Rigidity-adjustable water lubricating stem bearing

A stern bearing and water-lubricated technology, applied in sliding contact bearings, bearings, flexible bearings, etc., can solve the problems of inability to adjust the stiffness of water-lubricated bearings, maintenance cycle and maintenance workload, etc., and achieve large-scale engineering application value and economic benefits. , The effect of reducing maintenance costs and reducing shaft vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

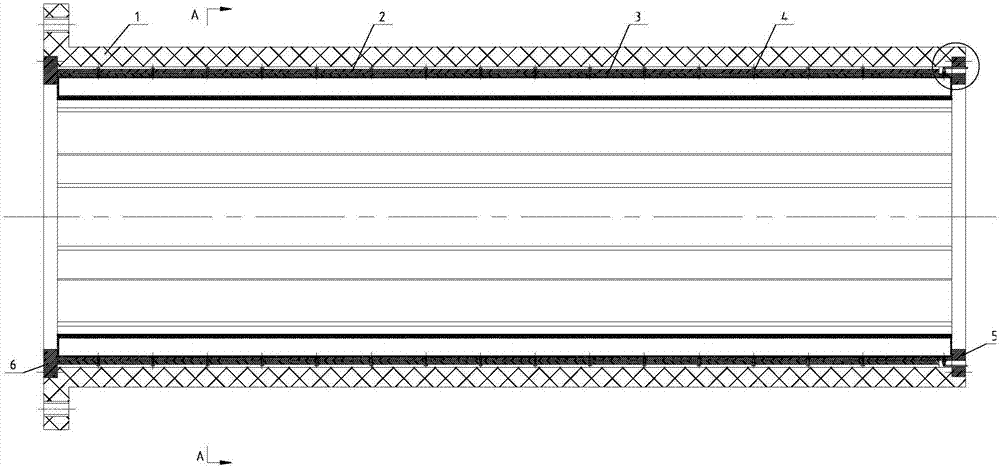

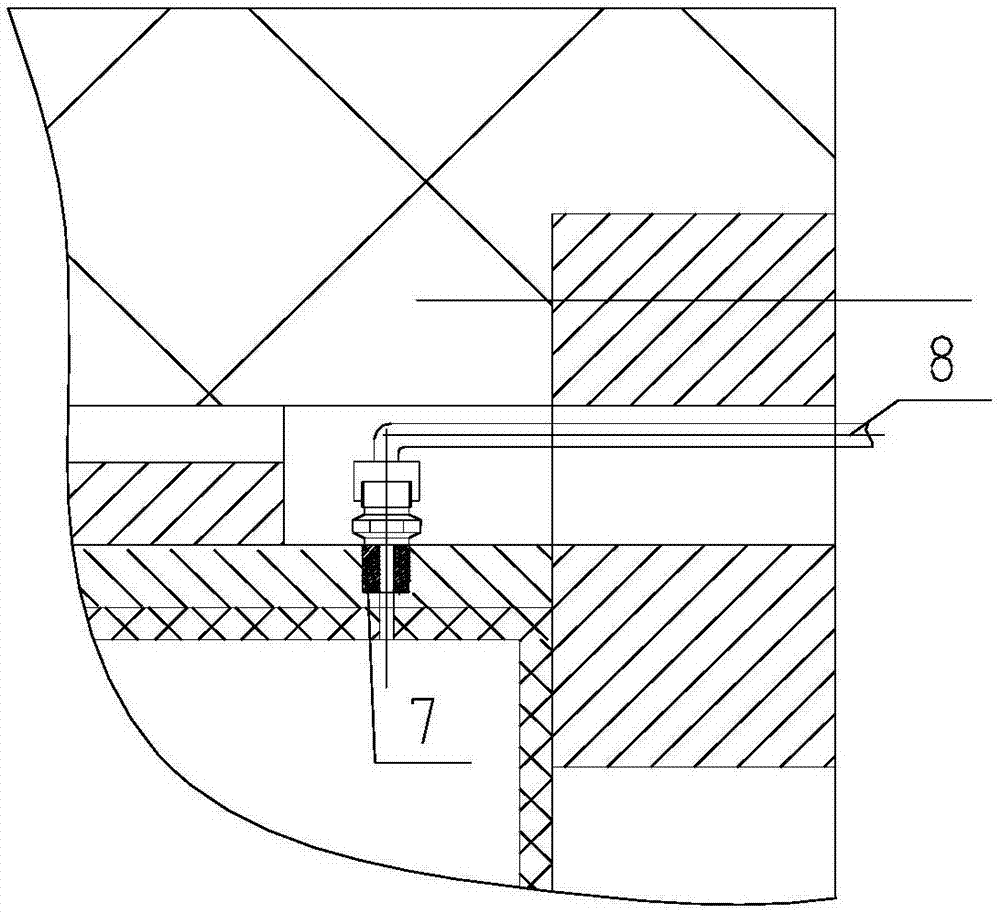

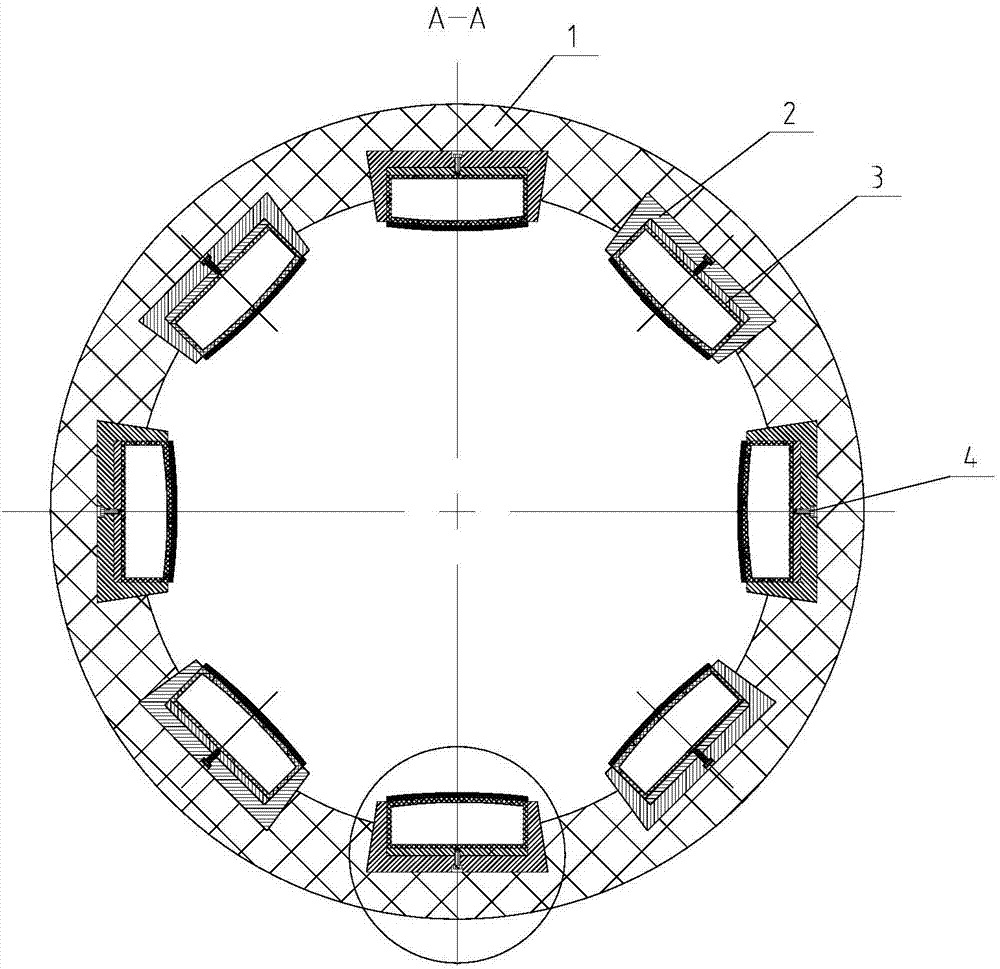

[0021] like figure 1 , figure 2 , image 3 , Figure 4 As shown, one embodiment of the present invention is a water-lubricated stern bearing with adjustable stiffness. The outer surface of the bearing bush 1 is cylindrical, and it is installed in the bearing hub through the bolt holes on its flange. The dovetail groove structure is arranged, and the bearing support is installed inside the dovetail groove structure along the axial direction

[0022] as attached image 3 As shown, the cross-sectional shape of the bearing support 2 is a dovetail groove shape, the back of the bearing support is installed on the bearing bush 1, a rectangular groove is opened on the back of the bearing support 2 along the axial direction, and the front of the bearing support 2 is concave. Shaped structure, the back of the adjustable bearing pad 3 is also a rectangular stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com