Multifunctional reinforcing steel bar laying-off device and laying-off method

A technology of multi-function and reclaiming device, applied in the field of blanking device and multi-functional steel bar blanking device, can solve the problems of large friction force of moving steel bar, not properly solved, and large error of blanking size, so as to improve the efficiency and the overall Cleverly designed, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

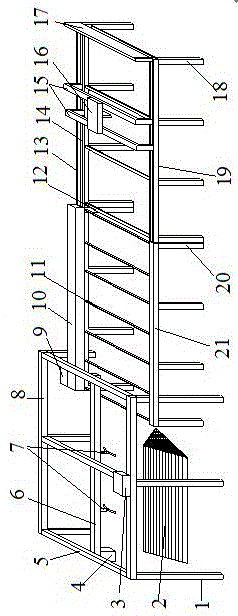

[0015] Embodiment 1: see figure 1 , a multifunctional steel bar unloading device, the unloading device includes a retrieving device, a conveying device and a cutting device, the conveying device is arranged between the retrieving device and the cutting device, and the retrieving device includes a retrieving pillar , guide rail drive motor, manipulator drive motor, vertical guide rail, horizontal guide rail, telescopic manipulator and reclaiming beam, retrieving beam 8 is installed on the upper end of reclaiming pillar 1, three vertical guide rails 5 are installed on retrieving beam 8, and horizontal guide rail 6 is installed in the vertical guide rail 5, and the guide rail driving motor 3 is installed in the middle part of the retrieving beam 8, which can drive the horizontal guide rail 6 to move in the vertical guide rail 5, and the manipulator driving motor 4 is installed on one end of the horizontal guide rail 6, two The telescopic manipulator 7 is installed in the transver...

Embodiment 2

[0016] Example 2: see figure 1 , a method for unloading a multi-functional steel bar unloading device, characterized in that: the method is as follows: 1) take out steel bar 2, use the guide rail drive motor 4 to drive the transverse guide rail 6 to move to the top of the steel bar 2, and then turn on the manipulator to drive The motor 4 makes the telescopic manipulator 7 move in the horizontal guide rail 6 to reach the stacking position of the steel bar 2, and stretches down to the steel bar 2 to grab the steel bar 2, then retracts to the original position, and then moves along the horizontal guide rail 6 to reach the conveying device Place the steel bar 2 on the rubber-covered roller by moving downward, and repeat the above steps to take out the steel bar 2; 2) For the transmission of the steel bar 2, the transmission gear box 10 is driven by the transmission motor 9 to drive the rubber-coated roller 11 to rotate , transfer the steel bar 2 placed on the rubber-covered roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com