Bamboo board molding stamping machine computer control method

A control method and stamping machine technology, applied in the direction of computer control, program control, general control system, etc., can solve the problems of no strict discrimination method, uneven carbonization degree, and limitation of reorganized bamboo flooring, so as to save energy loss and raw materials The effect of simplification of loss and carbonization control process and reduction of temperature control requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

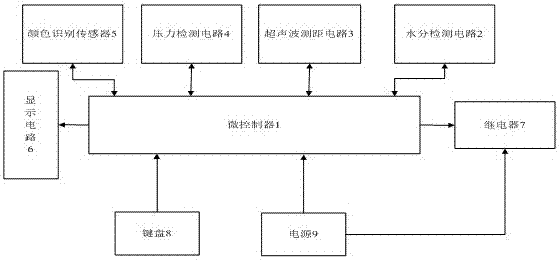

[0013] Such as figure 1 As shown, the control device of the bamboo sheet forming punching machine consists of a microcontroller 1, a moisture detection circuit 2, an ultrasonic distance measuring circuit 3, a pressure detection circuit 4, a color recognition sensor 5, a display circuit 6, a relay 7, a keyboard 8 and a power supply 9 circuit. Composition, the microcontroller 1 receives the signals from the keyboard 8, the moisture detection circuit 2, the ultrasonic distance measuring circuit 3, the pressure detection circuit 4 and the color recognition sensor 5, outputs the signals to the display circuit 6 for display, and sends the processed signals to the relay 7 To control the start and stop of the punching machine, the microcontroller 1 weights and sums the signals of the sensors and the detection circuit to determine whether the punched bamboo board is qualified. The power circuit 9 provides power to the microcontroller 1 and the relay 7.

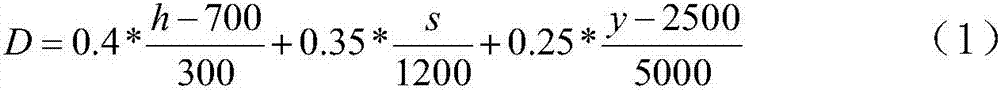

[0014] After the bamboo filament s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com