High-density modular magnetic torquer applied to micro-nano satellite and design method

A magnetic torque device and micro-nano-satellite technology, applied in the direction of aerospace vehicle guidance devices, etc., can solve the problems of large number of circuit boards, complex cables, equipment impact, etc., achieve high density and integration, reduce launch costs, and facilitate installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

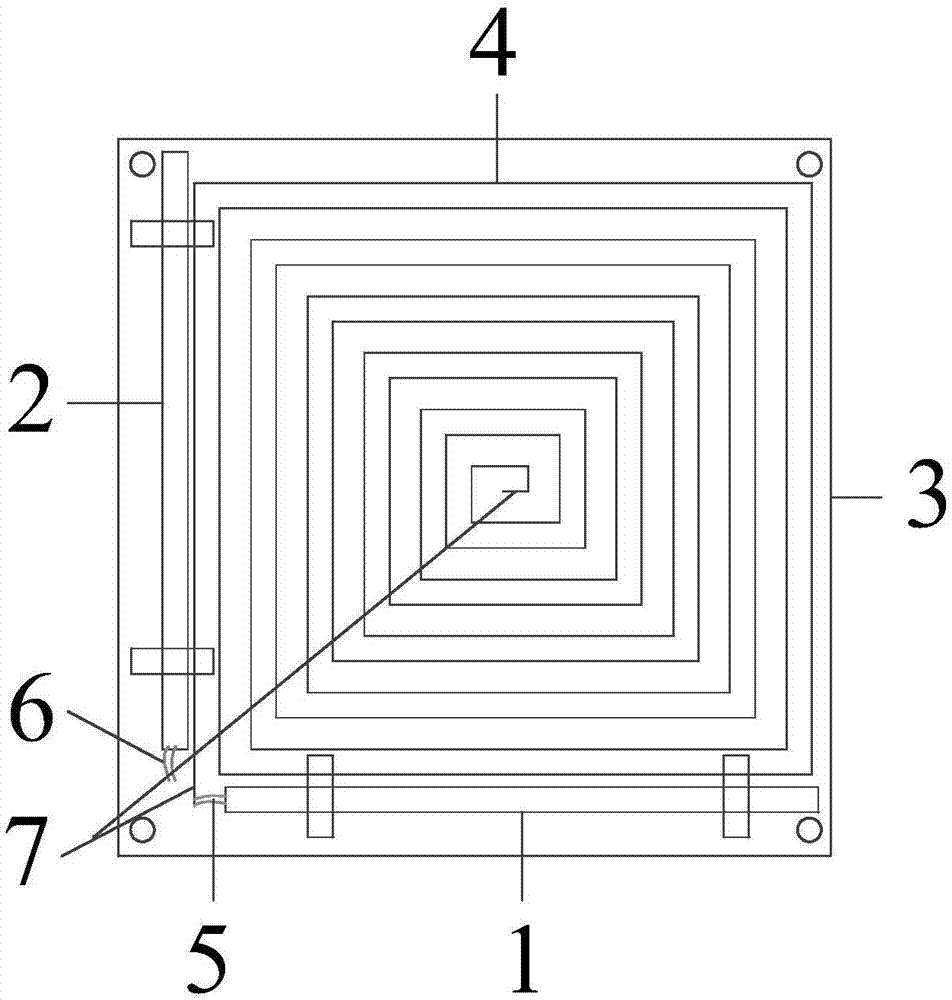

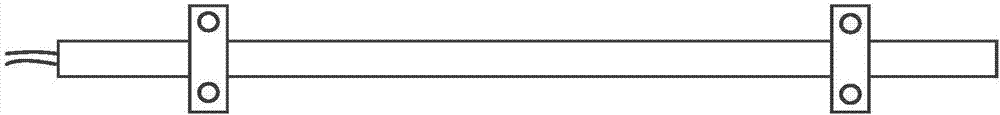

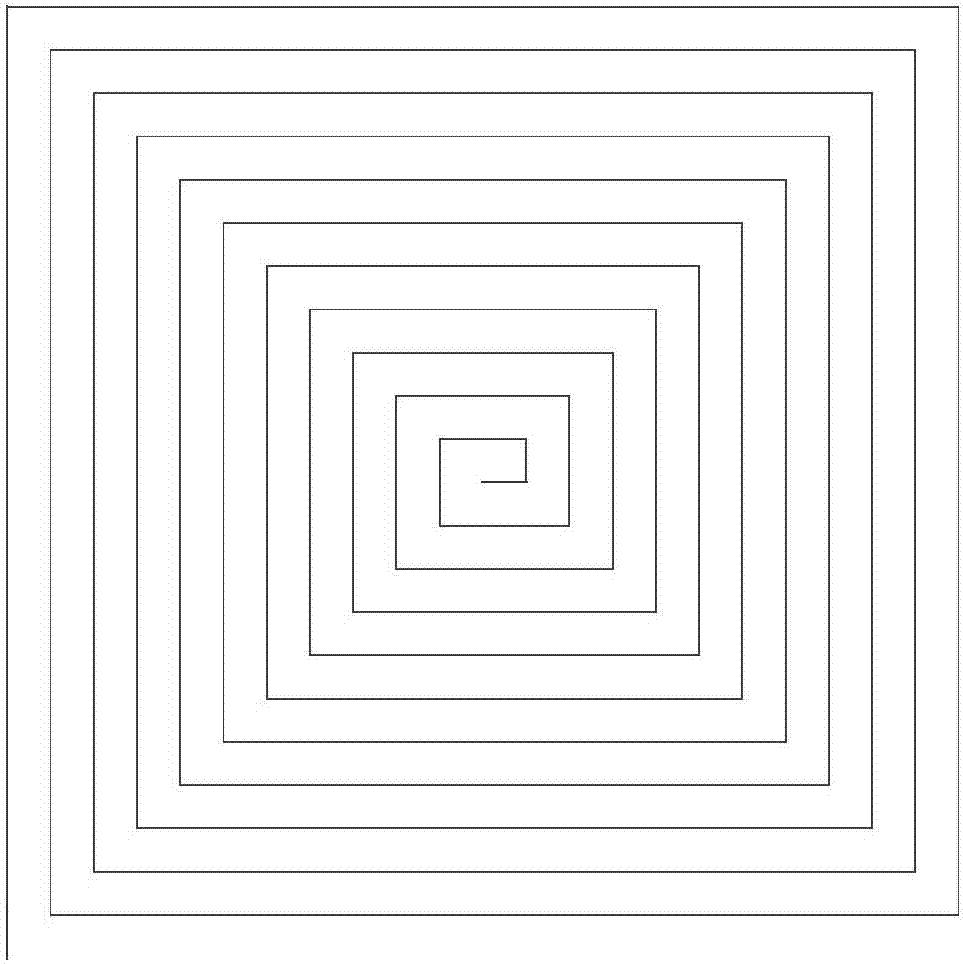

[0017] Specific implementation mode 1. Combination Figure 1 to Figure 4 Describe this embodiment, a high-density modular magnetic torque device applied to micro-nano satellites, including X-axis magnetic rod 1 and Y-axis magnetic rod 2, Z-axis hollow magnetic torque device 4, and a three-axis magnetic torque device control and drive circuit board (PCB board) 3, the X-axis magnetic bar 1 and the Y-axis magnetic bar 2 are vertically installed on the plane of the PCB board 3 . The coil input end and output end 5 of the X-axis magnetic bar 1 , the coil input end and output end 6 of the Y-axis magnetic bar 2 , and the coil input end and output end 7 of the Z-axis hollow magnetic torque device 4 are connected to the PCB board 3 . The PCB board 3 includes a three-axis magnetic torque device control and drive circuit, and the three-axis magnetic torque device control and drive circuit includes a main control chip, an AD sampling circuit, a communication circuit, a three-way H-bridge ...

specific Embodiment approach 2

[0019] Specific embodiment 2. This embodiment is the design method of the high-density modular magnetic torque device applied to the micro-nano satellite described in the specific embodiment 1. The method is realized by the following steps:

[0020] Step 1. According to the magnetic control requirements of micro-nano satellites, obtain the same magnetic moment index of the X-axis magnet bar and the Y-axis magnet bar, that is, M xy 1Am 2 , according to the magnetic moment index M of the X-axis magnetic rod and the Y-axis magnetic rod xy , design the X-axis magnetic rod and the Y-axis magnetic rod to have the same length and diameter, that is, the length L of the magnetic rod is 9cm and the diameter d is 6mm, M xy The formula is expressed as:

[0021] In the formula, B is the average magnetic flux density in the rod core, V is the volume of the magnetic rod, μ is the effective magnetic permeability of the magnetic rod, N xy is the total number of turns of the magnetic bar c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com