Preparation method for glass plate with color ink pattern, and glass plate

A color ink, glass plate technology, applied in the direction of coating, can solve the problems such as the edge is not straight enough, the color ink texture is poor in resolution, and the appearance of the glass plate product is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

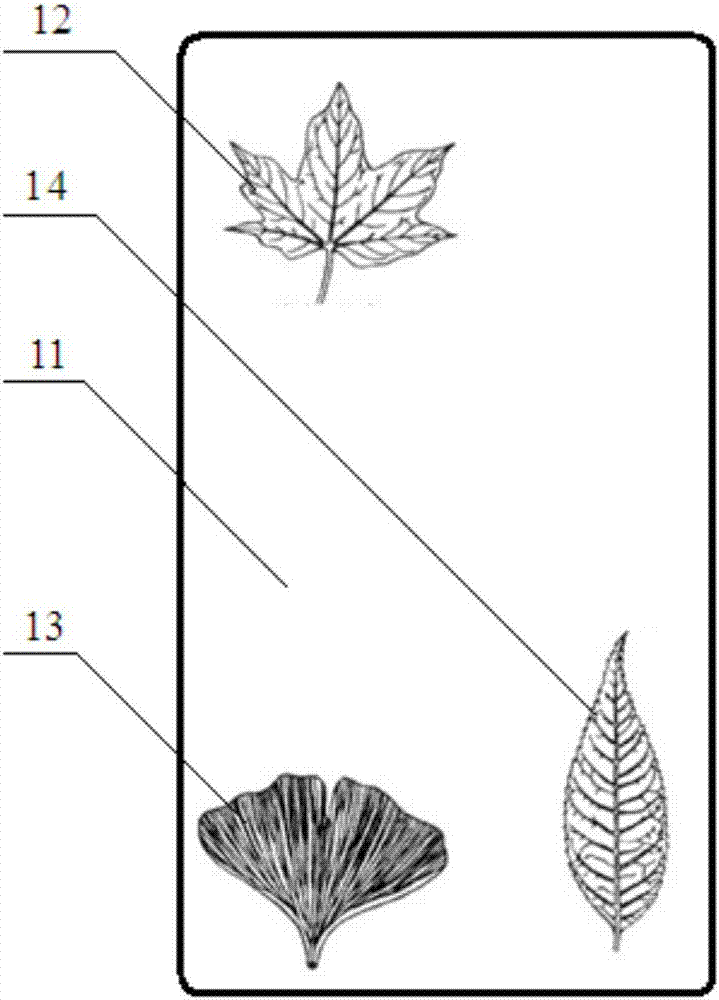

Embodiment 1

[0041] The purpose of this embodiment is to form vein patterns of red, yellow and green on a 3D glass cover plate with a white base color, wherein the line width of the vein pattern is within 10-70 microns according to the difference between the main vein and the branch veins . The method comprises the steps of:

[0042] Step a, cleaning the strengthened glass substrate;

[0043] Step b. Coating the positive wet film photoresist on the whole surface of the clean glass substrate and pre-baking the wet film photoresist, and then developing and removing the photoresist at the position where the red ink pattern pattern needs to be finally formed through the exposure and development process ; The photomask used in the exposure process contains the same pattern as the red ink pattern as the light-transmitting part;

[0044] Step c, spraying red ink on the entire surface of the photoresist surface of the glass substrate obtained in step b, and baking and fixing the ink;

[0045] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com