Battery control device and battery control system

A battery control and battery technology, applied in the direction of battery circuit devices, circuit devices, secondary batteries, etc., can solve problems such as unstable function operation, achieve the effect of enhancing monitoring and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

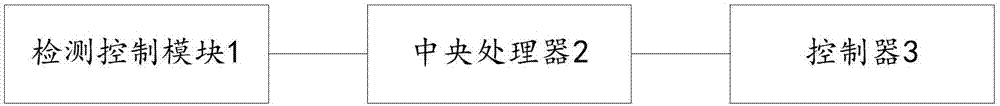

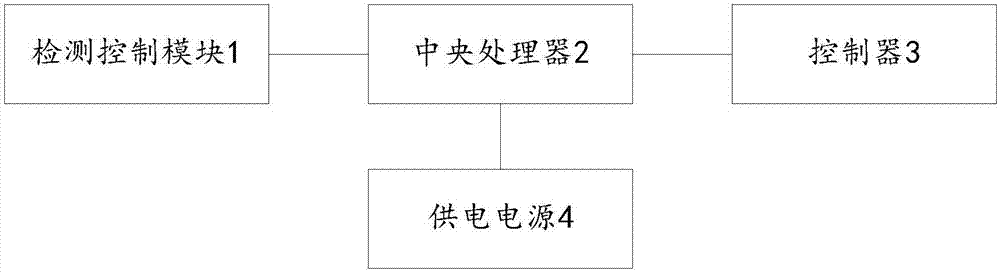

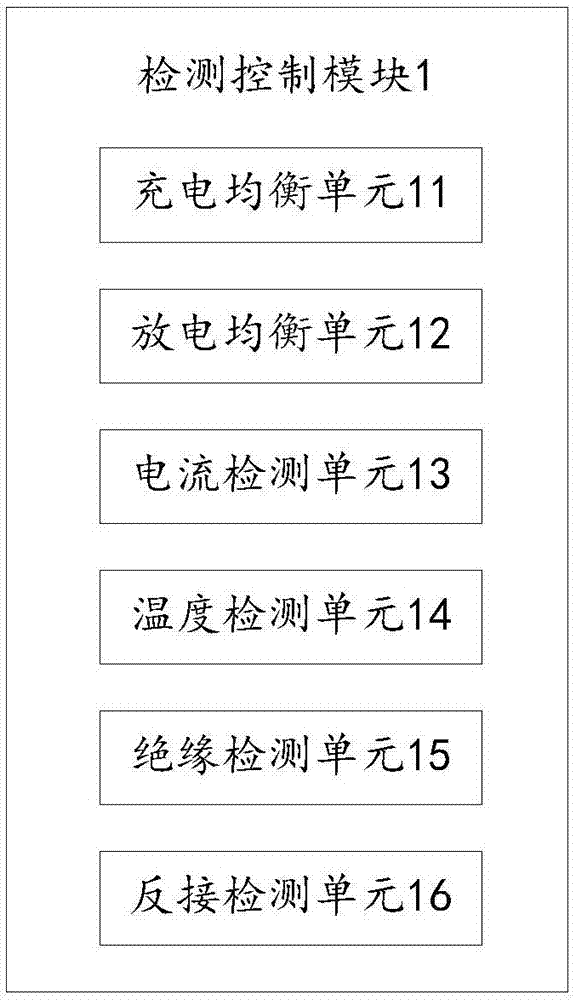

[0051] see figure 1 , figure 2 and image 3 , the battery control device 6 proposed in this embodiment specifically includes: a detection control module 1, a central processing unit 2 and a controller 3 connected in sequence, in the battery control device 6, the detection control module 1 is used for real-time monitoring of the battery pack to be tested 5 performance parameters, and the detection control module 1 can also convert the performance parameters into a performance monitoring signal and send it to the central processing unit 2, and then the central processing unit 2 is used to compare whether the performance monitoring signal is consistent with the pre-stored standard monitoring signal , and, when the comparison results are inconsistent, the central processing unit 2 generates a difference signal, and then the controller 3 is used to control the battery pack 5 to be tested after receiving the difference signal. What needs to be explained here is that in the actual...

Embodiment 2

[0066] see Figure 4 , the present embodiment provides a battery control system including: a battery pack 5 and the above-mentioned battery control device 6, in the battery control system, the battery pack 5 and the battery control device 6 are electrically connected, and when in use, the battery control device 6 is used to control The battery pack 5 is tested, and the performance signal of the battery pack 5 obtained from the test is processed. What needs to be explained here is that the performance signals include overvoltage, undervoltage, overcurrent, short circuit, reverse connection and so on.

[0067] To sum up, the battery control system provided by this embodiment includes: a battery pack 5 and the above-mentioned battery control device 6. In this battery control system, the battery pack 5 and the battery control device 6 are electrically connected. During operation, the battery control device 6 is used to test the battery pack 5 and process the performance signal ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com