Vacuum pumping tire segmental mold

A tire active mould, vacuum pumping technology, applied to tires, household appliances, other household appliances, etc., can solve the problem that the vacuum degree inside the mold cannot meet the use requirements, reduce the sealing effect of the base and the guide ring, and enlarge the gap between the guide ring and the base and other problems, to achieve the effect of easy filling of dead corners of molds, reduction of material costs, and beautiful appearance of tires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 Vacuum tire flexible mold

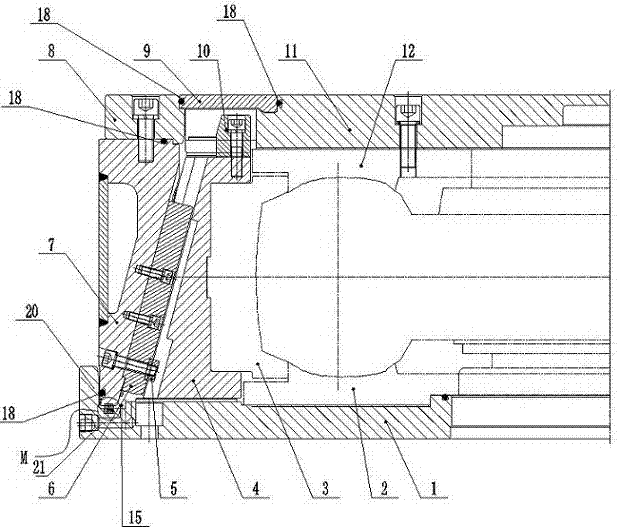

[0042] Such as Figure 1-3 As shown, the present invention provides a vacuum tire active mold, including upper side plate 12, lower side plate 2, pattern block 3, slider 4, guide bar 6, upper slider 10, guide ring 7, limit block 5 , Loam cake 11, base 1, mounting ring 8, upper sealing ring 9.

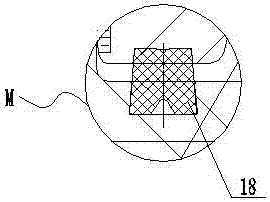

[0043] A sealing groove is arranged on the upper end surface of the base 1, and a sealing ring 18 is arranged in the sealing groove, and the sealing ring 18 cooperates with the lower end surface of the guide ring 7 to realize the end face sealing between the lower end surface of the guide ring 7 and the upper end surface of the base 1. A groove is preferably arranged on the upper end surface of the base 1, and the sealing groove is arranged in the groove.

[0044] The structure of the sealing ring 18 is preferably a trapezoidal cross section, or a semicircle, or a square, or a triangle. The bottom of the sealing ring 18 is preferably pr...

Embodiment 2

[0052] Embodiment 2 Vacuum tire flexible mold

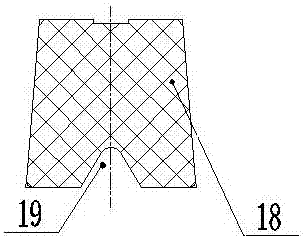

[0053] Such as Figure 4-6As shown, the present invention also provides a kind of vacuum tire flexible mould, and the difference with embodiment 1 is: also can adopt Figure 6 The sealing structure in is: the structure of the sealing ring 18 is preferably a semicircle in its cross section. The bottom of the sealing ring 18 is preferably provided with a groove 19, and the shape of the groove 19 is an inverted semicircular groove.

[0054] The upper cover 11 and the mounting ring 8 are provided with an upper sealing ring 9 and a sealing flange 13, and the mounting ring 8 and the outer circle of the mounting ring 8 and the guide ring 7 are provided with a sealing disc 14. Wherein the connecting bolts of the mounting ring 8 and the guide ring 7 can be covered by the sealing disc 14 , and can also be covered by the upper sealing ring 9 .

[0055] Wherein the sealing disc 14 is arranged outside the outer circular surface of the moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com