Waste heat boiler capable of rapidly cooling and utilizing gas generated by high-thermal reaction mechanism

A waste heat boiler and reaction technology, which is applied in the field of production and processing, can solve problems such as waste of resources, and achieve the effect of reducing air pollution and speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

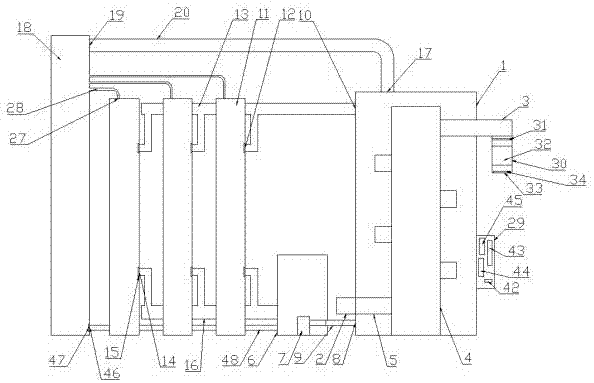

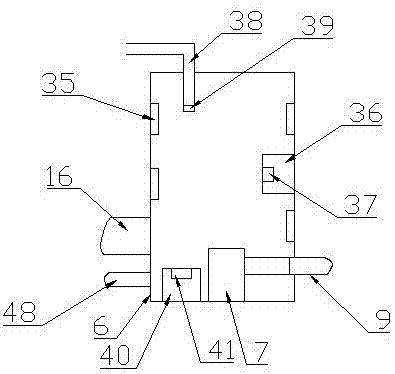

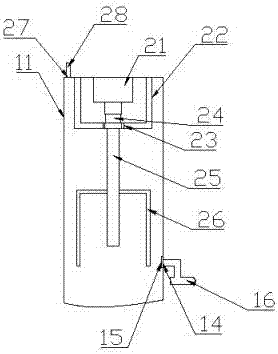

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5As shown, a waste heat boiler that rapidly cools and utilizes gas generated by a high-temperature reaction mechanism includes a boiler body 1 fixedly installed on the ground, and a high-temperature gas circulation mechanism is provided inside the boiler body 1. The above-mentioned high-temperature gas circulation mechanism consists of an air inlet 2 fixedly installed on one side below the boiler, an air outlet 3 fixedly installed on the other side above the boiler, a support column 4 fixedly installed in the center of the inner lower surface of the boiler body 1, and one end connected to the inlet. The gas port 2 is fixedly connected to the gas outlet 3 at the other end and is screwed on the outer surface of the support column 4. The air circulation pipe 5 is composed of a gas purification mechanism fixedly installed on the gas outlet 3. The boiler body 1 is equi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap