In-hole point anchor slide-resistant pile barricade

A technology of anti-sliding piles and retaining walls, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as difficulty in preventing emergencies, long time of anti-sliding effect, cumbersome construction, etc., and achieve short construction period , low cost, and structural safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

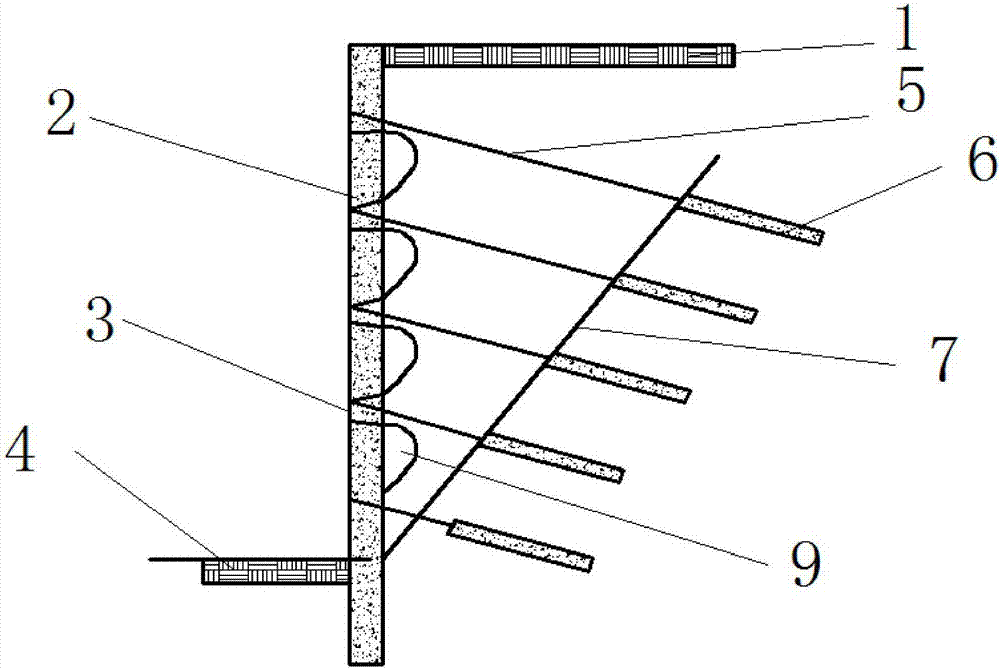

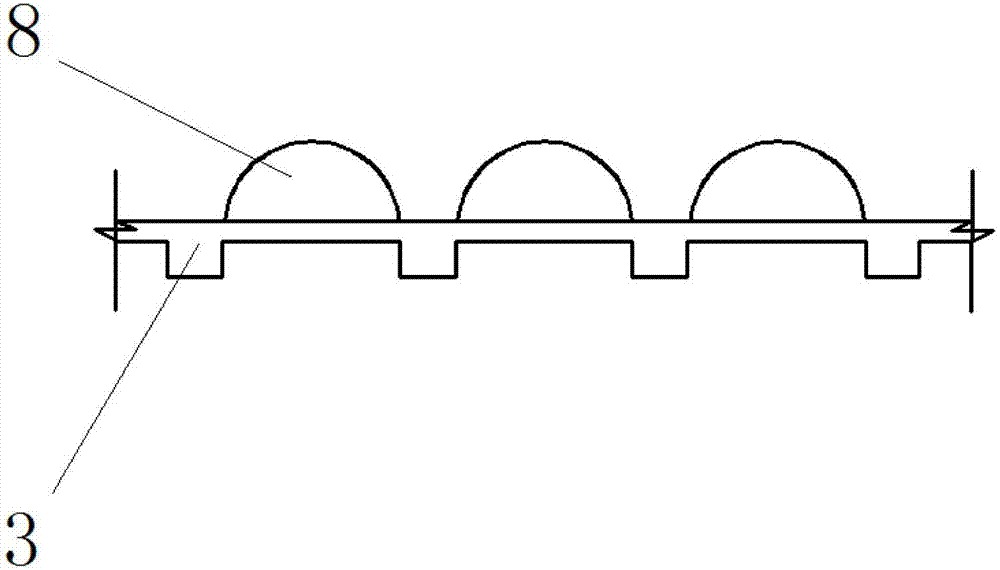

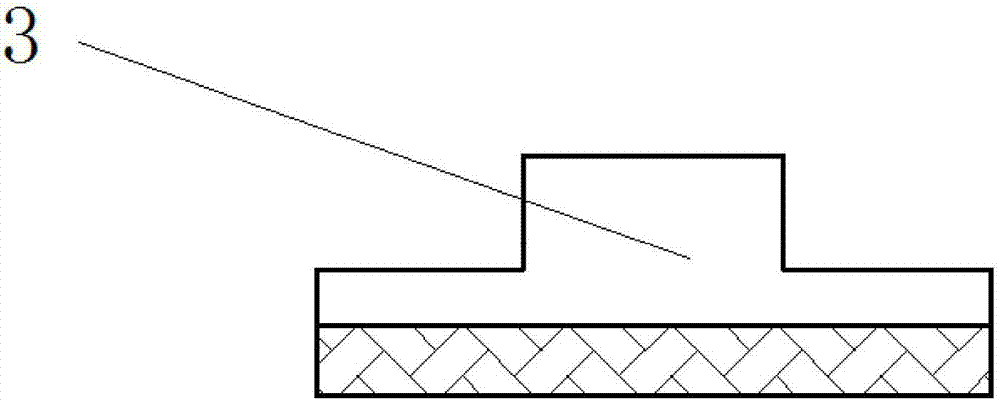

[0015] Example: see Figure 1-3 , the present invention is a new type of in-hole point anchor anti-slide pile retaining wall. An anti-slide pile 2 is arranged in between, and the surface of the anti-slide pile 2 is provided with an anchor cable 5 at intervals, and one end of the anchor cable 5 is provided with an anchor section 6, and a point anchor is provided between the anchor cable 5 and the anti-slide pile 2 3. There is a horizontal collapse arch 8 and a vertical collapse arch 9 between the point anchors 3, a slip fracture surface 7 is provided between the anchor section 6 and the anchor cable 5, and the anchor section 6 is set on the slip fracture surface. Inside face 7.

[0016] The bottom of the anti-slide pile 2 is arranged in the soil layer at the bottom of the slope 4 .

[0017] It should be noted that the present invention is a new type of point-anchor anti-slide pile retaining wall in the hole. The beam structure of the traditional anti-slide pile is changed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com