Deep water gravity type spiral automatic connector

A gravity type, connector technology, used in wellbore/well components, earthmoving, sealing/packing, etc., can solve the problems of low coping ability, complicated operation and high connector cost in unknown marine environment, and achieve structural Simple, easy to operate, clever overall design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

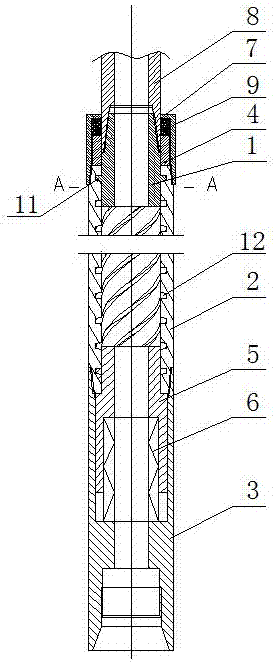

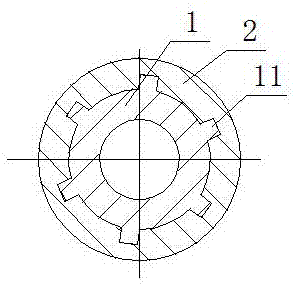

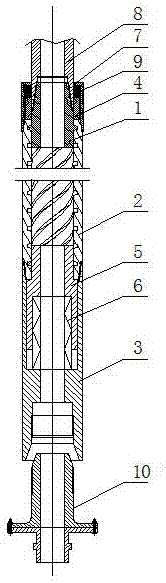

[0018] The deep water gravity screw automatic connector consists of a screw power head 1, a screw joint 2, a connecting shell 3, an upper limit sleeve 4, a lower limit sleeve 5, a disc spring 6 and an end cover 7, and the lower end of the screw joint 2 is threaded. A connection shell 3 is installed, and a screw power head 1 is arranged inside the screw motion nipple 2, and a riser 8 is installed on the top thread of the screw power head 1, and an end cap 7 is installed on the top thread of the screw motion nipple 2, and the end cap 7 is connected with the water riser 8 and the screw power head 1 are equipped with an upper limit sleeve 4 through a sealing ring 9, and the end cover 7 is slidably connected with the riser 8, the screw power head 1 and the upper limit sleeve 4. The sealing ring 9 is installed on the upper part of the upper limit sleeve 4, and the sealing ring 9 can prevent impurities in the ocean from entering the inside of the tool, so as to avoid affecting the nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com