Automatic winding device applicable to electromagnetic induction coils and winding method of automatic winding device

An electromagnetic induction coil and wire winding technology, which is used in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc. The effect of processing cost, saving processing cost and avoiding short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

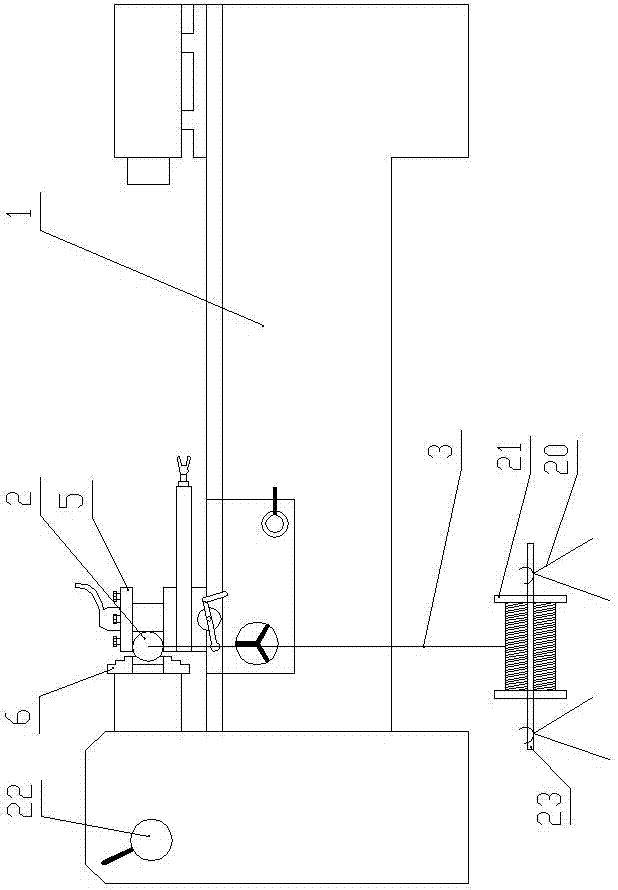

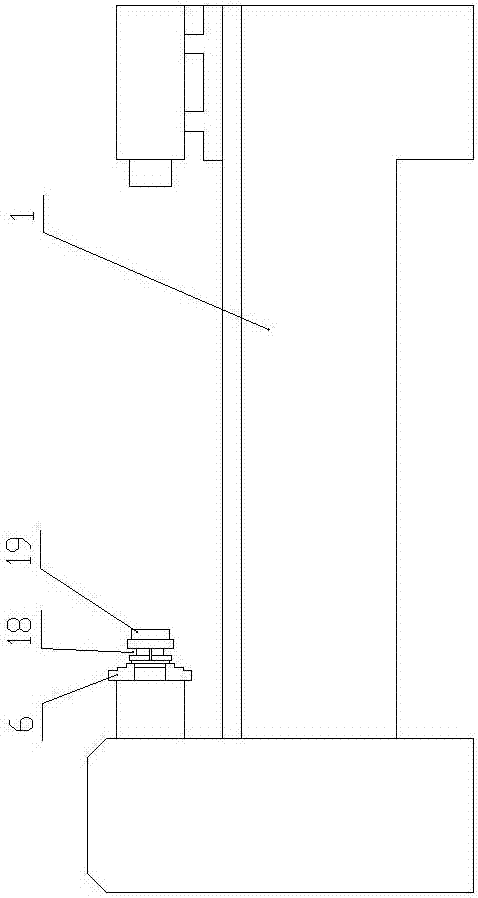

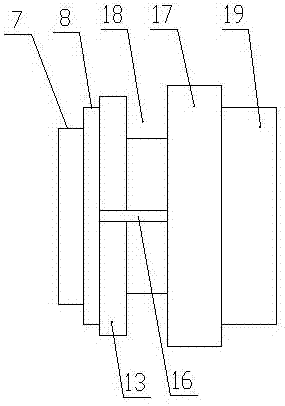

[0035] Such as Figure 1 to Figure 7 shown in figure 1 The left side of the left side is the left side of the present invention. A kind of automatic winding device suitable for electromagnetic induction coils of the present invention includes a horizontal lathe 1, a winding mold, a silica gel column 2 and an enameled wire 3, and the winding mold is fixed and clamped on On the horizontal lathe 1, the center of the silica gel column 2 is axially opened with a pre-tightening hole 4 for the enameled wire 3 to pass through. The diameter of the pre-tightening hole 4 is the same as that of the enameled wire 3, and the silica gel column 2 is fixed and clamped along the front and rear horizontal directions. On the tool post 5 of the horizontal lathe 1, one end of the enameled wire 3 passes through the pre-tightening hole 4 of the silica gel column 2 and the winding mold in turn, and is fixed with one of the jaws of the three-jaw chuck 6 of the horizontal lathe 1 by winding connect.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com