Microporous atomizing sheet

A technology of microporous atomization and atomization holes, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of small mist output, easy generation of bubbles, complicated processing, etc., to reduce power consumption, facilitate welding, and simple processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the drawings. The following embodiments are only used to explain the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

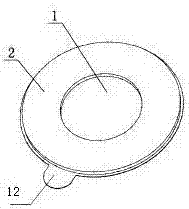

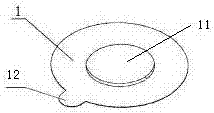

[0017] Such as figure 1 , 2 , 3, 4, and 5, a microporous atomizing sheet includes a metal diaphragm 1 and a ring-shaped piezoelectric ceramic sheet 2. The metal diaphragm 1 is mounted on the lower part of the piezoelectric ceramic sheet 2 and has an area larger than the piezoelectric ceramic sheet. The area of the ceramic sheet 2, the thickness of the metal diaphragm 1 is 0.06mm ~ 0.08mm, the metal diaphragm 1 is designed as a circular sheet, and the metal diaphragm 1 is in the ring of the piezoelectric ceramic sheet 2 A protrusion 11 is partially provided, and the piezoelectric ceramic sheet 2 is correspondingly designed as a circular sheet-shaped body with an outer diameter smaller than that of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com