Vacuum transfer assembly

A component and vacuum technology, applied in the field of vacuum transfer components, can solve problems such as loss of resolution, icing of brackets, and no new possibility of vacuum transfer brackets, etc., and achieve the effect of reduced vibration sensitivity and good resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

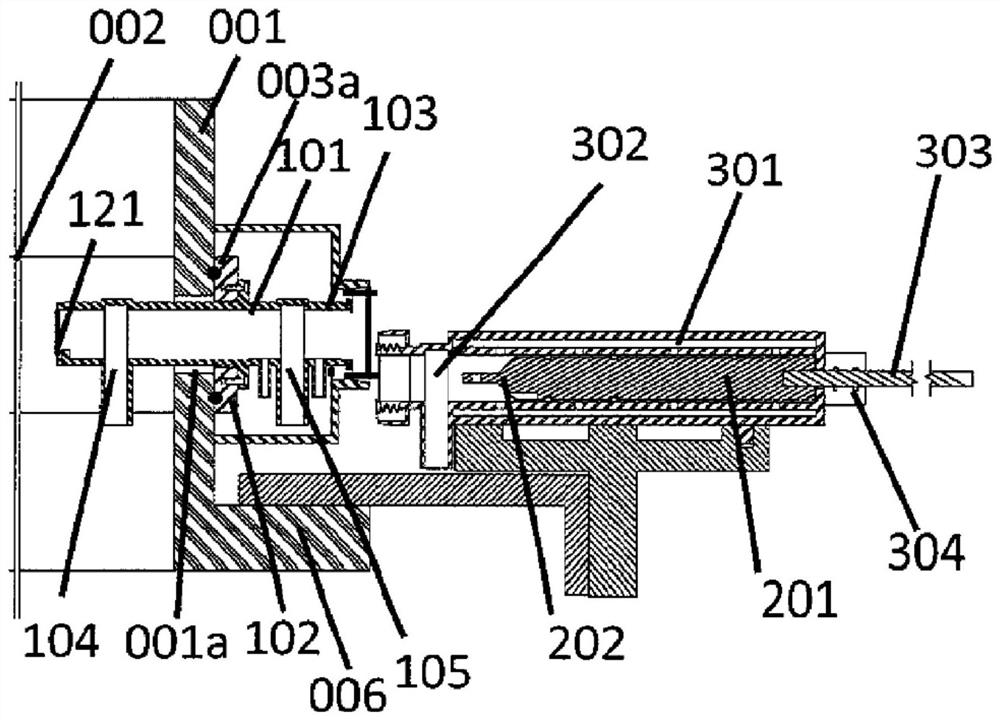

[0035] In a first aspect, the invention relates to a vacuum transfer assembly according to aspect 1 .

[0036] In an exemplary embodiment, the present assembly may include a loading rod 303 that is connected to the sample holder 201 to allow controlled loading of the sample holder to its final position in the TEM and vice versa, which may be computer controlled.

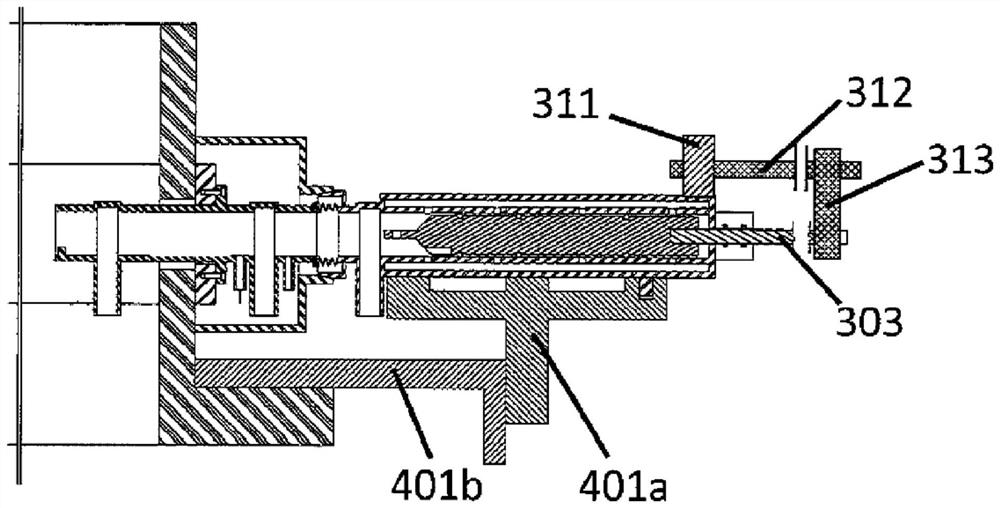

[0037] In an exemplary embodiment of this assembly, at least one length of the vacuum housing may be greater than the length of the outer tube, the vacuum housing valve may be located at the first end of the vacuum housing, and wherein, at the other end of the vacuum housing, a There is a narrow section including a fourth seal 304 that provides a passage for either the loading rod or the insertion rod.

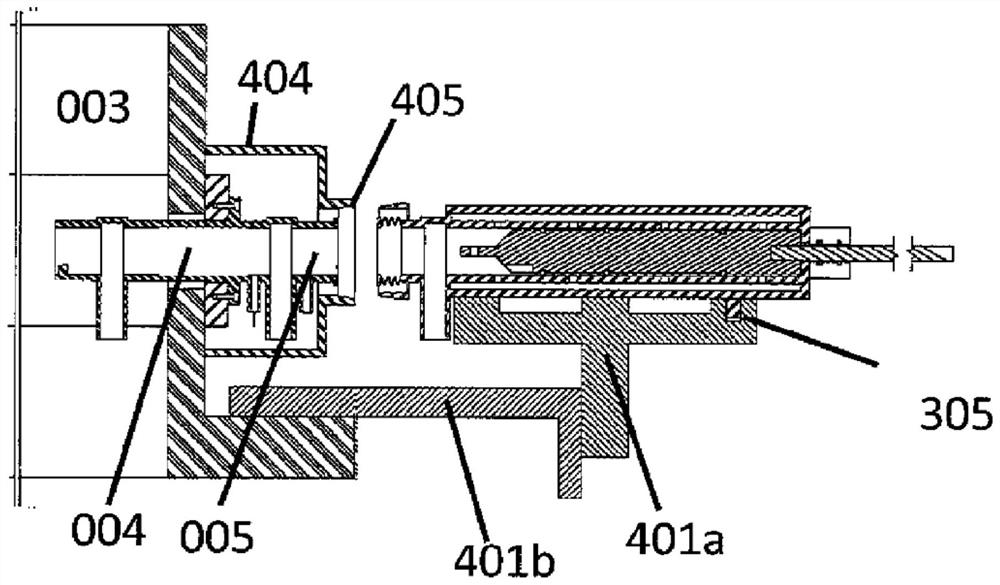

[0038]This assembly includes at least one of a holder 405 for attachment to the lens barrel 001 of the microscope, a holder 121, and a wave portion for fixing the alignment portion of the vacuum housing 310 to the TE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com