Improved oxidation ditch cycle multiplication system

An oxidation ditch and aerobic zone technology, applied in chemical instruments and methods, aerobic and anaerobic process treatment, water pollutants, etc. Problems such as limited effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

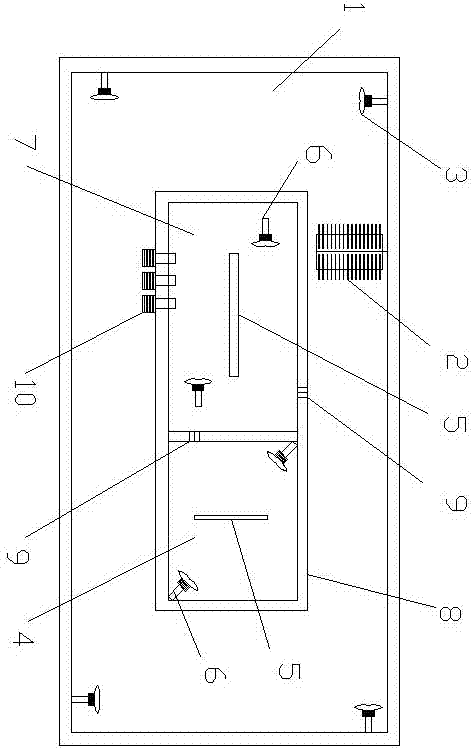

[0019] Embodiment 1: see figure 1 , this embodiment is designed for wastewater that needs nitrogen and phosphorus removal at the same time, including aerobic zone 1, aerobic zone 1 is an annular ditch, and the bottom of the ditch is evenly covered with aeration tubes 2, and aerobic zone 1 is also equipped with There is a submersible thruster 3, the anaerobic zone 4 and the anoxic zone 7 are placed in the annular ditch, and a common wall 8 is arranged between the anaerobic zone 4, the anoxic zone 7 and the aerobic zone 1; Both the oxygen zone 4 and the anoxic zone 7 are provided with a partition wall 5 and a submersible mixer 6, and the partition wall 5 and the equipped submersible mixer 6 work together to form a small hydraulic cycle; the anaerobic zone 4 and the anoxic zone 7 pass through a public The through hole 9 on the wall 8 is connected, and the anoxic zone 7 and the aerobic zone 1 are connected through the through hole 9 on the common wall 8; the nitrifying liquid in t...

Embodiment 2

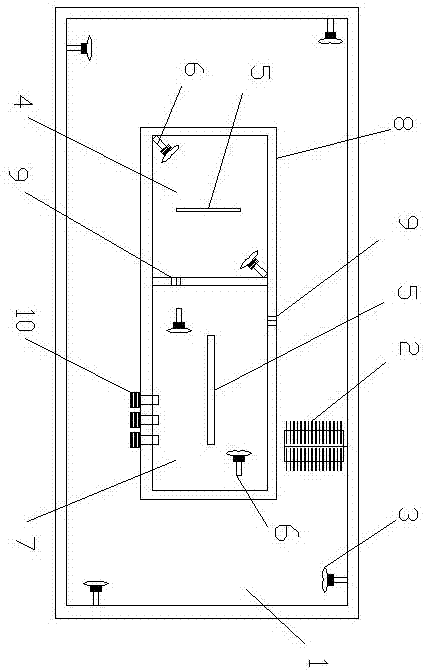

[0020] Example 2: see figure 2 , as in Example 1, the influent and return sludge first enter the anoxic zone 7, then enter the anaerobic zone 4 and the aerobic zone 1 in turn, forming an improved inverted A 2 / O oxidation ditch system.

Embodiment 3

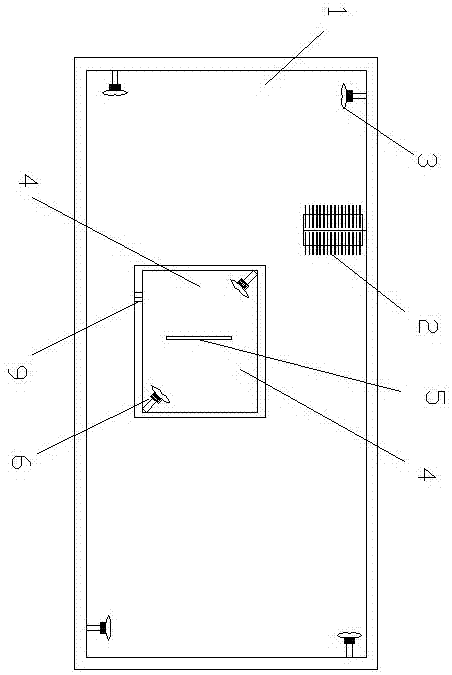

[0021] Embodiment 3: see image 3 , designed for wastewater that only needs to remove phosphorus but not nitrogen, as in Example 1, reduce the link of the anoxic zone 7 and the return pump 10 in the annular ditch to achieve the purpose of removing pollutants such as phosphorus and organic matter, and form an improved A / O (anaerobic / aerobic) oxidation ditch system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com