Heightening and strengthening structure and method for in-service steel bar concrete retaining wall

A reinforced concrete and reinforced structure technology, which is applied in the field of reinforced concrete retaining walls in service, can solve problems such as no longer applicable retaining walls, slope instability, external drums, etc., to increase the overturning resistance and stability, increasing anti-slip and overall stability, ensuring safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

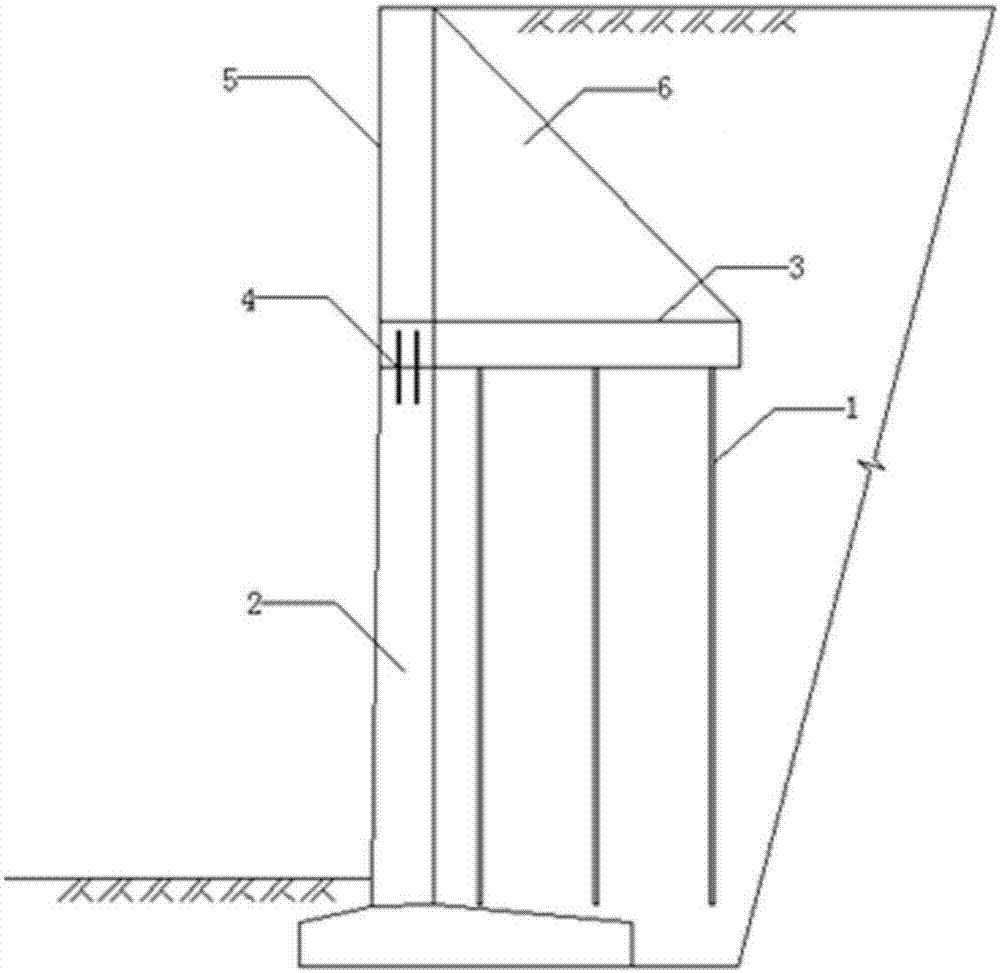

[0035] The original height of the subgrade slope in a section in Shenyang, Liaoning is 5.5m, and the length is about 100m. The strata from top to bottom are: 1.0-3.0m thick plain fill, 2.0-3.5m thick silty clay, 2.0-3.8m thick fully weathered mudstone, Below the fully weathered mudstone is strongly weathered sandy mudstone with a thickness greater than 6.0m. The original reinforced concrete retaining wall in service is a cantilever reinforced concrete retaining wall. The bearing capacity of the side slope wall after plain fill is compacted f ak =110~130Kpa. The retaining wall has been in operation for many years. Due to the heightening of the roadbed, the height of the original retaining wall needs to be increased by 4.5m according to the existing planning.

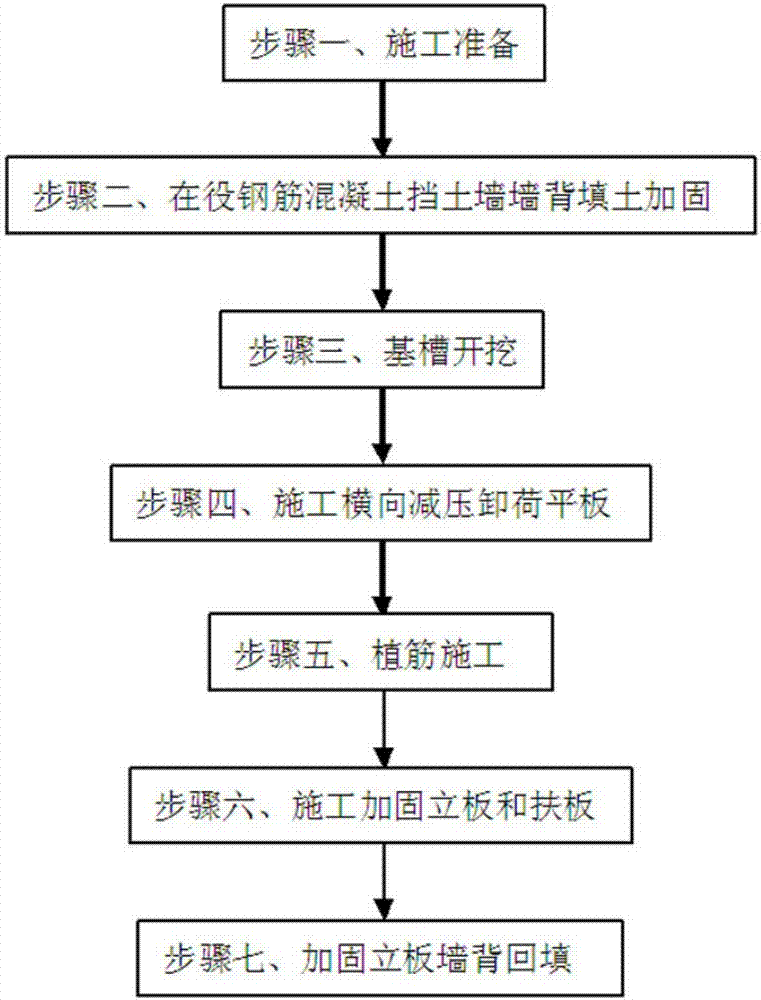

[0036] The heightening and strengthening measures of the retaining wall are as follows, please refer to the specific form figure 1 : The fill behind the original retaining wall adopts split grouting, the grouting pipe 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com