Tool for preventing drill bit torque from being too high

An oversized, drill bit technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of downhole drilling tools such as damage to measuring instruments while drilling, drilling tool breakage, and affecting drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

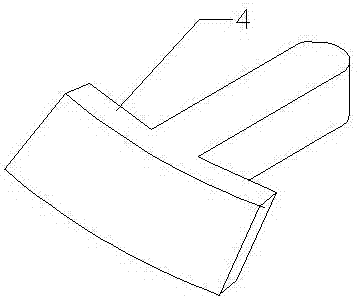

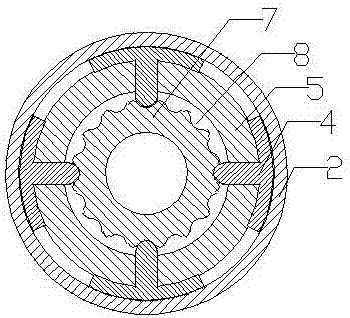

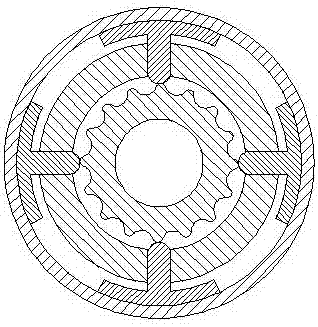

[0019] The tool for preventing excessive torque of the drill bit includes an upper joint 1, a disc spring 3, a cone sleeve 2, a push piece 4, a transmission shaft 5 and an output shaft 7; There is output shaft 7. The transmission shaft 5 and the output shaft 7 are reducing bodies respectively, and a seal 6 is arranged between the transmission shaft 5 and the output shaft 7 to prevent impurities in the wellbore from entering the drilling fluid flow path from between the transmission shaft 5 and the output shaft 7 .

[0020] The transmission shaft 5 is covered with a tapered sleeve 2, and a disc spring 3 is arranged between the tapered sleeve 2 and the upper joint 1. Mounting holes are evenly distributed on the circumference of the upper end of the transmission shaft 5, and push pieces 4 are movable in the mounting holes. There are four mounting holes and four push pieces 4 respectively.

[0021] The push piece 4 is T-shaped; the output shaft 7 corresponding to the push piece 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com