Station switching device of full-automatic intelligent milk powder mixing machine

A technology for switching devices and milk machines, which is applied in beverage preparation devices, kitchen utensils, household appliances, etc. It can solve problems such as the degree of automation of milk machines to be improved, the workload of the daytime, and the impact on sleep quality, so as to avoid cross-infection, The effect of reducing physical and mental fatigue and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

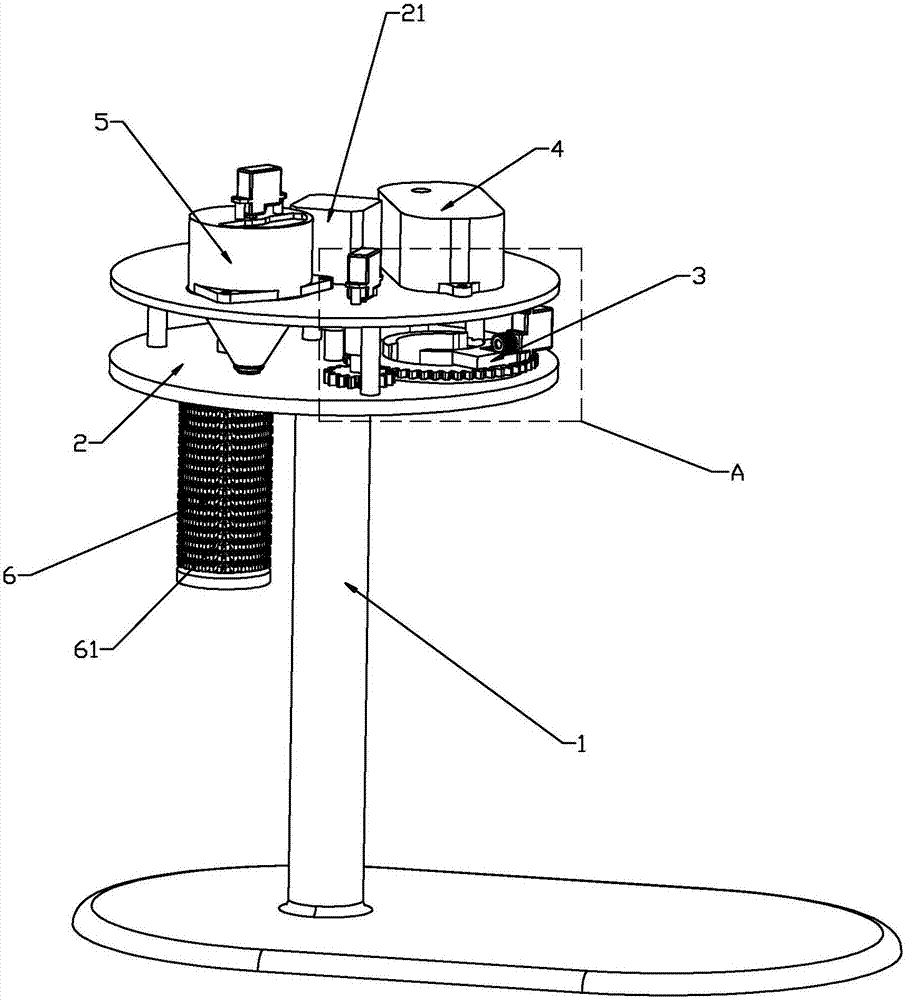

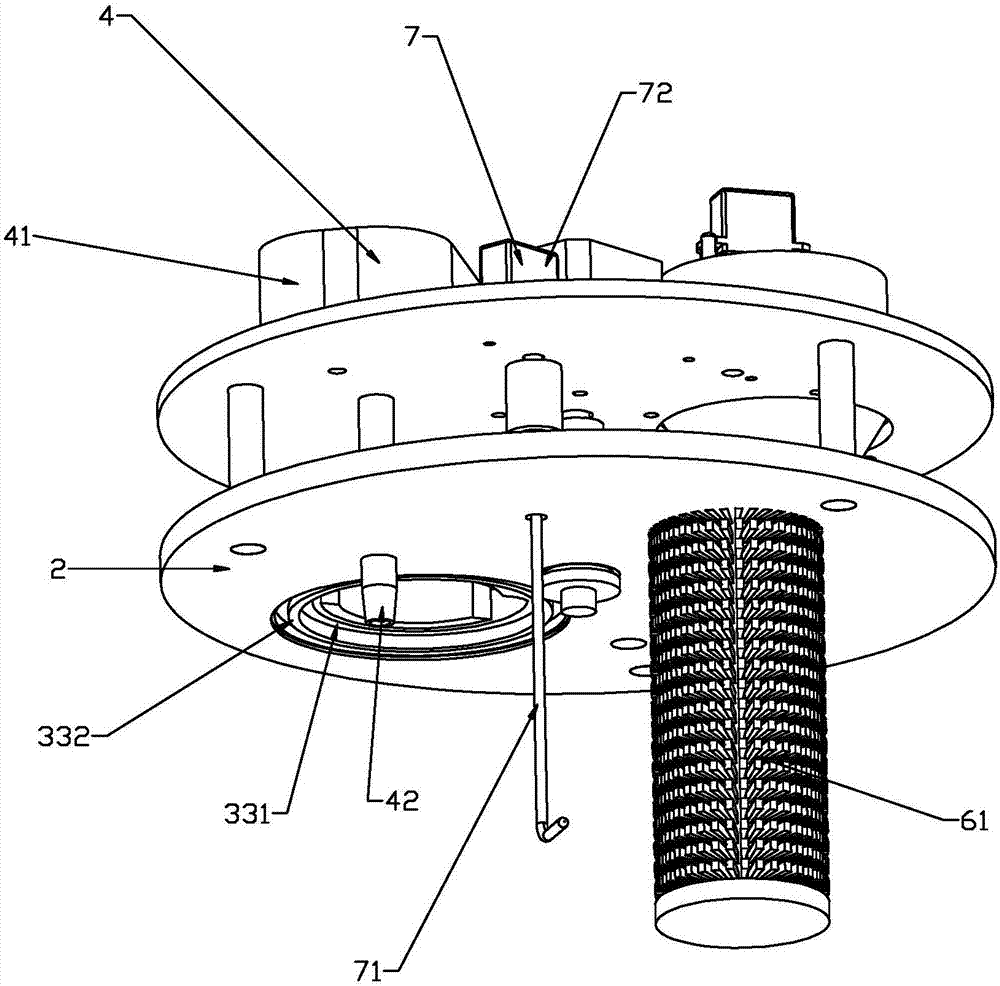

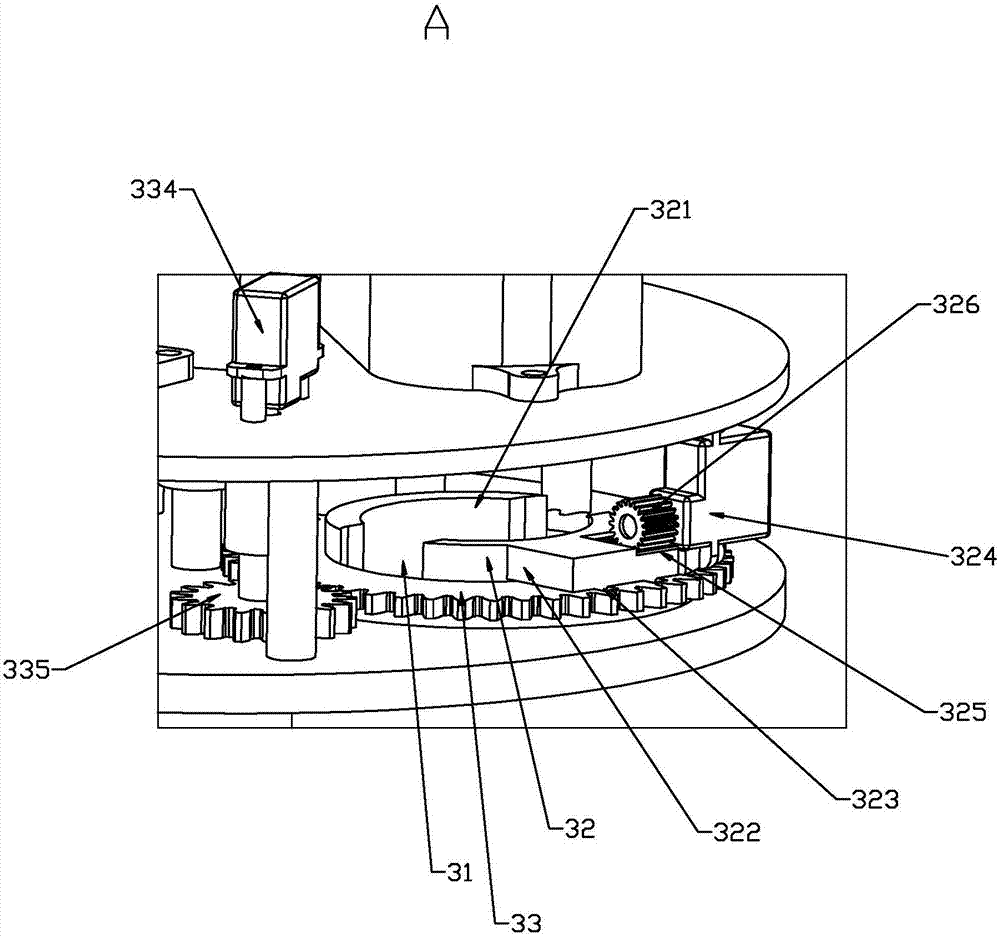

[0027] Such as figure 1 — Figure 4 As shown, the present invention discloses a station switching device for a fully automatic intelligent milk maker, which includes a frame 1, on which a switching turntable 2 and a rotating mechanism 21 are arranged, and the switching turntable 2 is arranged on the frame 1 for horizontal rotation. , the switching turntable 2 is provided with a screw cap mechanism 3 for opening or closing the feeding bottle cap along the direction of rotation, a flushing device 4 for flushing water into the feeding bottle, a milk powder placing device for pouring milk powder into the feeding bottle, and a cleaning device 6 for cleaning the inner wall of the feeding bottle And the stirring device 7 that milk powder is mixed with water, the rotating mechanism 21 drives the switching dial 2 to rotate, so that the capping mechanism 3, the flushing device 4, the milk powder placement device 5, the cleaning device 6 and the stirring device 7 are respectively connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com