A cable insulator thermal breakdown voltage determining method and device

A technology for cable insulation and determination methods, applied in the direction of testing dielectric strength, etc., can solve problems affecting power transmission safety, inaccurate evaluation of thermal breakdown conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

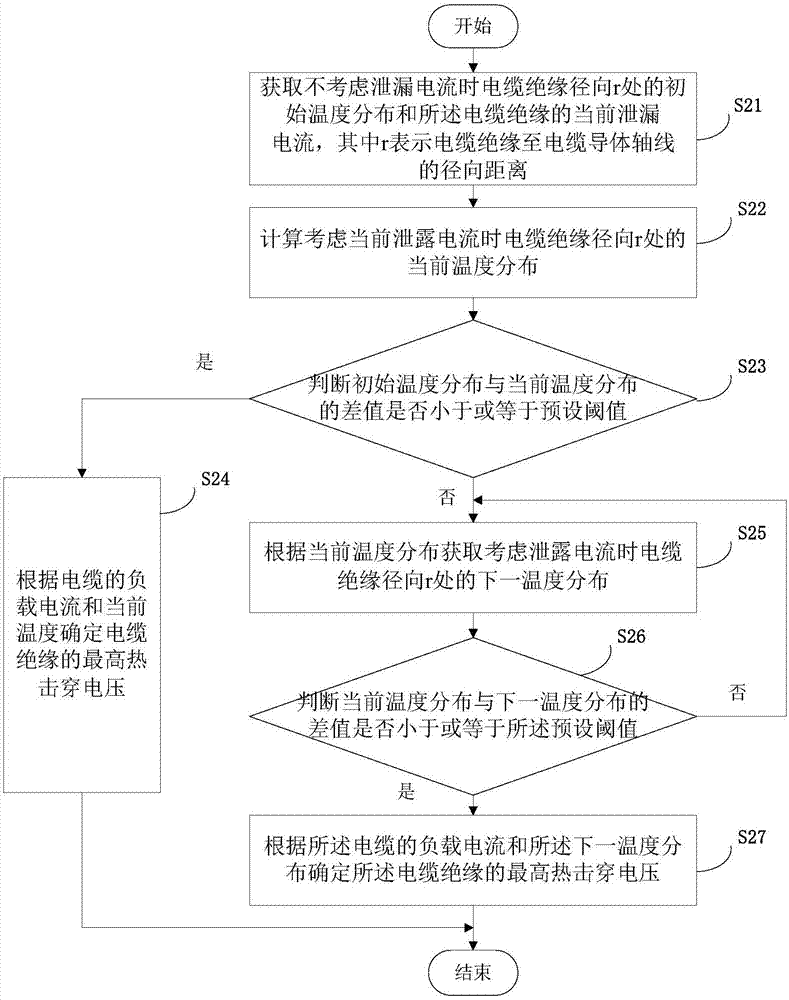

[0083] This embodiment provides a method for determining the thermal breakdown voltage of cable insulation, which is suitable for evaluating the thermal breakdown of various cables, such as figure 2 As shown, the method includes the following steps:

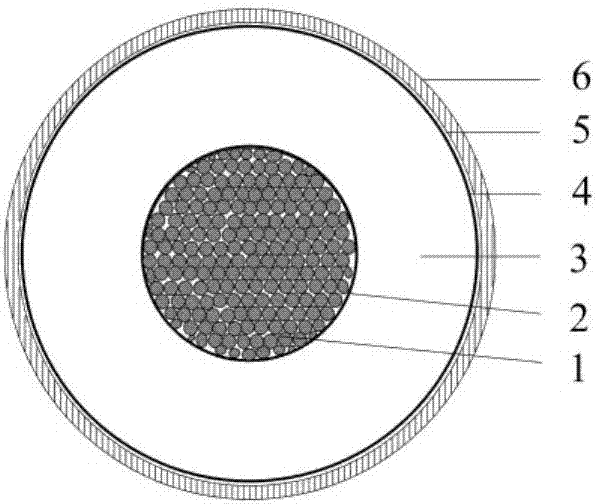

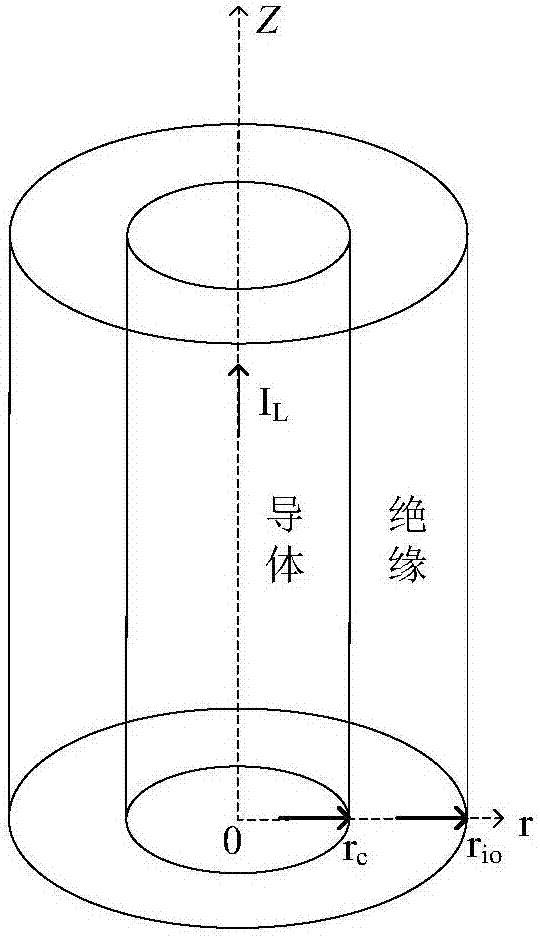

[0084] S21: Obtain the initial temperature distribution at the radial direction r of the cable insulation and the current leakage current of the cable insulation when the leakage current is not considered, where r represents the radial distance from the cable insulation to the axis of the cable conductor; here, the initial temperature distribution That is, in order to ignore the loss caused by the leakage current of the cable insulation, the initial temperature distribution at the radial direction r of the cable insulation is assumed under the condition that the temperature of the cable conductor and the metal sheath is constant. Specifically, when ignoring the structure outside the metal sheath of the DC cable, the structure of...

Embodiment 2

[0129] This embodiment provides a cable insulation thermal breakdown voltage determination device, such as Figure 4 As shown, the device includes: a first acquisition module 41, a calculation module 42, a first judgment module 43, a first determination module 44, a second acquisition module 45, a second judgment module 46, a repetition module 47 and a second determination module 48 , the main functions of each module are as follows:

[0130] The first acquisition module 41 is configured to acquire the initial temperature distribution at the radial direction r of the cable insulation and the current leakage current of the cable insulation when the leakage current is not considered, where r represents the radial distance from the cable insulation to the axis of the cable conductor; For details, refer to the detailed description of step S21 in Embodiment 1.

[0131] The calculation module 42 is configured to calculate the current temperature distribution at the radial direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com