Method of manufacture of partial or complete dentures and dentures obtained according to this method

A complete denture and denture technology, applied in the manufacture of tools, additive manufacturing, filling teeth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

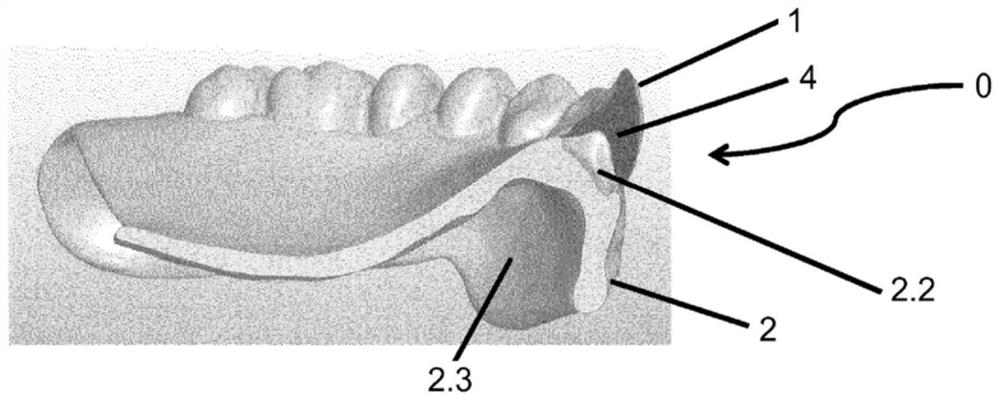

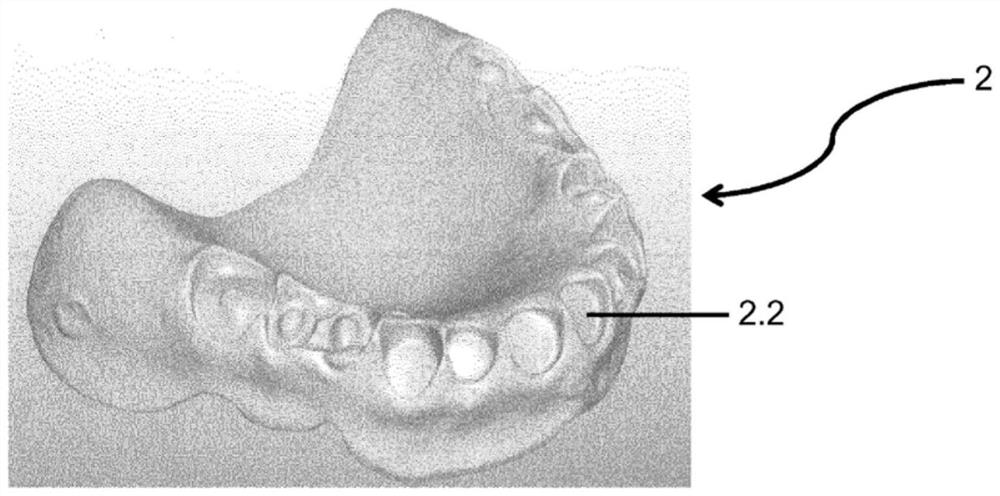

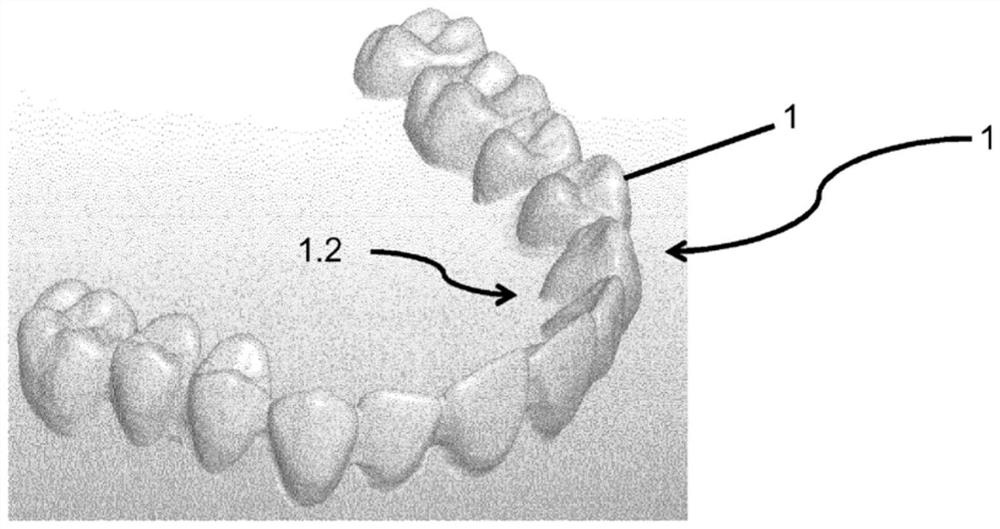

[0122] figure 1 An incisional complete denture 0 obtained from digital data of a virtual model of the surface 0 of the molding of the prosthesis is shown. Subsequently, this data is divided by software (file splitting) in Figure 2a The numerical data of the denture base (base) shown as denture base 2 in and in Figure 2b Numerical data for denture 1 shown in Figure 1 as the surface shell of the denture. At the neck (underside not visible) there is the neck area 1.2 of the denture. figure 1 The gingival surface 2.3 of the denture base (on the gingiva) is further shown in .

[0123] additionally, in Figure 2a The alveolar area 2.2 is shown in the alveolar area, in which a virtual model of at least one denture 1 or a plurality of dentures 1 and a virtual model of the denture base 2 are divided, or alternatively in this area there is a closed Alveolar surface 2.2. In the region 2.2 the cervical region 1.2 of the denture is embedded, in particular by the aggregation of exce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com