DC bus voltage control brushless motor commutation method

A brushless DC motor and DC bus voltage technology, applied in the direction of torque ripple control, can solve the problems of inability to suppress commutation torque ripple and limit the application range, and achieve the effect of improving stability and simplifying design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

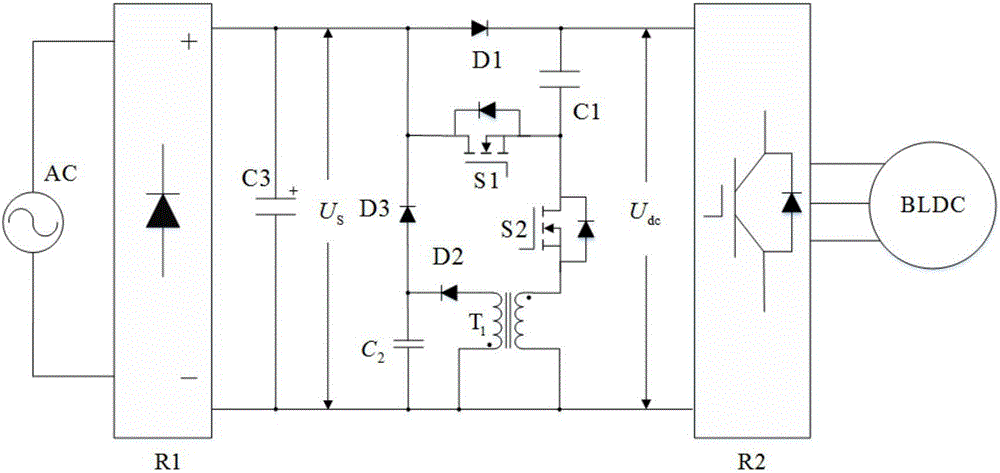

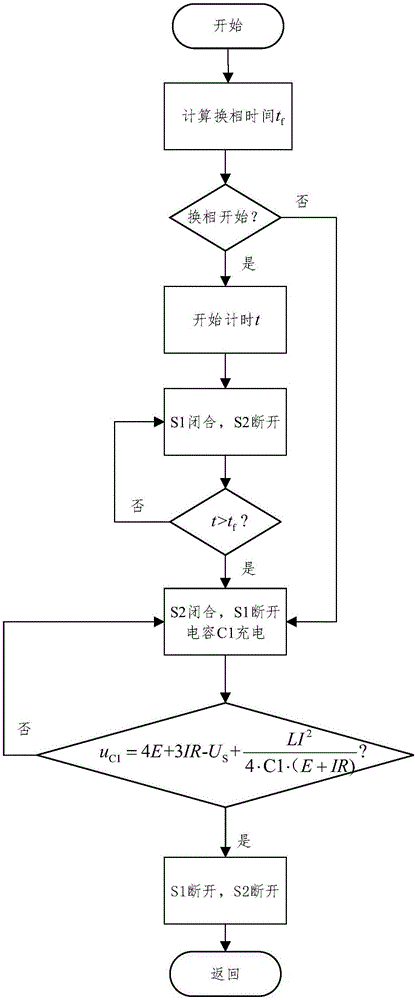

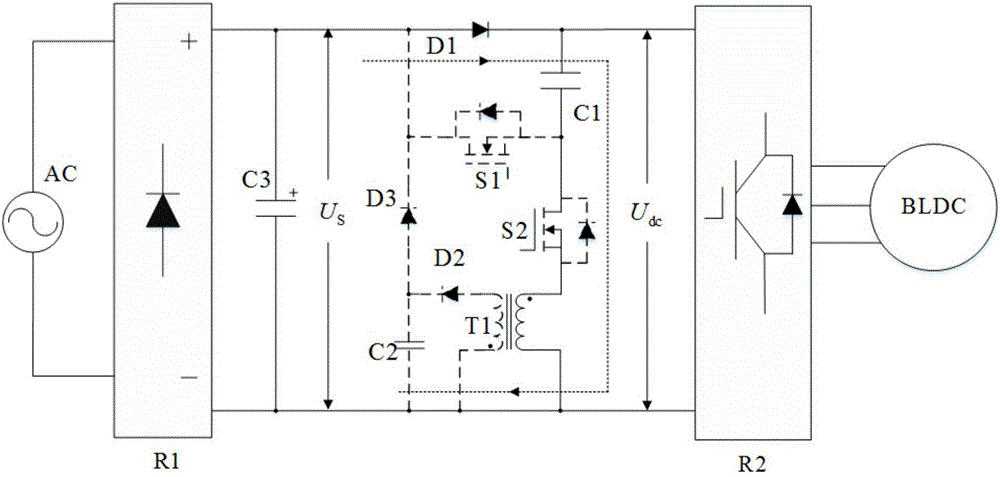

[0032] The present invention will be further described below in conjunction with accompanying drawing:

[0033] The formula of the present invention is used above However, no specific analysis has been made, and the calculation aspects of the formula of the present invention will be deduced in detail below.

[0034] Take the motor A-C phase commutation to B-C phase as an example to analyze. The voltage equation of the three-phase winding in the commutation phase is as follows:

[0035]

[0036]

[0037]

[0038] Among them, u A , u B , u C is A, B, C phase terminal voltage, i A i B i C is A, B, C phase current, e A 、e B 、e C is the opposite electromotive force of A, B, and C, R is the winding resistance, L is the winding inductance, u N is the motor midpoint voltage, U S is the supply voltage.

[0039] Assuming that the back electromotive force of the motor winding has an ideal trapezoidal wave with an electrical angle of 120°, then the opposite electrom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com