Mechanical constant temperature adjusting method for experiment

A constant temperature adjustment and mechanical technology, applied in the field of chemical experiments, can solve the problems of unfavorable popularization and application, high purchase cost and high maintenance cost, and achieve the effects of simple and convenient control process, reduced equipment cost and maintenance cost, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

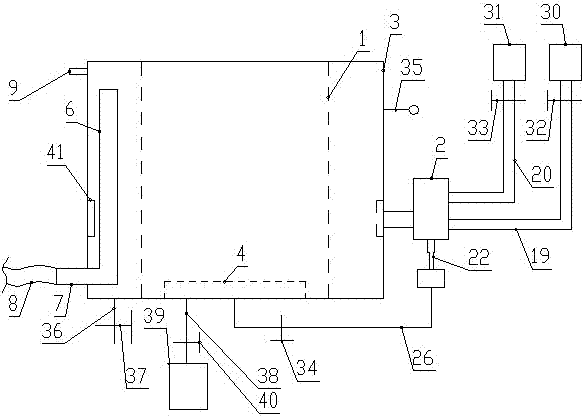

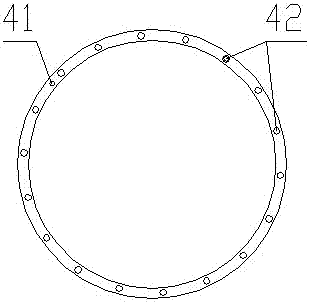

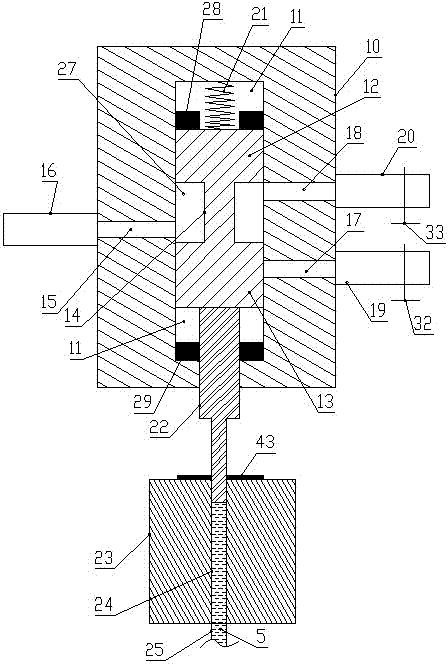

[0037] The invention discloses a mechanical constant temperature adjustment method for experiments, which is carried out by using a constant temperature water bath system. Such as Figure 1 to Figure 5 As shown, the constant temperature water bath system includes a constant temperature box 1 and a temperature control valve 2, the outer wall of the constant temperature box 1 is provided with a water jacket 3, the bottom of the constant temperature box 1 is provided with a temperature sensing package 4, and the temperature sensing package 4 is filled with an expansion fluid 5; The jacket 3 is provided with an overflow pipe 6, the upper end of the overflow pipe 6 is located at the top of the water jacket 3 and is open, and the lower end of the overflow pipe 6 is located at the bottom of the water jacket 3 and is bent to provide a horizontal pipe section 7, the horizontal pipe section 7 protruding from the side wall of the water jacket 3; the outer end of the horizontal pipe secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com