Mobile phone screen disassembling equipment

A device and mobile phone technology, applied in the field of mobile phone screen removal equipment, can solve the problems of damage to the internal components of the mobile phone, time-consuming, toxic, etc., to avoid burns and chemical damage, convenient and fast operation, and improve the effect of safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

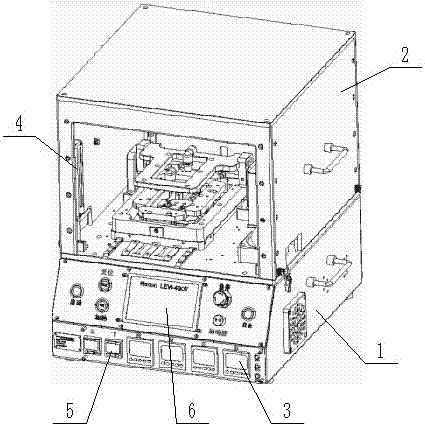

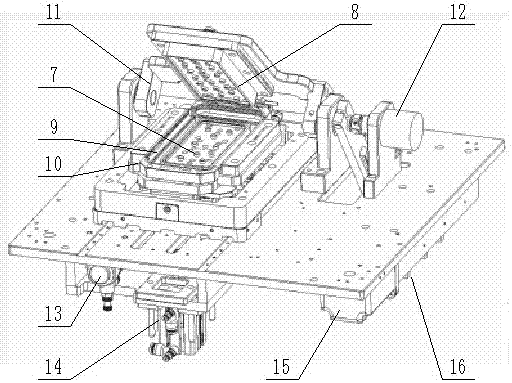

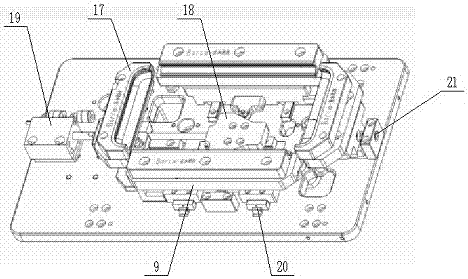

[0029] see Figure 1-7 , a mobile phone screen removal device, including a device body, the device body is provided with a box body 1, a transparent protective cover 2 is arranged above the box body 1, a safety grating 4 is arranged on the end face of the transparent protective cover 2, and the safety grating 4 It is fixedly connected with the transparent protective cover 2, and the end face of the box body 1 is provided with a temperature controller 3, a negative pressure gauge 5 and a display screen 6, and the temperature controller 3 uses a digital display thermostat to control the temperature to realize continuous and adjustable temperature Adjustment, the inside of the device body is provided with a screen-removing structure, and the screen-removing structure is provided with a working panel, and the working panel is fixedly connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com