Furnace transformer figure-8-shaped low-voltage coil looping device

A technology for electric furnace transformers and low-voltage coils. It is applied in the direction of transformers, inductors/transformers/magnets, inductors, etc. It can solve the problems of poor versatility of tooling, inability to accurately guarantee the size of the center distance, labor and materials, and reduce production and manufacturing. The effect of low cost, strong versatility and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

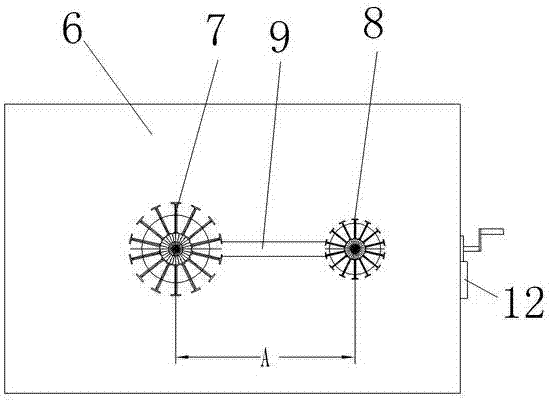

[0017] Such as image 3 , Figure 4 with Figure 5 As shown, the present invention includes a coil set platform 6, a first adjustable winding post 7, a second adjustable winding post 8 and a transmission mechanism 11, and the first adjustable winding post 7 and the second adjustable winding post 8 The interval is located on the coil package platform 6, the first adjustable winding column 7 is fixed on the coil package platform 6, and the coil package platform 6 between the first adjustable winding column 7 and the second adjustable winding column 8 is set There is a chute 9, and the transmission mechanism 11 can drive the second adjustable winding column 8 to move around the chute 9, adjust the distance between the first adjustable winding column 7 and the second adjustable winding column 8, and then adjust The center distance A between the main and series transformer coils.

[0018] The side of the coil assembly platform 6 is provided with a dial 12, the dial 12 is linked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com