Coating for a potato product for finish-frying, a potato product provided therewith and method therefor

A potato and coating technology, applied in the coating, application, food ingredients and other directions of food, can solve the problems of consumers' unhealthy lifestyle, and achieve the effect of reducing fat content, reducing intake, and good taste and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

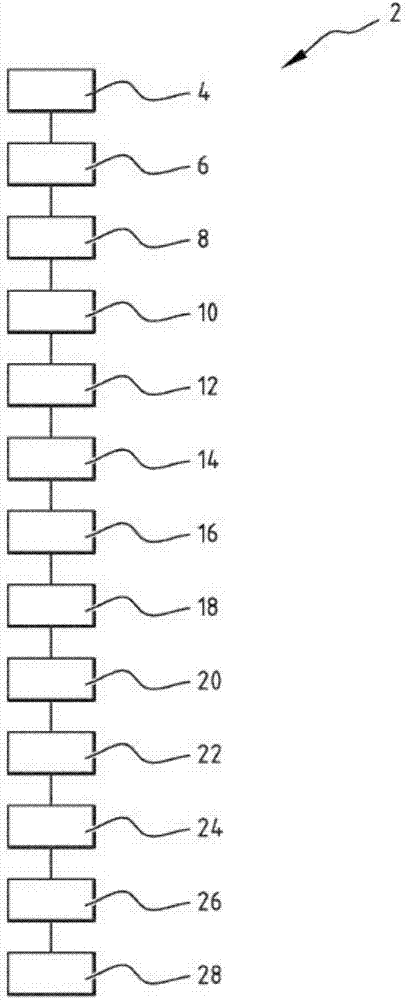

[0067] In process 2( figure 1), step 4 harvests the potatoes, followed by step 6 selection of the potatoes, step 8 optionally storing the potatoes under the best possible storage conditions, avoiding sugar formation as much as possible during storage. Once the potatoes have been transported to the production site, they are preferably subjected to a step 10 of sorting, a step 12 of washing and a step 14 of peeling. After peeling, step 16, the potatoes are cut or processed into desired shapes. After the cutting process, in step 18, a blanching process is usually carried out at a temperature of eg 80°C. Preferably, the product is blow dried, wherein excess water is removed from the article, making the article more suitable for optimal adhesion of the paint. In the presently preferred embodiment, the optional pre-dust removal step 20 is omitted. After step 20, in step 22, the potato product is applied with the desired coating in a coater using, for example, a tub and / or sprayer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com