Backpack forklift

A knapsack, forklift technology, applied in the direction of lifting devices, can solve the problems of poor space utilization, can not pass the speed bump, high energy consumption, achieve the effect of good passability, flexible control, and reduce the overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

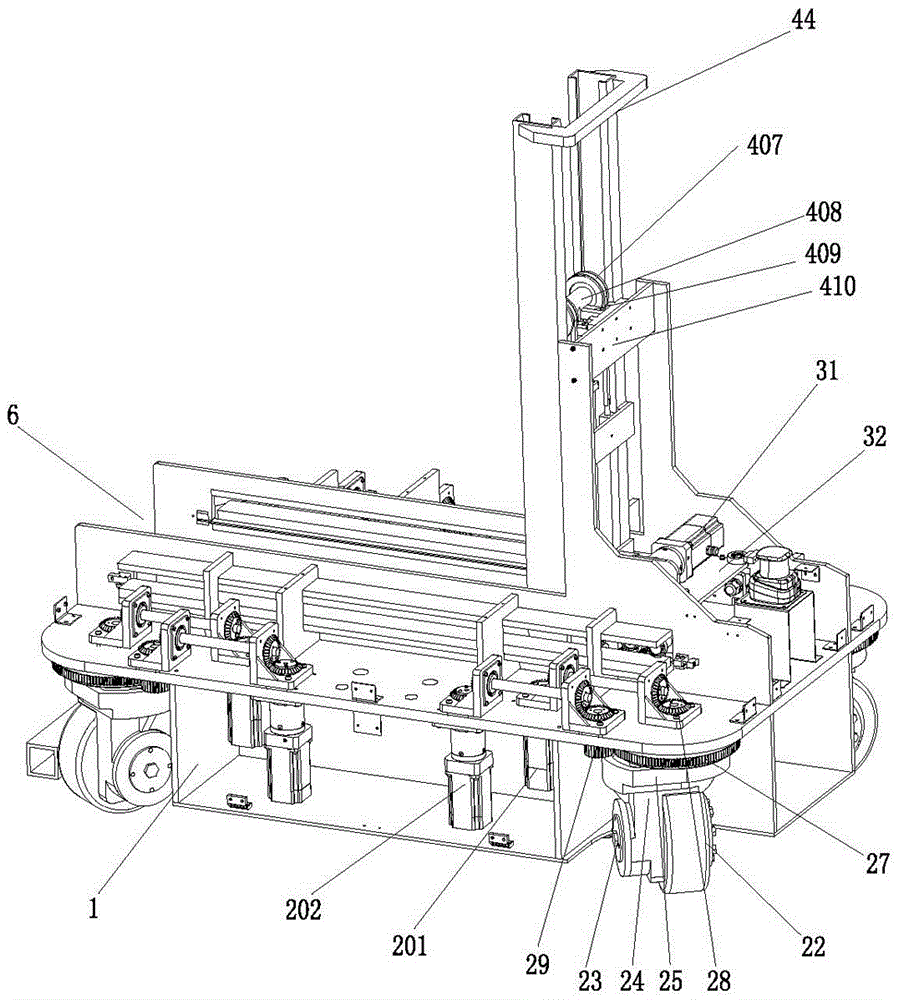

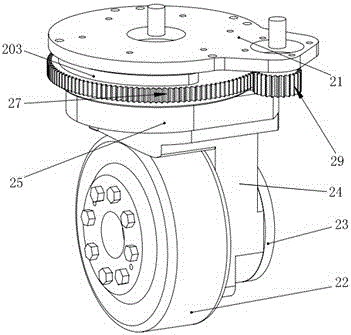

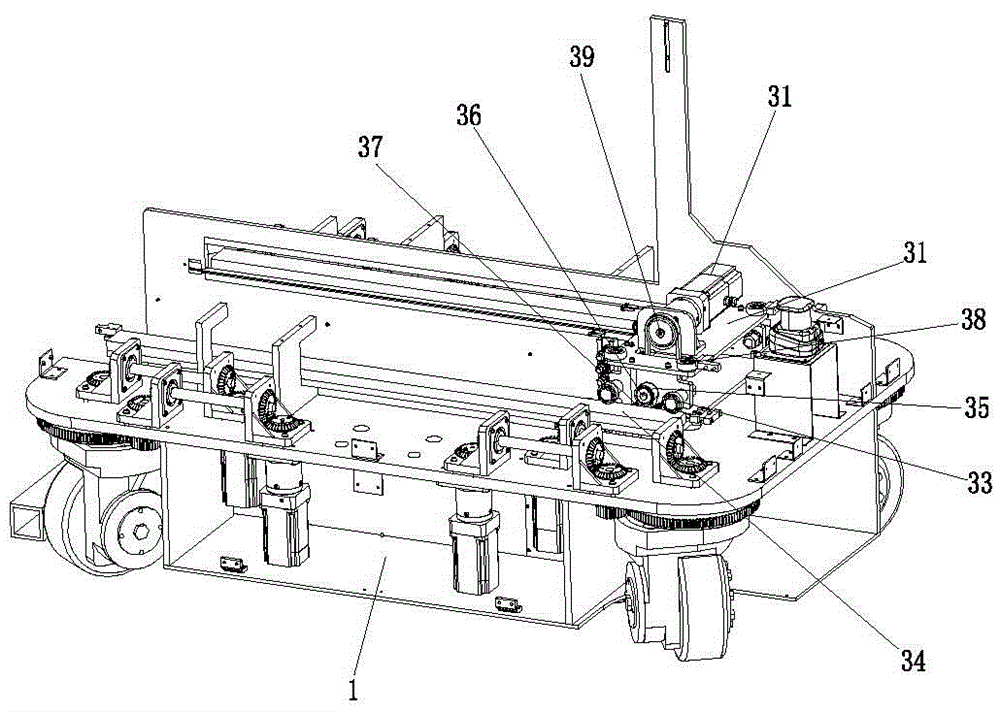

[0022] as attached figure 1 As shown, the present invention discloses a knapsack forklift, which includes a vehicle frame, a running device is installed on the bottom surface of the vehicle frame 1, a pushing device and an electric control system are installed in the vehicle frame 1, and a lifting device is installed on the vehicle frame 1. device, the lifting device is connected with the pushing device, the electric control system is respectively connected with the traveling device, the pushing device and the lifting device, the frame 1 is provided with a sliding groove 6, and the pushing device and the lifting device are both arranged in the sliding groove . The pushing device moves back and forth a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com