Rapid assembly system

An assembly system, fast technology, used in metal processing equipment, metal processing machine parts, clamps, etc., can solve assembly problems, no temperature stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

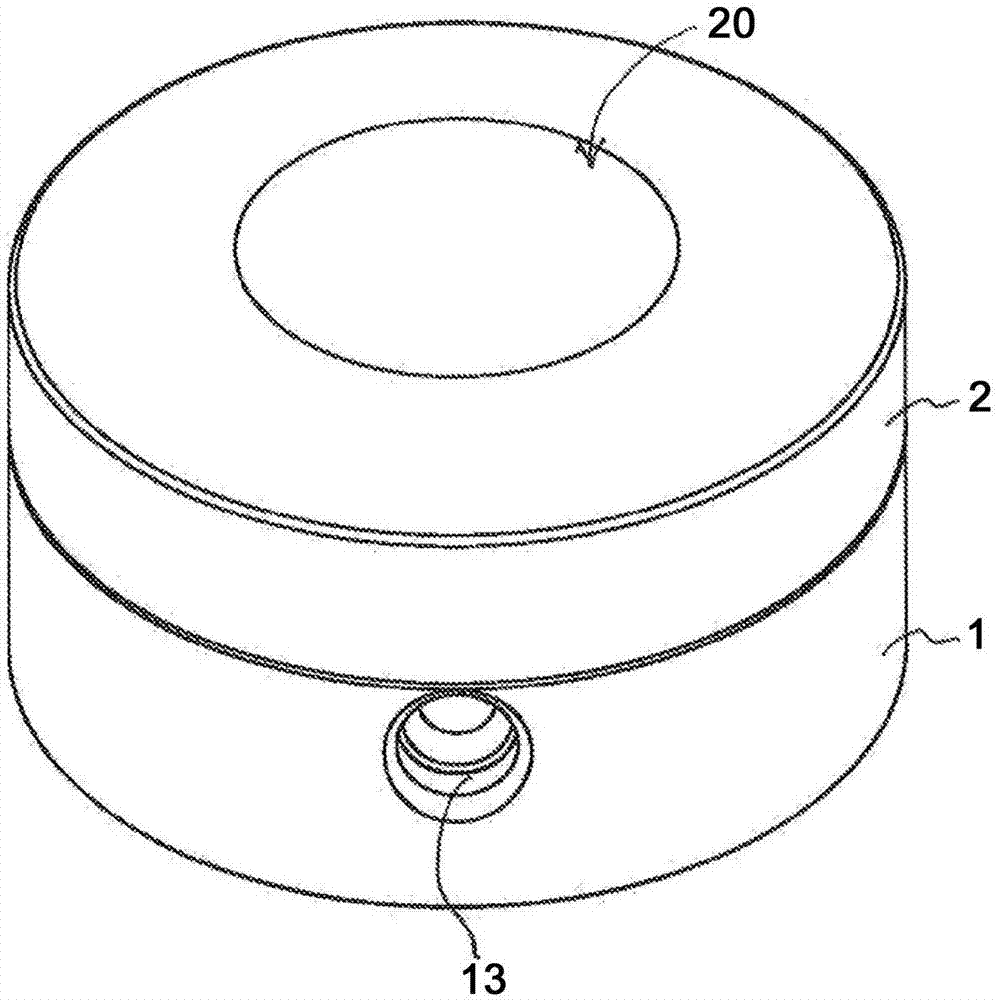

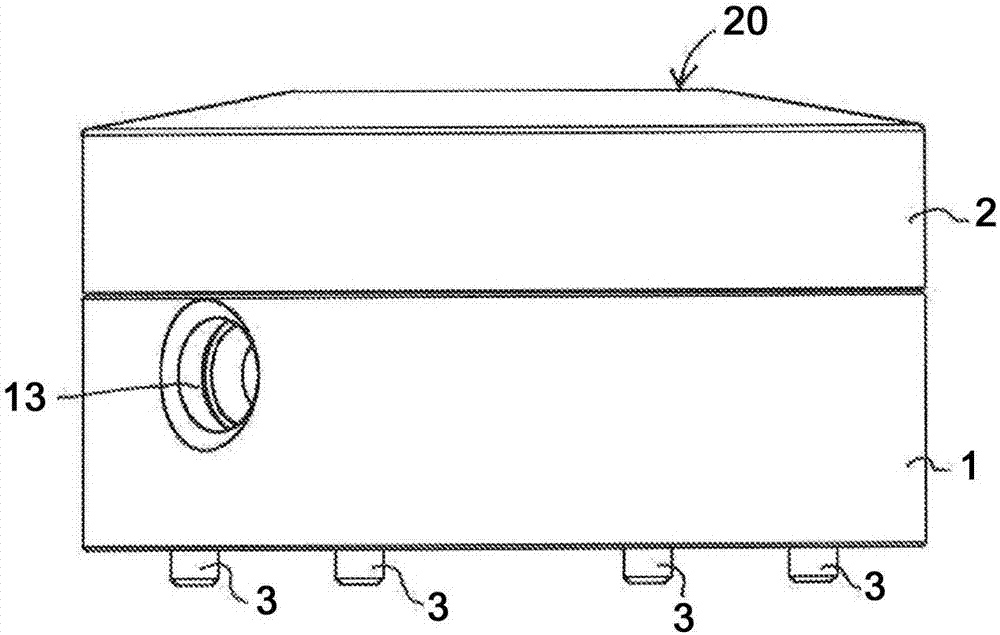

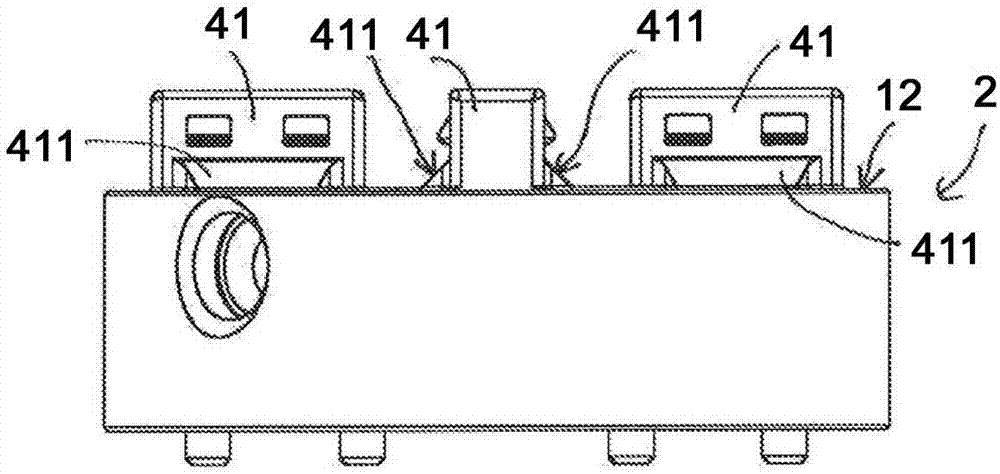

[0035] According to the first embodiment of the present invention, in figure 1 and figure 2 A quick assembly system comprising a mount 1 and a plate 2 removably fitted on the mount 1 is shown in . They have a cylindrical shape of substantially the same diameter. The upper surface 20 of the plate 2 is intended to receive a part (not shown) to be machined. The mount 1 is designed to be assembled on the table or spindle of a machine tool (not shown, such as a machining center or lathe). The screw 3 and the mounting 1 are shown and are designed to be attached to a machine tool.

[0036]The assembly system comprises four connection devices 4 between the plate 2 and the mount 1 . Each connection device 4 comprises a tooth portion 41 attached to the mount 1 and a groove portion 42 provided in the plate 2 . Each tooth 41 comprises a pair of tooth engaging surfaces 411 arranged in a V shape, the theoretical intersection section of which extends in the direction of the tooth. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com