Excavator Arm Having Rotation Device

A technology for rotating devices and excavators, which is applied in the direction of mechanically driven excavators/dredgers, transmissions, gear transmissions, etc., which can solve the problems of low efficiency of excavation operations, high time consumption of excavation operations, and inability to simply carry out excavation operations and other issues to achieve the effect of effective rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Hereinafter, preferred embodiments of an arm for an excavator having a swivel device according to the present invention will be described in detail with reference to the drawings.

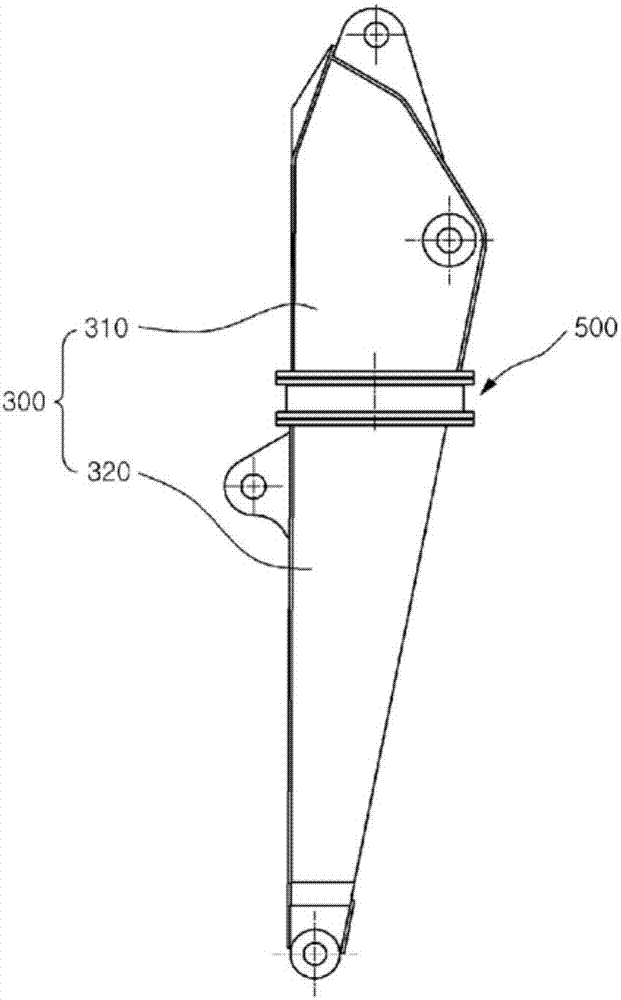

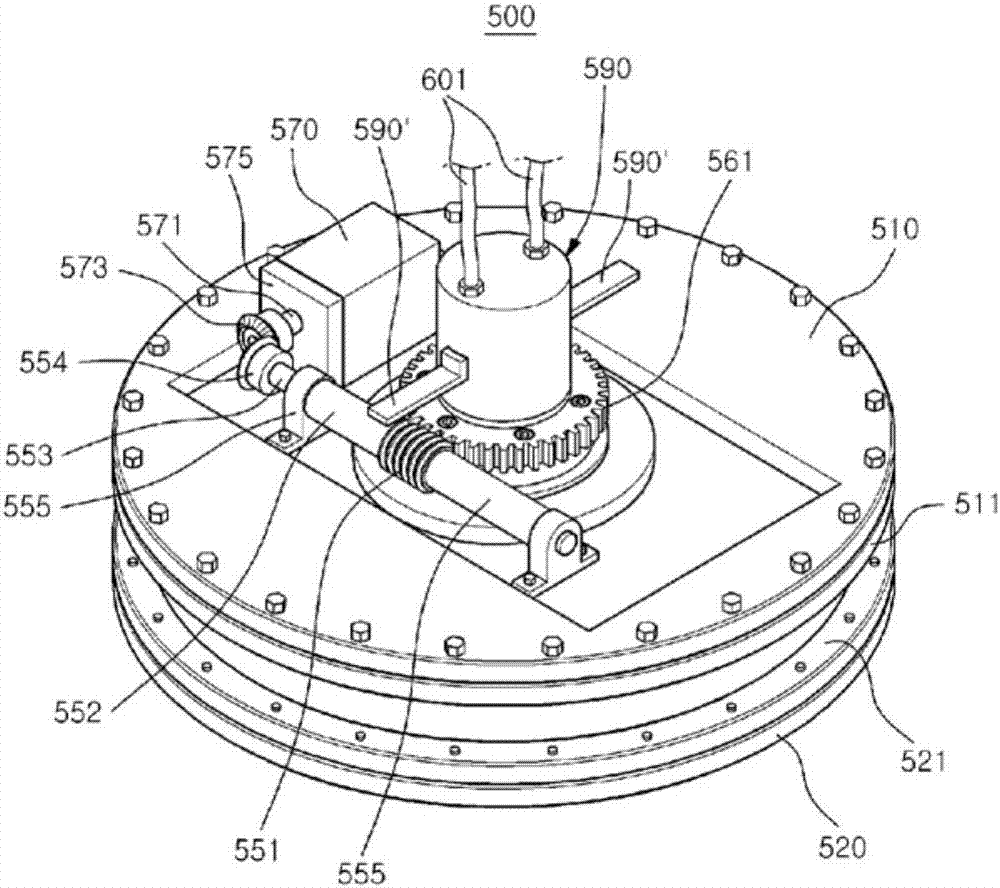

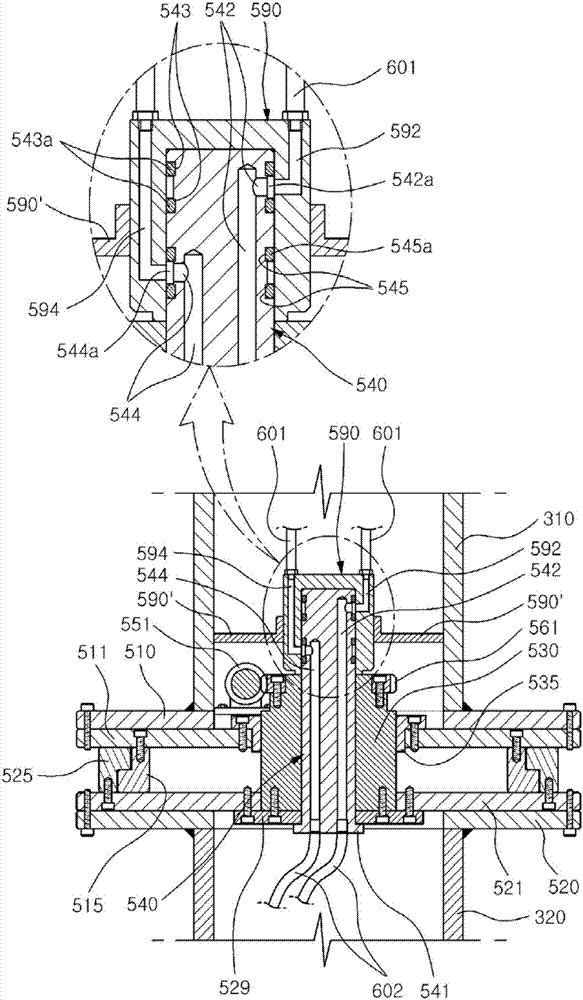

[0069] figure 1 In order to show the front structural view of the arm of the excavator with the rotating device of the present invention, figure 2 It is a three-dimensional structural view showing a rotating device as a main part of an arm for an excavator having a rotating device according to the present invention, image 3 In order to show the sectional structure diagram of the rotation device which is the main part of the arm of the excavator with the rotation device of the present invention, Figure 4 It is a top structural view showing a swivel device as a main part of an arm for an excavator having a swivel device according to the present invention.

[0070] Figure 5 and 6 It is a use state diagram showing the state in which the lower arm of the arm for an excavator having a rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com