Falling film crystallizer

A technology of falling film crystallization and film forming tubes, which is applied in the field of falling film crystallizers, can solve problems such as material crystallization efficiency, quality impact, and installation level deviation of falling film crystallizers, and achieve simple structure, reasonable design, and uniform overflow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] specific implementation plan

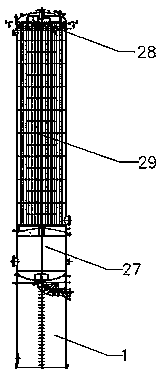

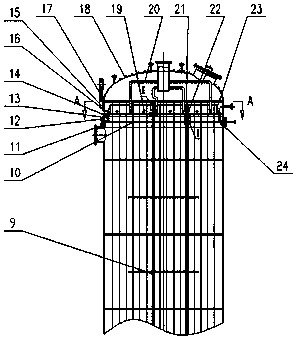

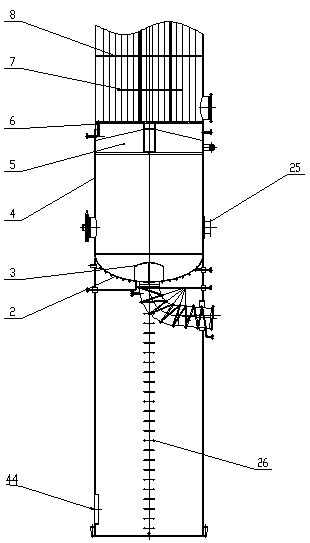

[0027] Refer to attached Figure 1-10 , a falling film crystallizer, which includes a skirt 01, an equipment body 27, a shell-and-tube heat exchanger 29, a liquid distribution system 28, and a vortex breaker 3; the skirt 01 is fixed at the bottom of the equipment body 27, supporting the equipment Body 27; the device body 27 includes an upper head 18, a lower head 2, and a cylinder body 4. The upper head 18 is arranged at the top of the cylinder body 4, and a group of flanges 11 pass between the upper head 18 and the cylinder body 4. , flange 12, flange 11 and flange 12 are connected by bolts 24, and the upper head 18 is respectively provided with a material inlet 30 and an exhaust port 31, and the lower head 2 is arranged at the bottom of the cylinder 4, And the lower head 2 is provided with a material outlet 30; the upper head 18 is provided with a liquid distribution system 28, and the liquid distribution system 28 is fixed on the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com