a water mixing device

A water mixing and water pump technology, which is applied in hot water central heating systems, household heating, space heating and ventilation details, etc., can solve the problems of increasing the hidden safety hazards of pipeline connections, difficulty in market promotion, and complex assembly processes. Easy on-site construction and assembly, favorable for market promotion, and the effect of small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

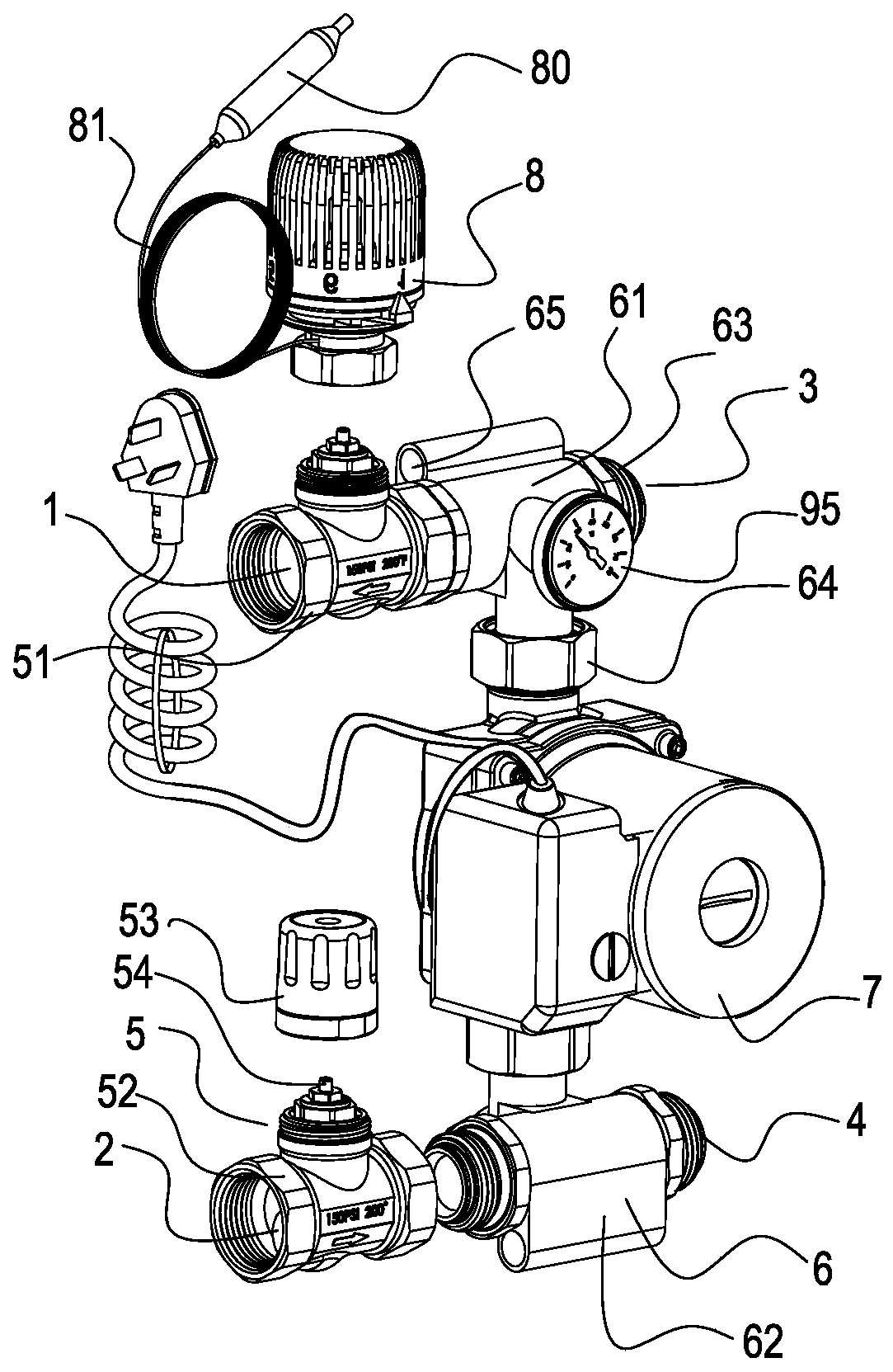

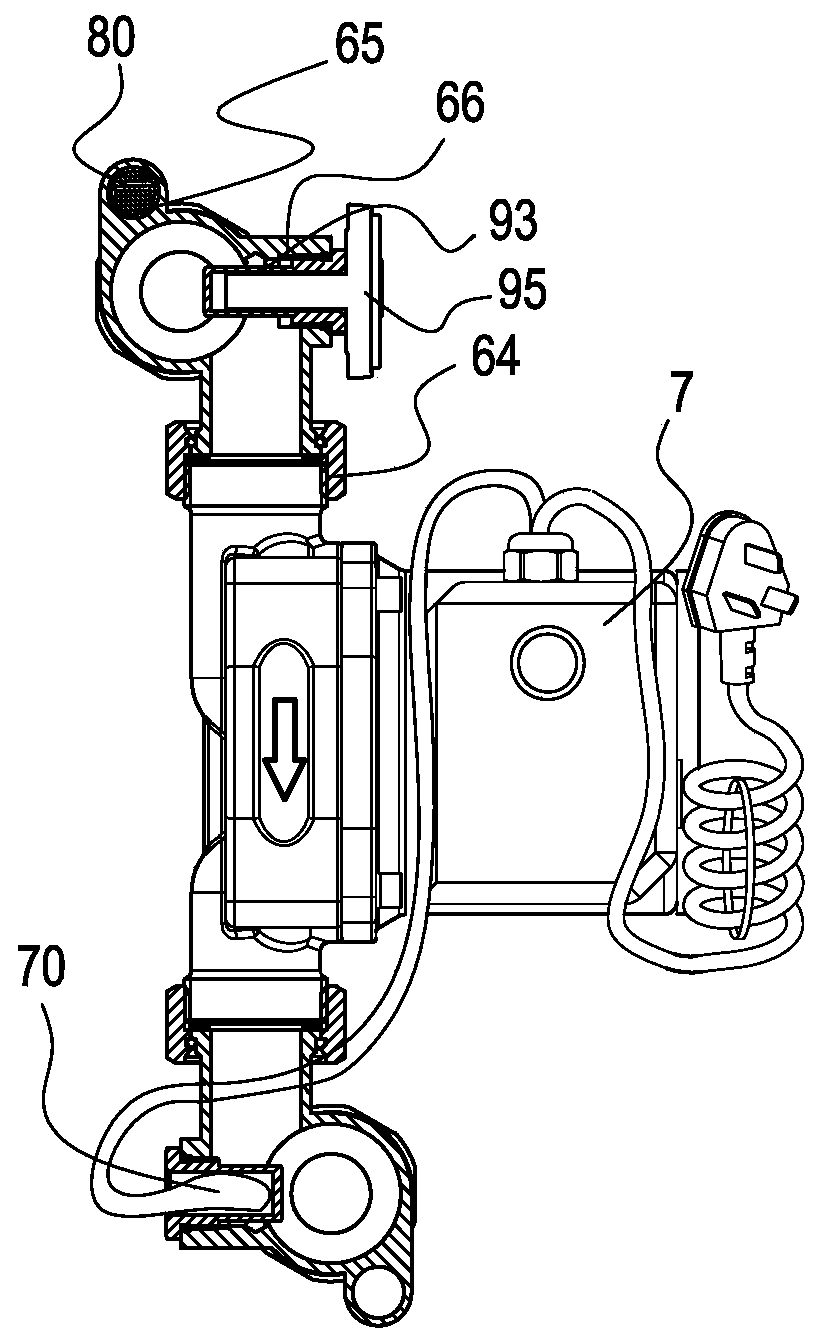

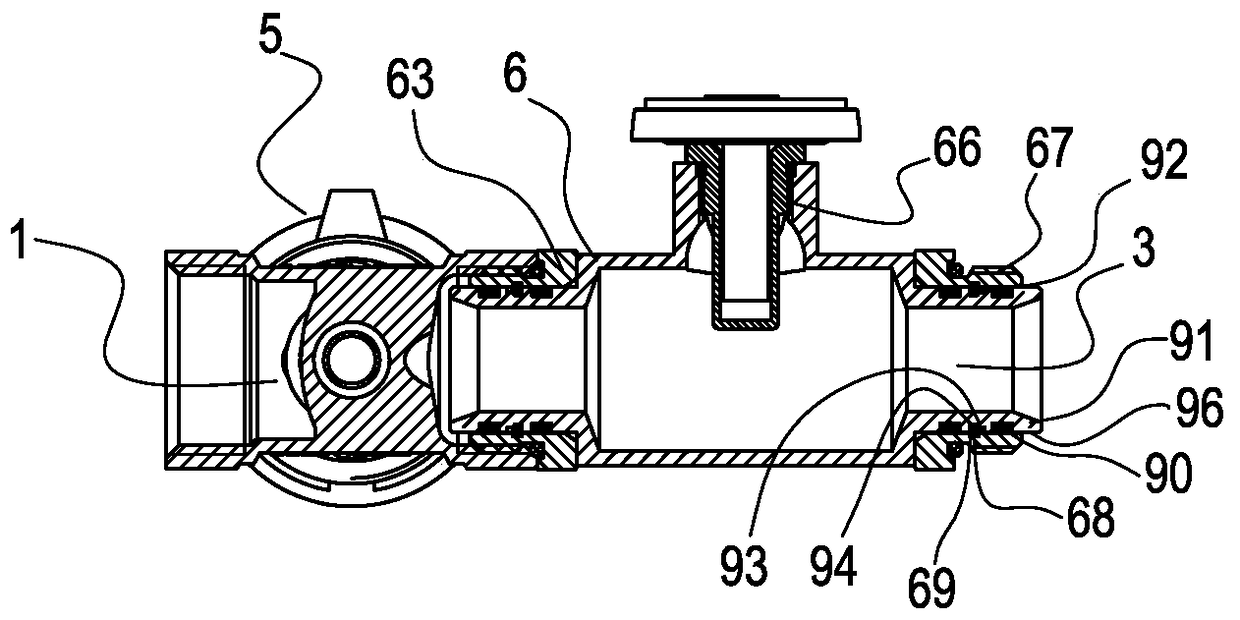

[0018] Such as Figure 1 to Figure 3 As shown, a water mixing device is provided with a high-temperature water inlet 1 and a low-temperature return water port 2 at one end, and a cooling return port 3 and a water mixing outlet 4 at the other end; the water mixing device includes two cut-off ports with the same structure and size. The valve 5, and the two connection assemblies 6 with the same structural size that are respectively connected and fixed with the stop valve 5, a water pump 7 is also provided between the eccentric threaded ends 64 of the two connection assemblies 6; the stop valve 5 is divided into the first The stop valve 51 and the second stop valve 52; one of the stop valves 5 is provided with a temperature-adjusting temperature package 8 with a temperature sensing probe 80; and the installation direction of the first stop valve 51 and the second stop valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com