Process for manufacturing leather shoes

A preparation process and a technology for leather shoes, which are applied in the directions of footwear, bonding shoe parts, shoe-making machinery, etc., can solve problems such as low drying efficiency, and achieve the effects of improving drying efficiency, improving convenience, and reducing irritating odors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

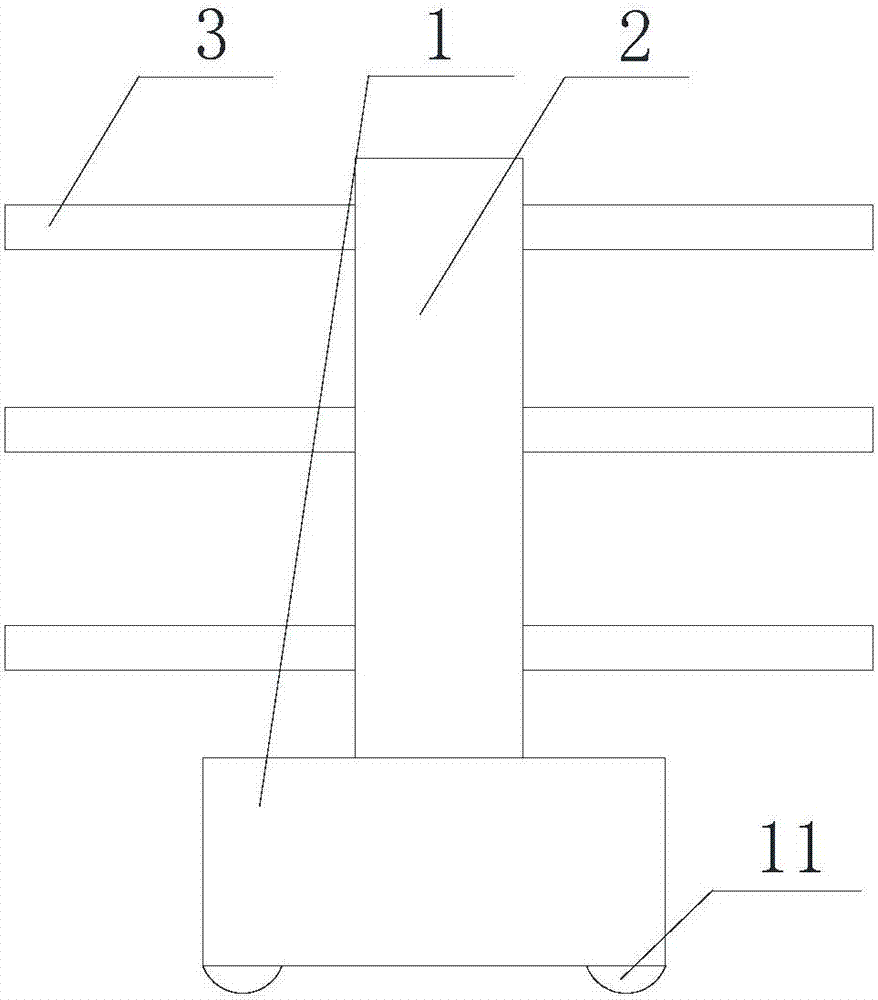

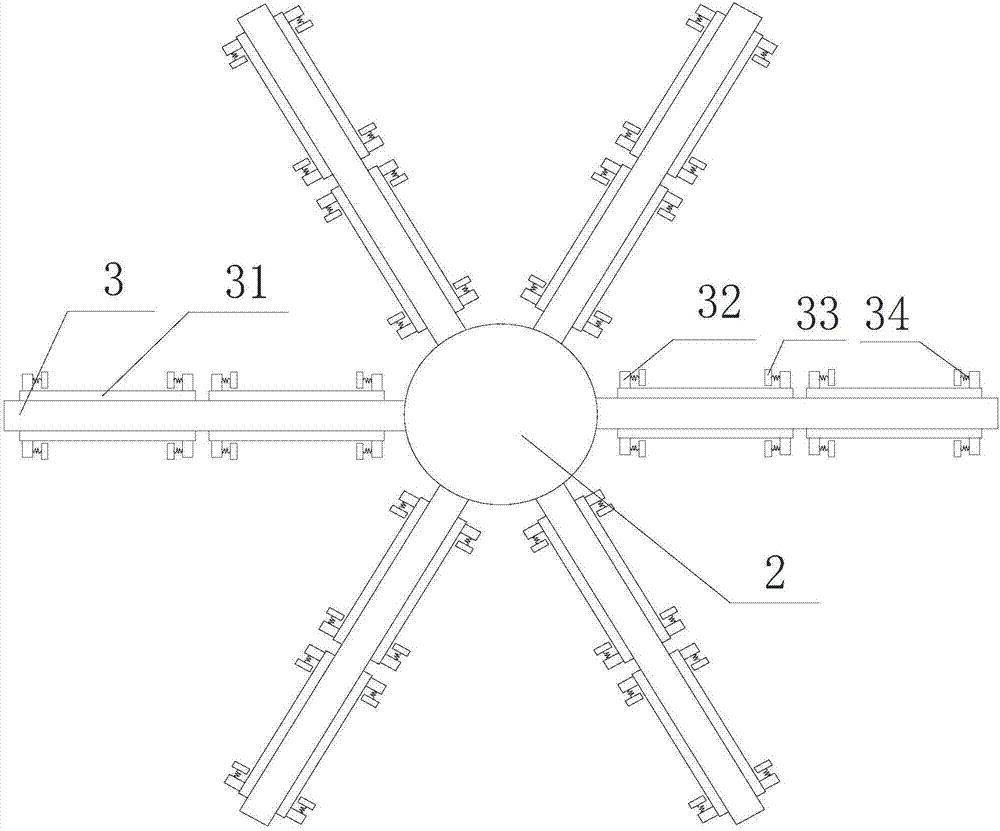

[0036] like figure 1 , figure 2 Shown, a kind of leather shoes preparation technology comprises the following steps:

[0037] 1) Fabric pretreatment: clean the fabric and dry it to deodorize;

[0038] 2), the fabric processed in step 1) is cut into shoe uppers according to the template;

[0039] 3), sticking the vamp obtained in step 2) with the inner village to make a shoe upper;

[0040] 4), the raw materials are made into soles according to the model;

[0041] 5) Sew the upper and sole together;

[0042] 6), spray paint on the upper;

[0043] 7) Drying: Put the leather shoes on the shoe rack and send them to the drying room for drying treatment. The shoe rack includes a base 1, a motor is arranged inside the base 1, and a rotating shaft 2 is connected to the power output end of the motor. , the rotating shaft 2 is provided with a plurality of placing plates 3, the placing plate 3 is provided with a fixed plate 31, and the fixed plate 31 is provided with a clamping me...

Embodiment 2

[0045] like figure 1 , figure 2 As shown, this embodiment is based on Embodiments 1 and 2. A manufacturing process for leather shoes according to claim 1, characterized in that, the bottom of the rotating shaft base 1 is provided with rollers 11 .

[0046] 3. A leather shoe manufacturing process according to claim 1, characterized in that the rotating shaft 2 and the placing plate 3 are made of hard aluminum alloy.

Embodiment 3

[0048] The deodorization in step 1) adopts deodorant, and described deodorant is made up of following components by weight:

[0049] 25 parts by weight of ginger, 25 parts by weight of tangerine peel, 20 parts by weight of orange peel, 15 parts by weight of carbon powder, 28 parts by weight of green tea, 12 parts by weight of honeysuckle, 15 parts by weight of mint, and 8 parts by weight of Angelica dahurica.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com