Green husk walnut microcapsule powder and preparation method thereof

A technology of microcapsule powder and walnut green peel powder, which is applied in the fields of walnut processing and food processing, can solve the problems of nutrient loss, bitter taste of walnut green peel, waste of walnut green peel, etc. Effects of Taste Defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment one: green walnut microcapsule powder

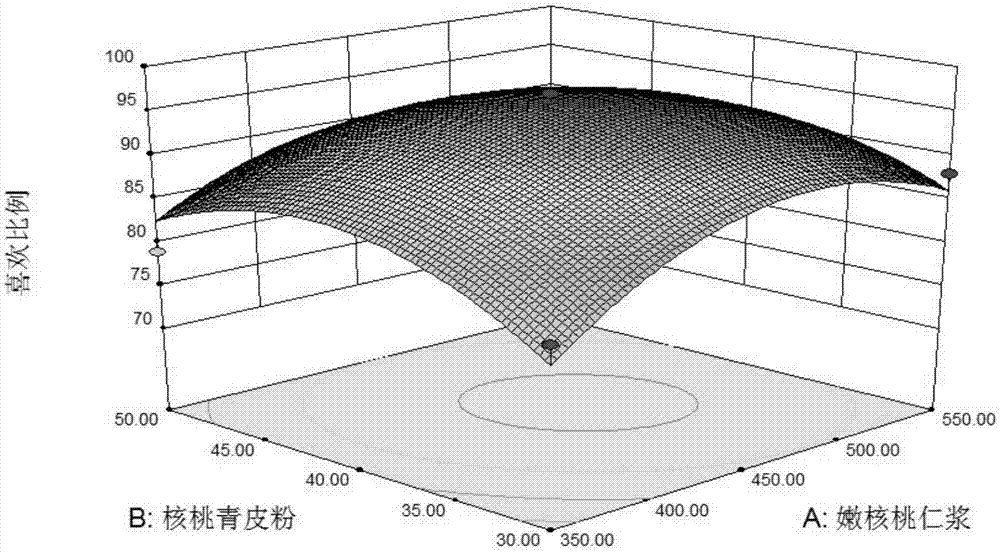

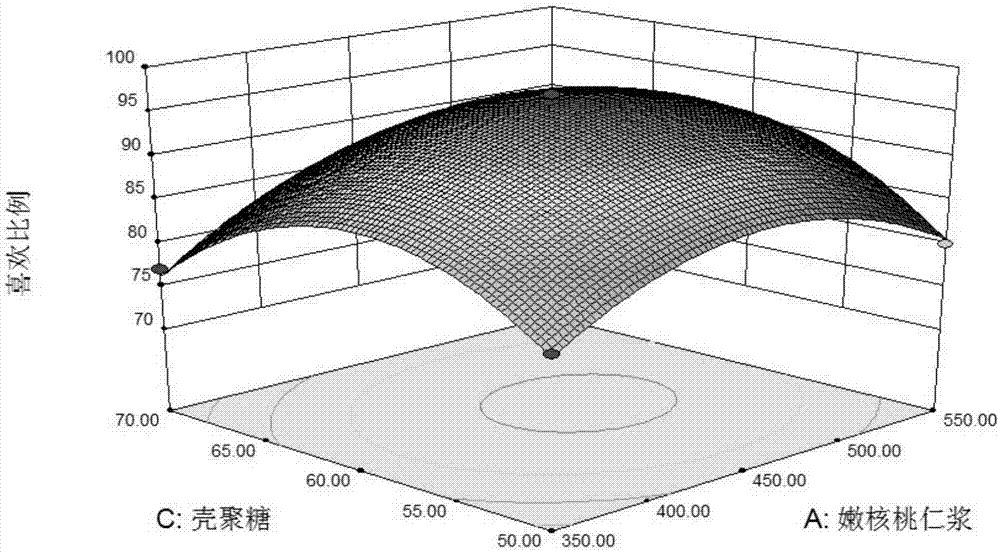

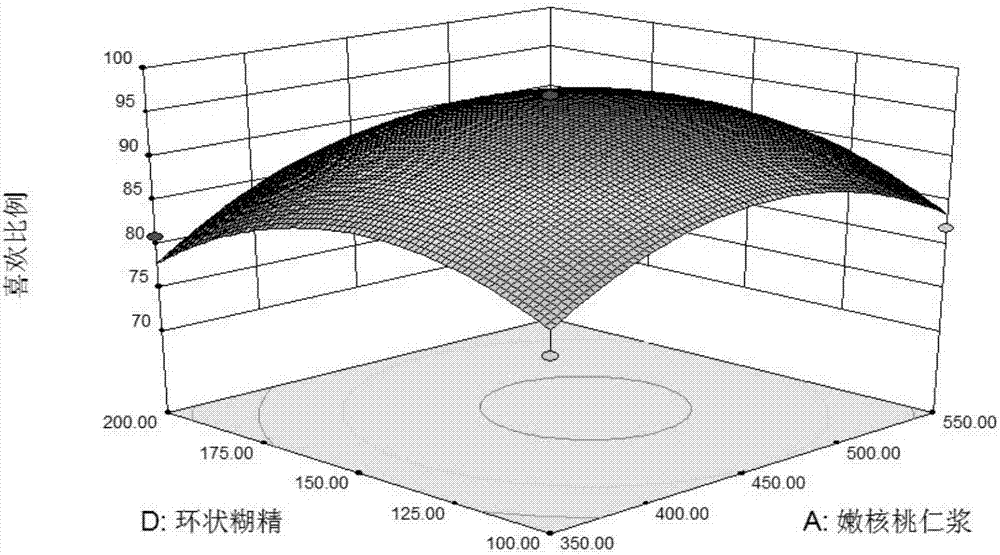

[0030] The invention specifically provides a green walnut microcapsule powder, which is prepared by taking young walnut pulp and walnut green peel powder as core materials, and using chitosan, β-cyclodextrin and gelatin as wall materials; It includes 20-60 parts of tender walnut pulp, 1-5 parts of walnut green skin powder, 1-10 parts of chitosan, 5-25 parts of β-cyclodextrin, and 1-10 parts of gelatin.

[0031] Preferably, the present invention provides a green walnut microcapsule powder, which is prepared from tender walnut pulp and walnut green peel powder as core materials, and chitosan, β-cyclodextrin and gelatin as wall materials; In terms of parts by weight, it includes 35-55 parts of tender walnut pulp, 3-5 parts of walnut green skin powder, 5-7 parts of chitosan, 10-20 parts of β-cyclodextrin, and 2 parts- 5 servings.

[0032] More preferably, the present invention provides a green walnut microcapsule powder, ...

Embodiment 2

[0033] Embodiment two: the preparation method of green walnut microcapsule powder

[0034] On July 10th, fresh walnuts were picked before they were fully ripe. During the half pulp and half water state of the walnuts before they were fully ripe, the green skins were removed and impurities were removed; the obtained walnut green skins were quickly frozen at -75°C into hard frozen green skins. After that, it is crushed at a high speed into walnut green skin powder; the fresh walnuts that have been peeled off are broken into shells, the shells and walnut kernels are separated, and the tender walnut kernels are beaten at a speed of 5000r / min to become walnut pulp; the walnut pulp, walnut green peel powder, and shell Add all the sugar into deionized water, stir and mix, then add β-cyclodextrin and gelatin, continue to stir and mix evenly, transfer to an atomizing dryer and spray dry at a temperature of 120°C to obtain green walnut microcapsule powder.

Embodiment 3

[0035] Embodiment three: the preparation method of green walnut microcapsule powder

[0036] Pick fresh walnuts before they are fully ripe on July 20. During the half pulp and half water state of the walnuts before they are fully ripe, the green skins are removed and impurities are removed; the obtained walnut green skins are quickly frozen at -55°C into hard frozen green skins. Grinding at high speed into walnut green skin powder; breaking the fresh walnut shells off, separating the shells and walnut kernels, taking tender walnut kernels and beating at a speed of 6000r / min to form walnut pulp; mixing walnut pulp, walnut green peel powder, chitosan All were added into deionized water, stirred and mixed, then β-cyclodextrin and gelatin were added, continuously stirred and mixed evenly, transferred to an atomizing dryer and spray-dried at a temperature of 130° C. to obtain green walnut microcapsule powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com