Push-pull type load-bearing sled suitable for burst resistance training and push-pull method

A push-pull and sled technology, applied to heavy objects, skis, snowboards, etc., can solve problems such as laborious weight plates, difficult barbell weight plates to take out, fall training personnel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

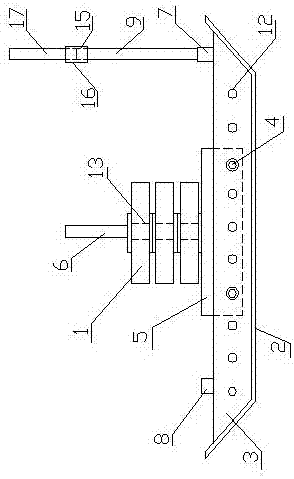

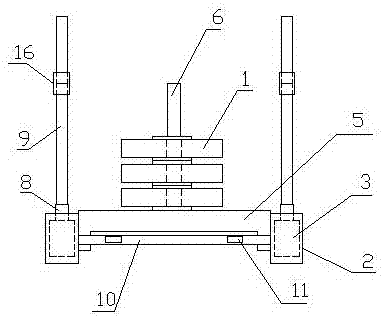

Embodiment 1

[0022] A push-pull weight-bearing sled suitable for explosive resistance training, which consists of: a barbell weight plate 1, a sled outer frame 2 and a support frame 3 of a trapezoidal structure, and vertical welding on the inner frame surface of the two sled outer frames There are two trapezoidal structure support frames, the inner sides of the two trapezoidal structure support frames are connected to the load-bearing platform 5 through the hexagonal bolt assembly 4, and the middle position of the load-bearing platform is welded with a load-bearing insertion rod 6, At least one of at most six of the barbell load plates is inserted into the load inserting rod, and a sleeve 7 is welded on the upper side of the support frame of the trapezoidal structure, and a second sleeve is welded on the upper side of the other side 8. A push-pull rod 9 is vertically inserted into the sleeve, a small-diameter barbell weight plate can be inserted into the second sleeve, and a rope crossbeam ...

Embodiment 2

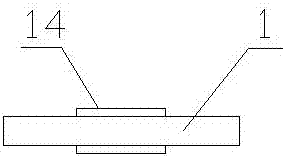

[0024] According to the push-pull weight-bearing sled suitable for explosive resistance training described in Embodiment 1, a circular jack 13 is opened at the center of the circle on the barbell weight-bearing plate, and circular rings are welded on the upper and lower surfaces of the barbell weight-bearing plate The buffer groove 14 of structure, the diameter of described buffer groove is greater than the diameter of described circular socket, and the height of described buffer groove is 20mm.

Embodiment 3

[0026] According to the push-pull weight-bearing sled suitable for explosive resistance training described in embodiment 1 or 2, one end of the push-pull rod is processed with an external thread structure with a length of 35-65mm, and the inner side of the corresponding position is processed with a 40mm deep internal thread structure , the external thread structure is screwed with an internal thread sleeve 15, and the other end of the internal thread sleeve is screwed with an extended push-pull rod 16, and one end of the extended push-pull rod has a column structure 17, and the column structure The external thread structure on the piece is screwed into the internal thread structure of the push-pull rod, and the outer arc surface of the extended pull rod is processed with an external thread structure with a length of 35-65mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com