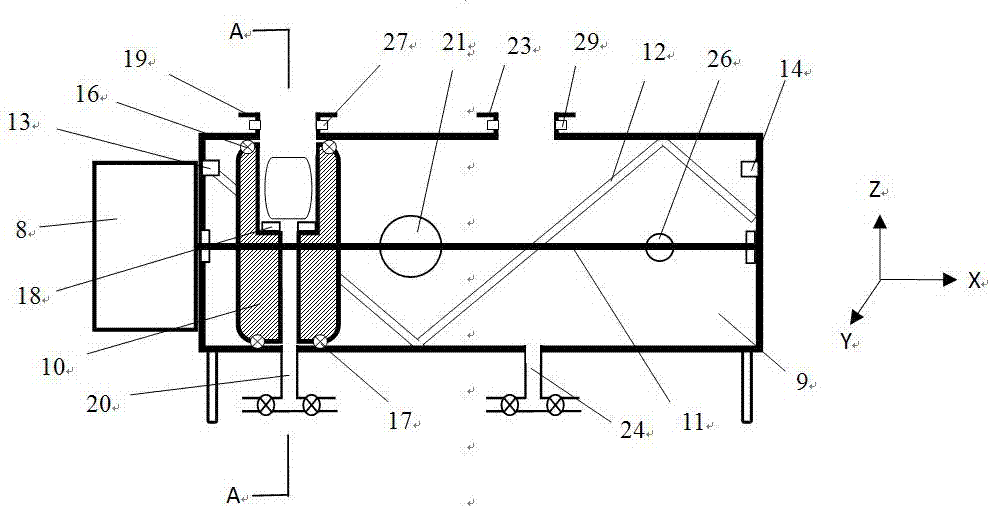

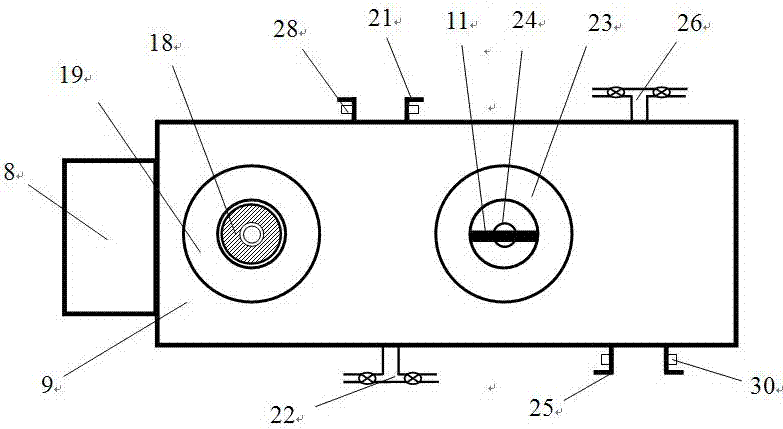

[0029] figure 1It is a block diagram of the overall structure of the sample automatic sampling device for neutron activation of the present invention, figure 2 It is a schematic diagram of the overall structure of the commutator in the present invention, image 3 It is a schematic diagram of the top view structure of the commutator in the present invention, Figure 4 for figure 2 A-A sectional view in, Figure 5 It is a structural schematic diagram of the injector in the present invention. exist Figure 1~Figure 5 Among them, the sample automatic sampling device for neutron activation of the present invention includes a controller 1, a commutator 2, a sampler I3, a sampler II4, a sampler III5, an air tank 6, and an air compressor 7 , the bench, and its connection relationship is that the sample injector I3 and the sample injector III5, the commutator 2 and the sample injector II4, and the gas tank 6 are fixedly arranged on the upper, middle, and bottom layers of the be...

Embodiment 2

[0041] The structure of this embodiment is the same as that of Embodiment 1, the difference is that five flanges are arranged on the cylindrical cylinder 9 and four injectors are connected, and between the longitudinal axes of two adjacent flanges The included angle is 45°, which can transfer more sample boxes to the external irradiator for irradiation.

Embodiment 3

[0043] The structure of this embodiment is the same as that of Embodiment 1, the difference is that six flanges are arranged on the cylindrical cylinder 9 and five sample injectors are connected, so that more sample boxes can be transferred to the external irradiator irradiated inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com