Special protection pipe for ground well holes in gas drainage in mining areas

A technology for gas drainage and mining areas, which is applied in the field of special protection pipes for gas drainage ground wells in mining areas, and can solve problems such as rock force damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

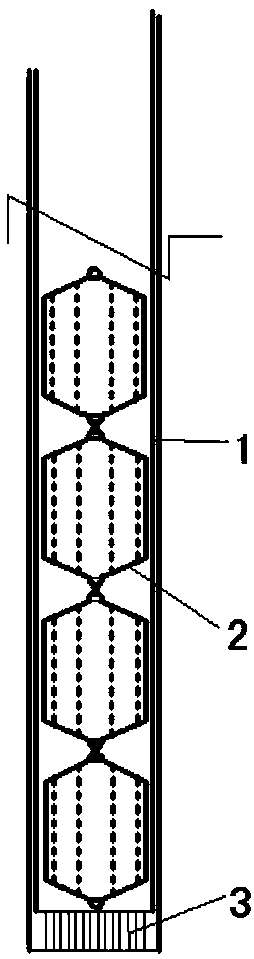

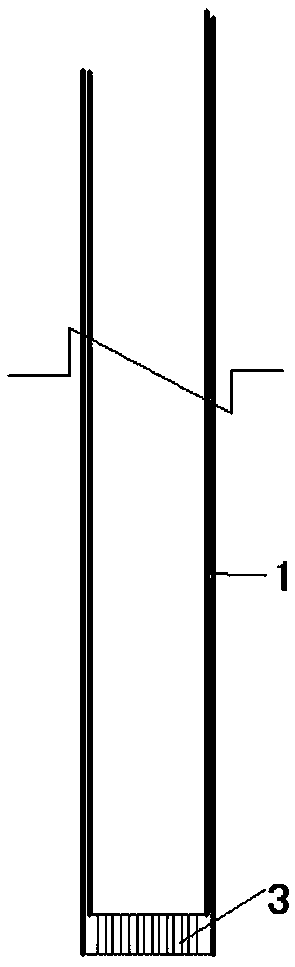

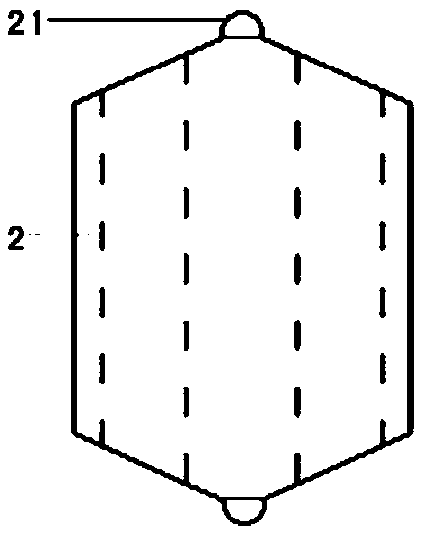

[0028] Such as Figure 1 to Figure 7 As shown, this embodiment provides a special protection pipe for gas drainage ground well holes in the mining area, and the special protection pipe for gas drainage ground well holes in the mining area is arranged in the ground well holes for gas drainage in the mining area. In the process of gas drainage in the mining area, in the ground drilling (well) hole, a stainless steel casing with certain flexibility is installed at the position where the rock formation is prone to lateral movement, up and down expansion and stretching, lateral extrusion, and longitudinal extrusion. . The stainless steel sleeve 1 can achieve a certain degree of flexible deformation. A chain is arranged inside the casing 1 , and the chain can slide relative to the casing 1 . The chain includes several chain cylinders 2 and connecting pieces that movably connect adjacent chain cylinders 2. The chain can be bent with the bending of the sleeve 1, and automatically sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com