Sludge dehumidifying and drying device

A technology of sludge and jet device, applied in sludge treatment, water/sludge/sewage treatment, dewatering/drying/concentrated sludge treatment, etc., can solve the problems of high fabrication difficulty, poor equipment stability, complex equipment structure, etc. , to reduce the moisture content and improve the drying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

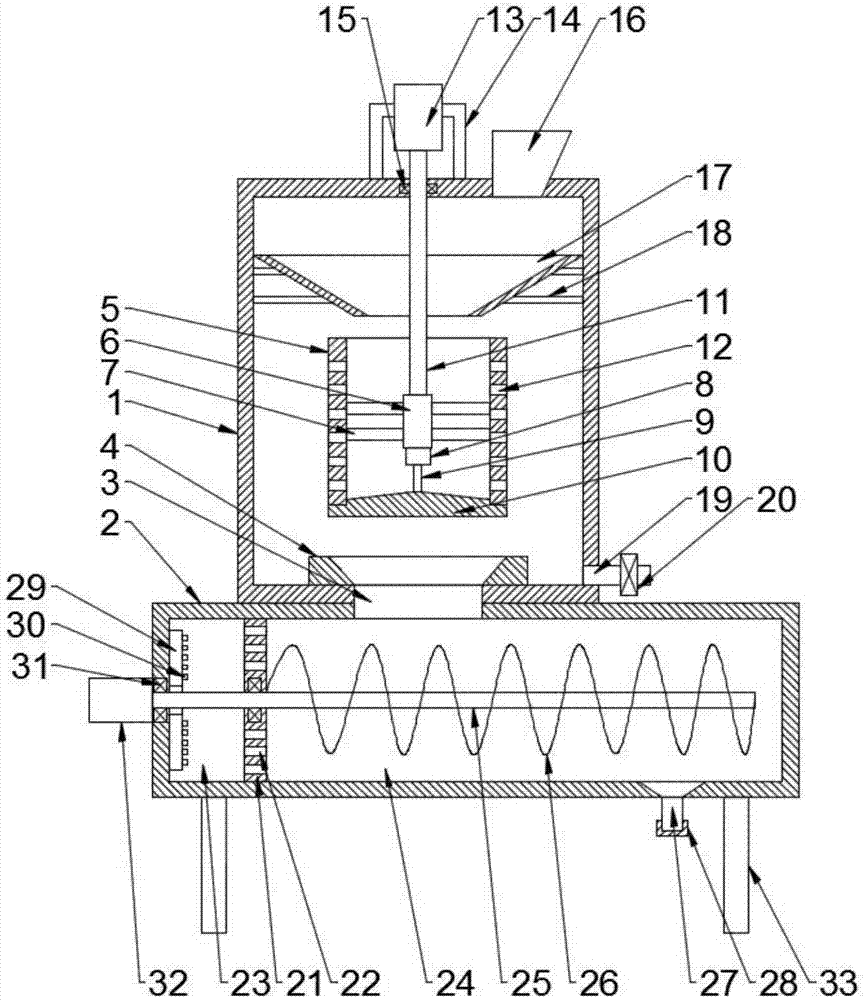

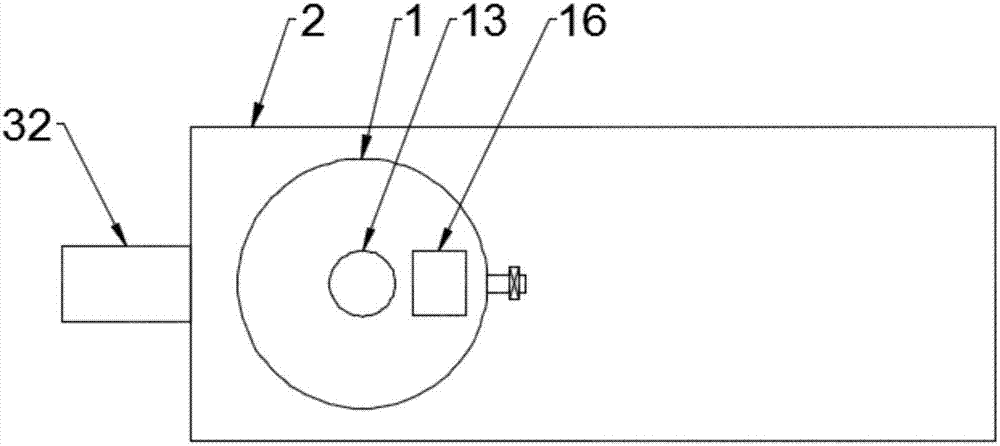

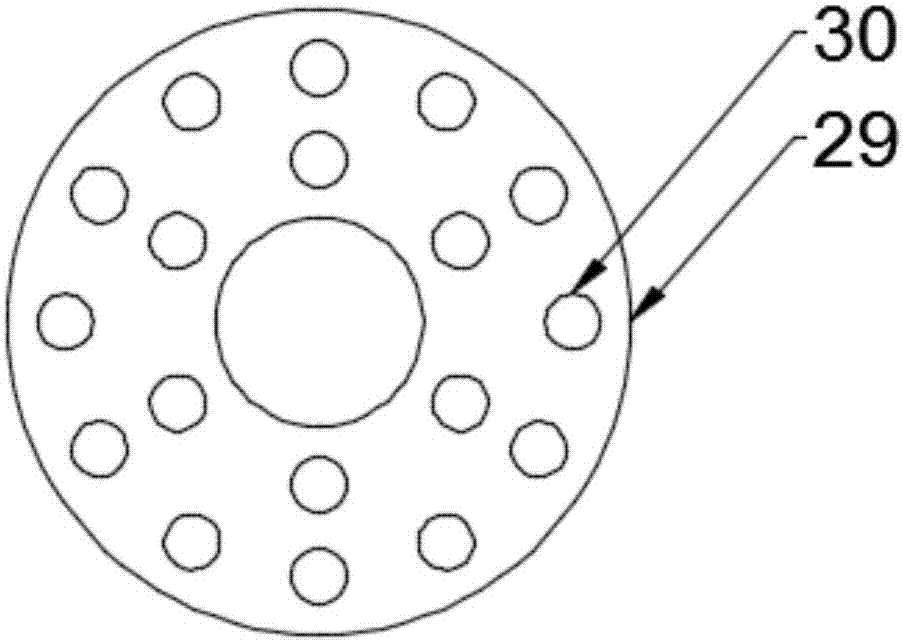

[0019] see Figure 1~3 , a sludge dehumidification and drying device, including a dehydration box 1 and a drying box 2, the dehydration box 1 is a cylindrical structure design, the dehydration box 1 is fixedly connected to the left side of the top surface of the drying box 1, the dehydration box 1 is through-connected with the drying box 2 through the communication hole 3, the top of the communication hole 3 is connected to the first guide hopper 4, and the middle part of the inner cavity of the dehydration box 1 is provided with a water-spinning cylinder 5, and the water-spinning cylinder 5 is at the upper and lower ends They are all designed in an open cylindrical structure, the axis of the water-spinning cylinder 5 coincides with the axis of the dehydration tank 1, and a number of dehydration holes 12 are uniformly arranged on the side wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com