Cutting and edge polishing integrated machine for ceramic

An all-in-one machine and edging technology, applied in machine tools suitable for grinding workpiece edges, parts of grinding machine tools, grinding machines, etc., can solve the problems of inoperable cutting and edge detection, difficult mechanical operation, etc. Operation and the effect of improving safety and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

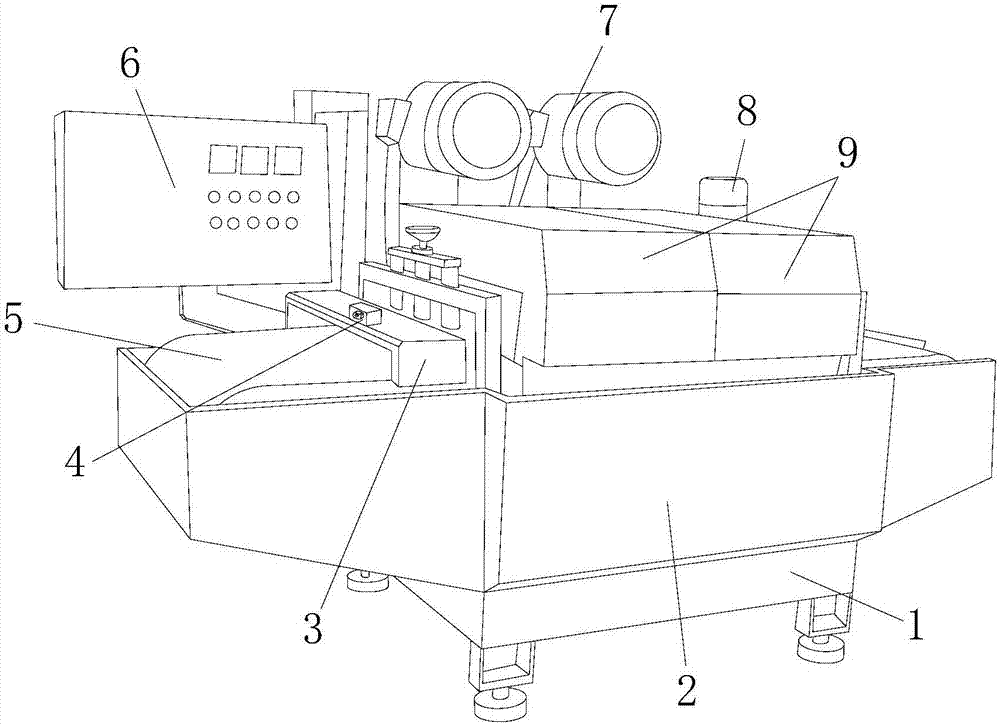

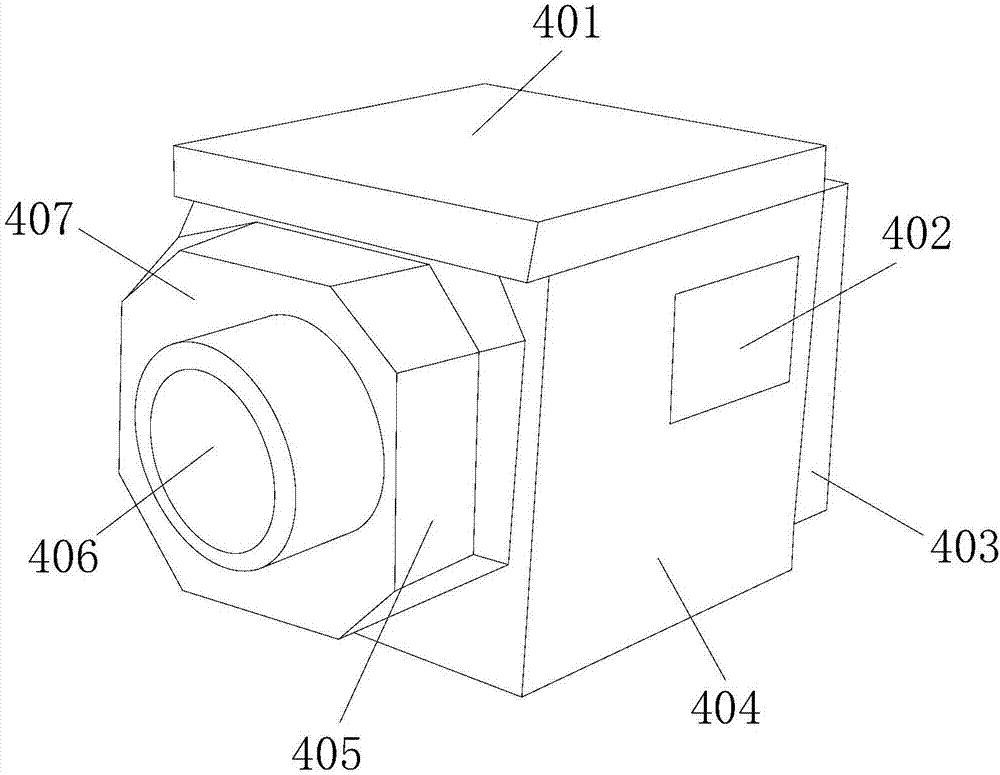

[0019] see Figure 1-Figure 2 , the present invention provides a technical solution: a ceramic cutting and edging integrated machine, its structure includes a bottom plate 1, a box body 2, a feed port 3, an infrared detector 4, a conveyor belt 5, a numerical control box 6, a transmission 7, a motor 8. Cutting the main body 9 of the edger. The box body 2 is a trapezoidal structure whose upper and lower sides are parallel and rectangular. The top surface and the bottom surface of the conveyor belt 5 are flexibly connected by a clearance fit. The box body 2 has a height of 40cm. The cutting The cross-section of the edger main body 9 is a right-angled trapezoid with a right angle on one side, the bottom surface is set at the center of the top surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com