Hot runner temperature control instrument for plastic mold

A technology of temperature controller and plastic mold is applied in the field of temperature controller and plastic mold hot runner temperature controller, which can solve the problems of increasing labor cost and reducing work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

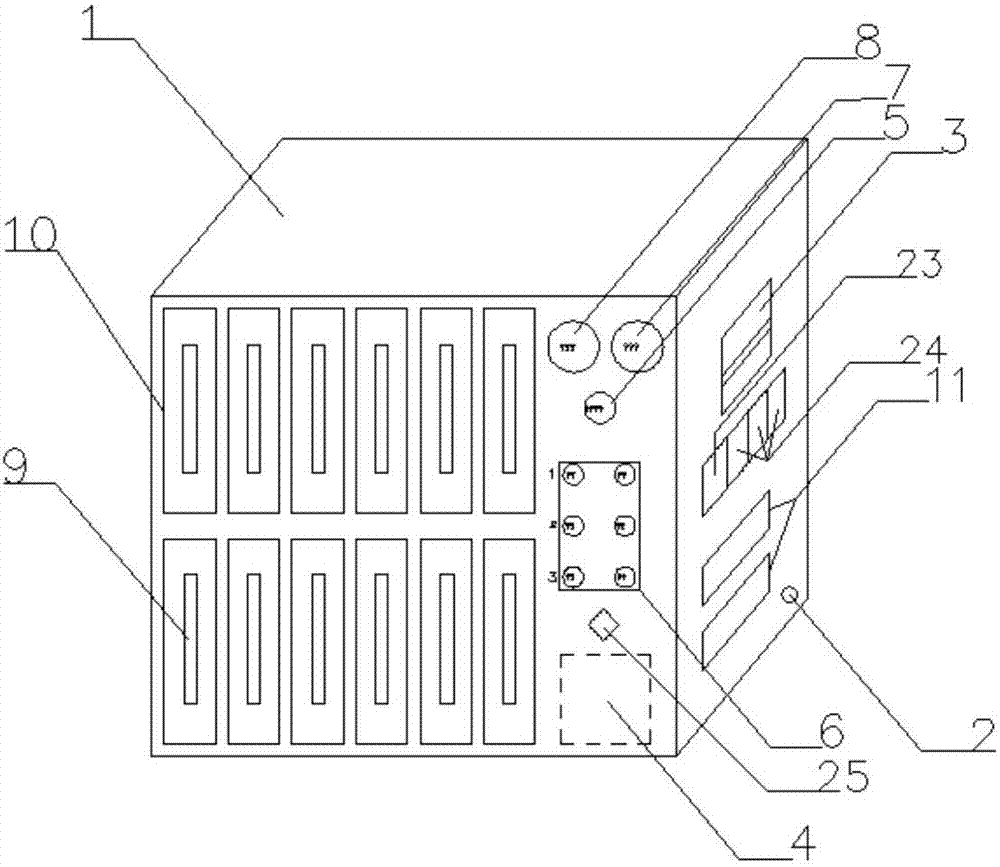

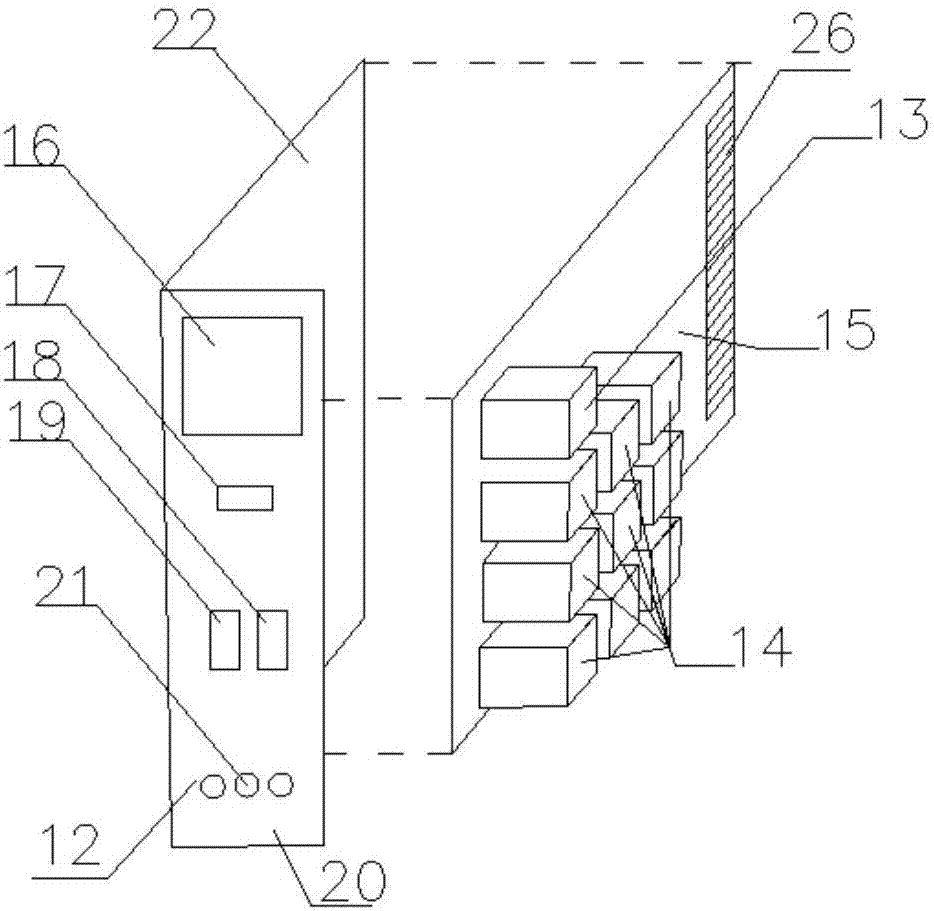

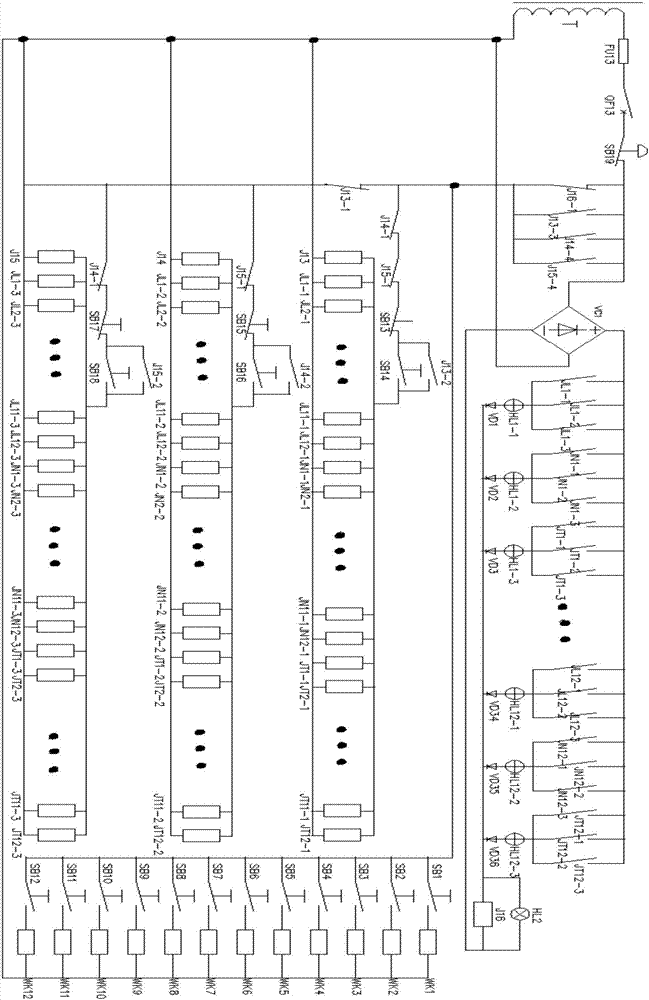

[0060] The main structure of the plastic mold hot runner temperature controller involved in this embodiment includes a main box casing 1, a power cable 2, a main switch 3, a transformer 4, an emergency stop switch 5, a start / stop button 6, and an abnormal temperature control warning light 7. Relay adhesion warning light 8, circuit board slot 9, sub-control board jack 10, 24-pin / hole industrial rectangular plug / socket 11, sub-control board 12, protection relay 23, selection relay 24 and rectifier bridge 25, such as figure 1 As shown, wherein, the sub-control board 12 includes a panel 20, a circuit board 15 and a sub-control board fixing frame 22, the panel 20 and the circuit board 15 are perpendicular to each other and embedded in the L-shaped sub-control board fixing frame 22, and the panel 20 is provided with a temperature Control meter 16, key switch 17, protection switch 18, fuse 19 and fault indicator light 21, are provided with main relay 13, sub-relay group 14 and gold f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com